Contents

Rectangular Domain Meshing

1. Outline

This program has been made to contribute the creating test data with 4 nodes element.

Number of nodes, number of elements, element-node relationships and node coordinate are established by inputting the dimensions of rectangular domain and division number of each side. THe model drawing is also created to confirm the generated mesh data.

Following site is very useful for the treatment of 'matplotlib paches'.

http://matthiaseisen.com/matplotlib/

2. Program for rectangular domain meshing

| Program name | Description |

|---|

| py_rectmesh.py | Program for rectangular domain meshing |

3. Command format for execution

python py_rectmesh.py aa bb nn mm x0 y0 > out.txt

| aa | : length of domain in x-direction |

| bb | : length of domain in y-direction |

| nn | : division number of domain in x-direction |

| mm | : division number of domain in y-direction |

| x0 | : x-coordinate of left-bottom of domain |

| y0 | : y-coordinate of left-bottom of domain |

| out.txt | : Output file name |

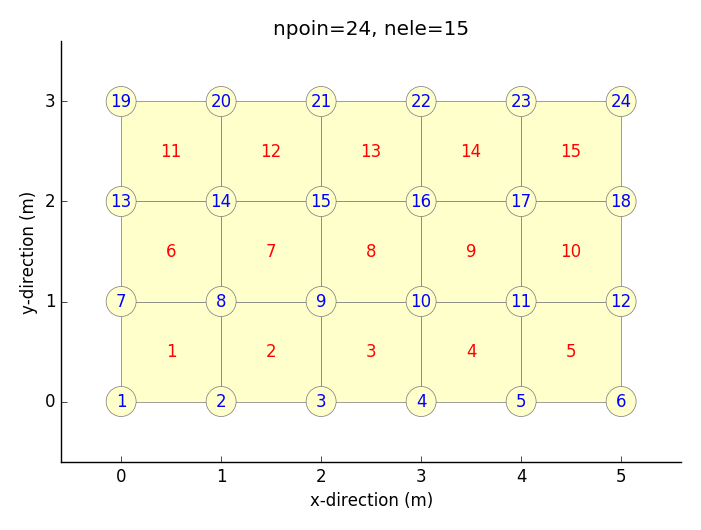

4. Output sample

4.1 Execution command

python py_rectmesh.py 5 3 5 3 0 0 > _test.txt

4.2 Output data

Number of nodes, number of elements, element-node relationship and node coordinats are included in output data.

In the last column of a row of element-node relationship, element numbers are writen as reference data.

And in the last column of a row of node coordinates, node numbers are writen as reference data.

24 15 # number of nodes, number of elements

1 2 8 7 1 # element-node relationship

2 3 9 8 2 # node-1, node-2, node-3, node-4, element_number(reference)

3 4 10 9 3

4 5 11 10 4

5 6 12 11 5

7 8 14 13 6

8 9 15 14 7

9 10 16 15 8

10 11 17 16 9

11 12 18 17 10

13 14 20 19 11

14 15 21 20 12

15 16 22 21 13

16 17 23 22 14

17 18 24 23 15

0.000 0.000 1 # x-coordinate, y-coordinate, node_number(reference)

1.000 0.000 2

2.000 0.000 3

3.000 0.000 4

4.000 0.000 5

5.000 0.000 6

0.000 1.000 7

1.000 1.000 8

2.000 1.000 9

3.000 1.000 10

4.000 1.000 11

5.000 1.000 12

0.000 2.000 13

1.000 2.000 14

2.000 2.000 15

3.000 2.000 16

4.000 2.000 17

5.000 2.000 18

0.000 3.000 19

1.000 3.000 20

2.000 3.000 21

3.000 3.000 22

4.000 3.000 23

5.000 3.000 24

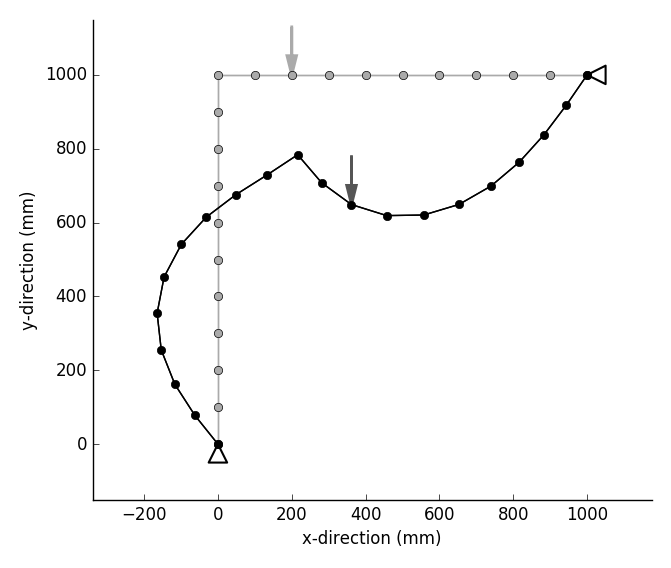

4.3 Output drawing

2D Frame Analysis

1. Outline

- This is a program for 2D frame analysis. Elastic and small displacement problems can be treated.

- Beam element with 2 nodes is used. 1 node has 3 degrees of freedom in horizontal displacement, vertical displacement and rotation.

- Nodal external force, nodal forced displacement, nodal temperature change and inertia force for element can be given as loads.

- In coordinate system, x-direction is defined as right-direction, y-direction is defined as upward direction and counterclockwise direction is defined as positive in rotation.

- Simultaneous linear equations are solved using numpy.linalg.solve(A, b).

- Input/Output file name can be defined arbitrarily with the format of space separater and those are inputted as command line arguments of a terminal.

| Valid boundary conditions |

|---|

| Item | Description |

|---|

| External force | Specify the loded nodes and load values |

| Temperature change | Specify the temperature change at all nodes |

| Inertia force | Specify the inertia force as a ratio to the gravity acceleration in horizontal and vertical direction in the material properties data |

| Forced displacement | Specify the nodes with forced displacements and those values. Any values can be applied including zero |

2. FEM program

3. Command format for FEM analysis execution

python3 py_fem_frame.py inp.txt out.txt

| inp.txt | : Input data file (separated by space) |

| out.txt | : Output data file (separated by space) |

4. Input data format

npoin nele nsec npfix nlod # Basic values for analysis

E A I alpha gamma gkh gkv # Material properties

..... (1 to nsec) ..... #

node_1 node_2 isec # Element connectivity, material set number

..... (1 to nele) ..... #

x y deltaT # Node coordinate, temperature change of node

..... (1 to npoin) ..... #

lp fix_x fix_y fix_r rdis_x rdis_y rdis_r # Restricted node and restrict conditions

..... (1 to npfix) ..... #

lp fp_x fp_y fp_r # Loaded node and loading conditions

..... (1 to nlod) ..... # (omit data input if nlod=0)

| npoin, nele, nsec | : number of nodes, number of elements, number of material sets |

| npfix, nlod | : number of restricted nodes, number of loaded nodes |

| E, A, I, alpha | : elastic modulus, section area, moment of inertia, thermal expansion coefficient |

| gamma, gkh, gkv | : unit weight, horizontal and vertical acceleration (ratio to 'g') |

| node_1, node_2, isec | : node-1, node-2, material set number |

| x, y, deltaT | : x-coordinate, y-coordinate, nodal temperature change |

| lp, fix_x, fix_y, fix_r | : node, kind of restriction in x, y and rotation (0: free, 1: fixed) |

| rdis_x, rdis_y, rdis_r | : forced displacement in x, y and rotation (input zero even if no-restriction) |

| lp, fp_x, fp_y, fp_r | : loaded node, loads in x, y and rotation |

5. Output data format

npoin nele nsec npfix nlod

(Each value of above)

sec E A I alpha gamma gkh gkv

sec : Material number

E : Elastic modulus

A : Section area

I : Moment of inertia

alpha : Thermal expansion coefficient

gamma : Unit weight

gkh : Acceleration in horizontal direction (ratio to g)

gkv : Acceleration in vertical direction (ratio to g)

..... (1 to nsec) .....

node x y fx fy fr deltaT kox koy kor

node : Node number

x : x-coordinate

y : y-coordinate

fx : Load in x-direction

fy : Load in y-direction

fr : Moment load

deltaT : Temperature change of node

kox : Index of restriction in x-direction (0: free, 1: fixed)

koy : Index of restriction in y-direction (0: free, 1: fixed)

kor : Index of restriction in rotation (0: free, 1: fixed)

..... (1 to npoin) .....

node kox koy kor rdis_x rdis_y rdis_r

node : Node number

kox : Index of restriction in x-direction (0: free, 1: fixed)

koy : Index of restriction in y-direction (0: free, 1: fixed)

kor : Index of restriction in rotation (0: free, 1: fixed)

rdis_x : Given displacement in x-direction

rdis_y : Given displacement in y-direction

rdis_r : Given displacement in rotation

..... (1 to npfix) .....

elem i j sec

elem : Element number

i : Node number of start point

j : Node number of end point

sec : Material number

..... (1 to nele) .....

node dis-x dis-y dis-r

node : Node number

dis-x : Displacement in x-direction

dis-y : Displacement in y-direction

dis-r : Displacement in rotation

..... (1 to npoin) .....

elem N_i S_i M_i N_j S_j M_j

elem : Element number

N_i : Axial force of node-i

S_i : Shear force of node-i

M_i : Moment of node-i

N_j : Axial force of node-j

S_j : Shear force of node-j

M_j : Moment of node-j

..... (1 to nele) .....

n=(total degrees of freedom) time=(calculation time)

| dis-x, dis-y, dis-r | : displacements in x, y and rotation |

| N, S, M | : axial force, shearing force, moment |

| n | : Total degrees of freedom (the number of the variables) |

| time | : Calculation time |

6. Output sample

6.1 Input data sample and auxiliary program

| Program name | Description |

|---|

| inp_frm.txt | Input data sample for FEM analysis |

| py_fig_force.py | Drawing program of section force diagrams (matplotlib) |

6.2 Outline of sample analysis model

Sample analysis model is a concrete box culvert under the vertical load, lateral soil pressure and uplift. Model is simply supported below the 3 walls.

6.3 Execution command for FEM analysis and drawing

python3 py_fem_frame.py inp_frm.tst out_frm.txt

python3 py_fig_force.py out_frm.txt

| out_frm.txt | : output data file of FEM analysis (saparated by space) |

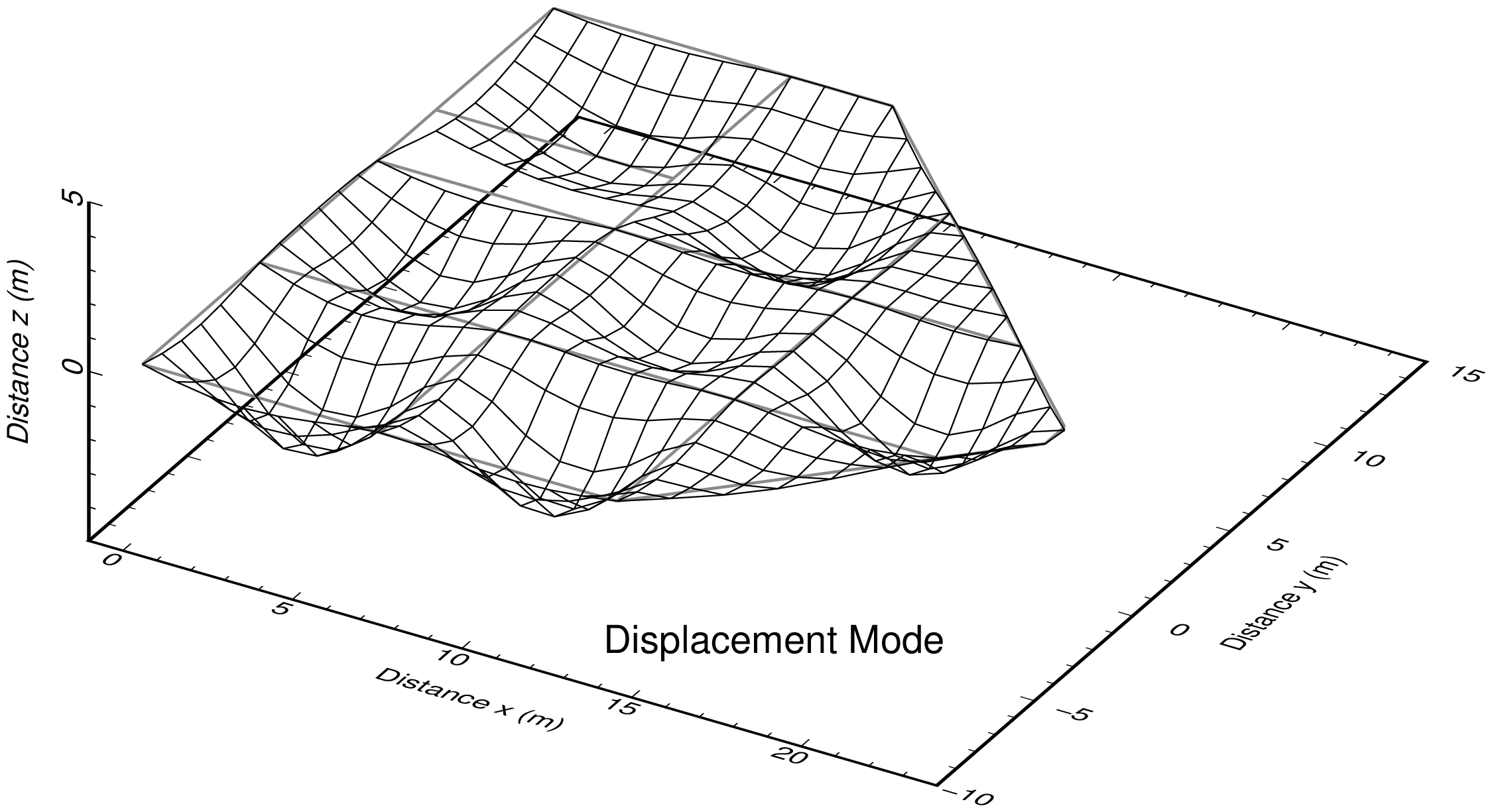

Section force diagram drawong program creates following image files automatically.

| fig_dis.png | : displacement mode diagram |

| fig_axi.png | : axial force diagram |

| fig_she.png | : shearing force diagram |

| fig_mom.png | : moment diagram |

The commands for specifing drawing range and scale should be re-writed if necessary.

axmin=np.min(x)

axmax=np.max(x)

aymin=np.min(y)

aymax=np.max(y)

midx=0.5*(axmin+axmax)

midy=0.5*(aymin+aymax)

dr=np.min([axmax-axmin,aymax-aymin])

scl_dis=0.2*dr

scl_axi=0.2*dr

scl_she=0.2*dr

scl_mom=0.3*dr

ddmax=np.max([scl_dis,scl_axi,scl_she,scl_mom])

xmin=midx-(midx-axmin+ddmax)*1.1

xmax=midx+(axmax-midx+ddmax)*1.1

ymin=midy-(midy-aymin+ddmax)*1.1

ymax=midy+(aymax-midy+ddmax)*1.6

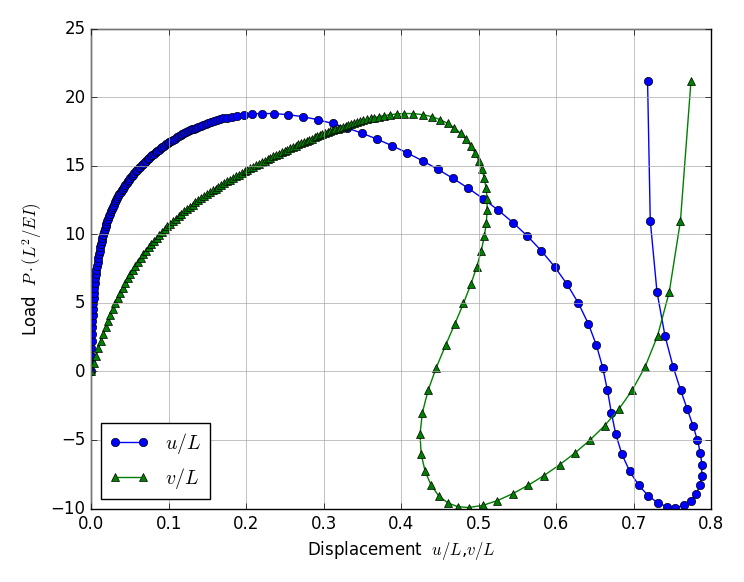

6.4 Sample of section force diagrams

2D Truss Analysis

1. Outline

- This is a program for 2D truss analysis. Elastic and small displacement problems can be treated.

- Truss element with 2 nodes is used. 1 node has 2 degrees of freedom in horizontal displacement and vertical displacement.

- Nodal external force, nodal forced displacement, nodal temperature change and inertia force for element can be given as loads.

- In coordinate system, x-direction is defined as right-direction, y-direction is defined as upward direction.

- Simultaneous linear equations are solved using numpy.linalg.solve(A, b).

- Input/Output file name can be defined arbitrarily with the format of space separater and those are inputted as command line arguments of a terminal.

| Valid boundary conditions |

|---|

| Item | Description |

|---|

| External force | Specify the loded nodes and load values |

| Temperature change | Specify the temperature change at all nodes |

| Inertia force | Specify the inertia force as a ratio to the gravity acceleration in horizontal and vertical direction in the material properties data |

| Forced displacement | Specify the nodes with forced displacements and those values. Any values can be applied including zero |

2. FEM program

3. Command format for FEM analysis execution

python3 py_fem_truss.py inp.txt out.txt

| inp.txt | : Inpyt data file (separated by space) |

| out.txt | : Output data file (separated by space) |

4. Input data format

npoin nele nsec npfix nlod # Basic values for analysis

E A alpha gamma gkh gkv # Material properties

..... (1 to nsec) ..... #

node_1 node_2 isec # Element connectivity, material set number

..... (1 to nele) ..... #

x y deltaT # Node coordinate, temperature change of node

..... (1 to npoin) ..... #

lp fix_x fix_y rdis_x rdis_y # Restricted node and restrict conditions

..... (1 to npfix) ..... #

lp fp_x fp_y # Loaded node and loading conditions

..... (1 to nlod) ..... # (omit data input if nlod=0)

| npoin, nele, nsec | : number of nodes, number of elements, number of material sets |

| npfix, nlod | : number of restricted nodes, number of loaded nodes |

| E, A, alpha | : elastic modulus, section area, thermal expansion coefficient |

| gamma, gkh, gkv | : unit weight, horizontal and vertical acceleration (ratio to 'g') |

| node_1, node_2, isec | : node-1, node-2, material set number |

| x, y, deltaT | : x-coordinate, y-coordinate, nodal temperature change |

| lp, fix_x, fix_y | : node, kind of restriction in x and y direction (0: free, 1: fixed) |

| rdis_x, rdis_y | : forced displacement in x and y direction (input zero even if no-restriction) |

| lp, fp_x, fp_y | : loaded node, loads in x and y direction |

5. Output data format

npoin nele nsec npfix nlod

(Each value of above)

sec E A alpha gamma gkh gkv

sec : Material number

E : Elastic modulus

A : Section area

alpha : Thermal expansion coefficient

gamma : Unit weight

gkh : Acceleration in horizontal direction (ratio to g)

gkv : Acceleration in vertical direction (ratio to g)

..... (1 to nsec) .....

node x y fx fy fr deltaT kox koy kor

node : Node number

x : x-coordinate

y : y-coordinate

fx : Load in x-direction

fy : Load in y-direction

deltaT : Temperature change of node

kox : Index of restriction in x-direction (0: free, 1: fixed)

koy : Index of restriction in y-direction (0: free, 1: fixed)

..... (1 to npoin) .....

node kox koy kor rdis_x rdis_y rdis_r

node : Node number

kox : Index of restriction in x-direction (0: free, 1: fixed)

koy : Index of restriction in y-direction (0: free, 1: fixed)

rdis_x : Given displacement in x-direction

rdis_y : Given displacement in y-direction

..... (1 to npfix) .....

elem i j sec

elem : Element number

i : Node number of start point

j : Node number of end point

sec : Material number

..... (1 to nele) .....

node dis-x dis-y

node : Node number

dis-x : Displacement in x-direction

dis-y : Displacement in y-direction

..... (1 to npoin) .....

elem N_i S_i N_j S_j

elem : Element number

N_i : Axial force of node-i

S_i : Shear force of node-i

N_j : Axial force of node-j

S_j : Shear force of node-j

..... (1 to nele) .....

n=(total degrees of freedom) time=(calculation time)

| dis-x, dis-y | : displacements in x and y-direction |

| N, S | : axial force, shearing force |

| n | : Total degrees of freedom (the number of the variables) |

| time | : Calculation time |

Grid Girder Analysis

1. Outline

- This is a program for grid girder analysis. Elastic and small displacement problems can be treated.

- Beam element with 2 nodes is used. 1 node has 3 degrees of freedom in torsional rotation, bending rotation and vertical displacement.

- Nodal external force and nodal forced displacement can be given as loads.

- A grid girder structure shall be arranged on x-y plane in the global coordinate system.

- Axial direction of a member corresponds to x-axis of local coordinate system.

- The tortional rotation corresponds to the rotation around x-axis in local coordinate system.

- The bending rotation corresponds to the rotation around y-axis in local coordinate system.

- The deflection of grid girder corresponds to the displacement in z-direction in local coordinate system, and this value is the same as the displacement in global coordinate system.

- Simultaneous linear equations are solved using numpy.linalg.solve(A, b).

- Input/Output file name can be defined arbitrarily with the format of space separater and those are inputted as command line arguments of a terminal.

| Valid boundary conditions |

|---|

| Item | Description |

|---|

| External force | Specify the loded nodes and load values |

| Forced displacement | Specify the nodes with forced displacements and those values. Any values can be applied including zero |

2. FEM program

3. Command format for FEM analysis execution

python3 py_fem_grid.py inp.txt out.txt

| inp.txt | : Input data file (separated by space) |

| out.txt | : Output data file (separated by space) |

4. Input data format

npoin nele nsec npfix nlod # Basic values for analysis

E po A I J # Material properties

..... (1 to nsec) ..... #

node_1 node_2 isec qw # Element connectivity, material set number, load

..... (1 to nele) ..... #

x y # Node coordinate

..... (1 to npoin) ..... #

lp fix_x fix_y fix_z rdis_x rdis_y rdis_z # Restricted node and restrict conditions

..... (1 to npfix) ..... #

lp fp_x fp_y fp_z # Loaded node and loading conditions

..... (1 to nlod) ..... # (omit data input if nlod=0)

| npoin, nele, nsec | : number of nodes, number of element, number of material sets |

| npfix, nlod | : number of restricted nodes, number of loaded nodes |

| E, po, A, I, J | : elastic modulus, poisson's ratio, section area, moment of inertia, torsional constant |

| node_1, node_2, isec, qw | : node-1, node-2, material set number |

| x, y | : x-coordinate, y-coordinate |

| lp, fix_x, fix_y, fix_z | : node, kind of restriction in torsion, bending and vertical deflection (0: free, 1: fixed) |

| rdis_x, rdis_y, rdis_z | : forced displacement in tortion, bending and vertical defrection (input zero even if no-restriction) |

| lp, fp_x, fp_y, fp_z | : node, loads in tortional, bending and vertical. |

Although a shear modulus $G$ is required in the grid girder analysis, it is calculated from a elastic modulus ($E$, E) and Poisson's ratio ($\nu$, po) using following relationship in this program.

\begin{equation}

G=\cfrac{E}{2 (1+\nu)}

\end{equation}

5. Output data format

npoin nele nsec npfix nlod

(Each value of above)

sec E po A I J

sec : Material number

E : Elastic modulus

po : Poisson's ratio

A : Section area

I : Moment of inertia

J : Tortional constant

..... (1 to nsec) .....

node x y fx fy fz kox koy koz

node : Node number

x : x-coordinate

y : y-coordinate

fx : Tortional moment load around x-axis

fy : Bending moment load

fz : Vertical load

kox : Index of restriction in tortional rotationin (0: free, 1: fixed)

koy : Index of restriction in bending rotation (0: free, 1: fixed)

koz : Index of restriction in vertical direction (0: free, 1: fixed)

..... (1 to npoin) .....

node kox koy kor rdis_x rdis_y rdis_r

node : Node number

kox : Index of restriction in tortional rotationin (0: free, 1: fixed)

koy : Index of restriction in bending rotation (0: free, 1: fixed)

koz : Index of restriction in vertical direction (0: free, 1: fixed)

rdis_x : Given rotation by tortional moment

rdis_y : Given rotation by bending moment

rdis_z : Given displacement in z (vertical) direction

..... (1 to npfix) .....

elem i j sec

elem : Element number

i : Node number of start point

j : Node number of end point

sec : Material number

qw : uniformly distributed vertical load per unit length

..... (1 to nele) .....

node dis-x dis-y dis-r

node : Node number

dis-x : Rotation by tortional moment

dis-y : Rotation by bending moment

dis-z : Vertical displacement

..... (1 to npoin) .....

elem T_i M_i Q_i T_j M_j Q_j

elem : Element number

T_i : Tortional moment of node-i

M_i : Bending moment of node-i

Q_i : Shear force of node-i

T_j : Tortional moment of node-j

M_j : Bending moment of node-j

Q_j : Shear force of node-j

..... (1 to nele) .....

n=(total degrees of freedom) time=(calculation time)

| dis-x, dis-y, dis-z | : tortional rotation, bending rotation, vertical deflection |

| T, M, Q | : torque, bending moment, shearing force |

| n | : Total degrees of freedom (the number of the variables) |

| time | : Calculation time |

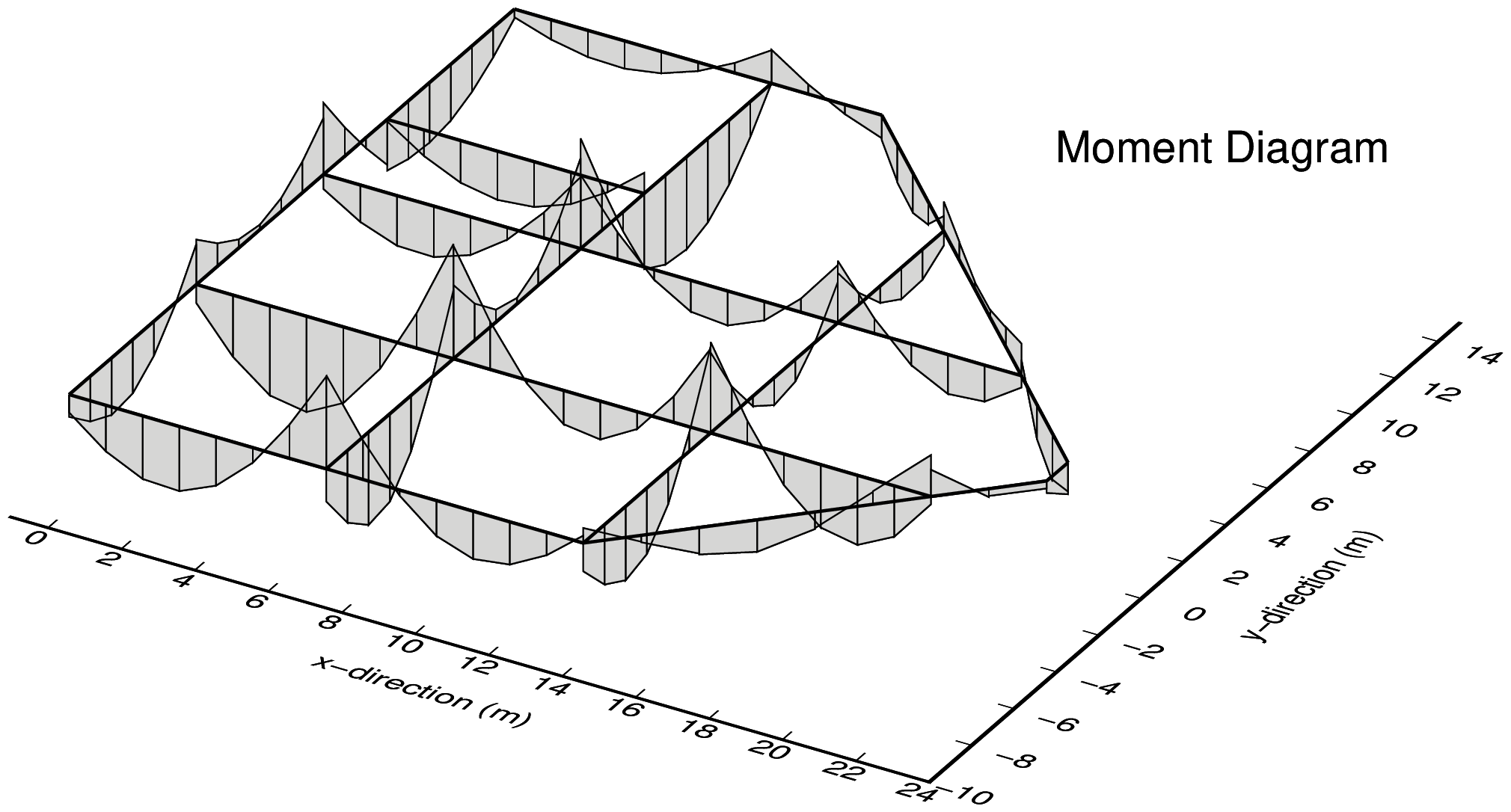

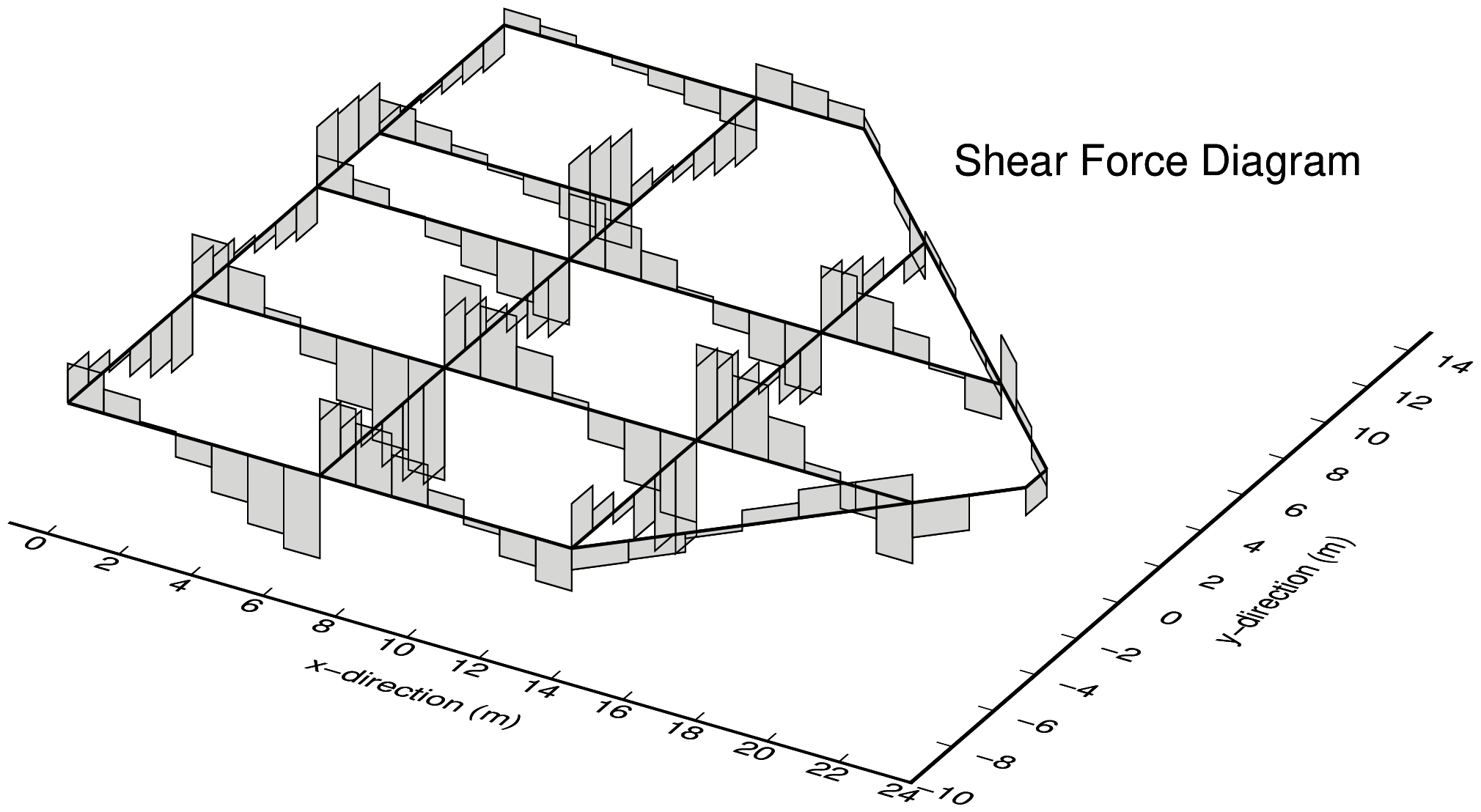

6. Output sample

6.1 Input data sample and auxiliary program

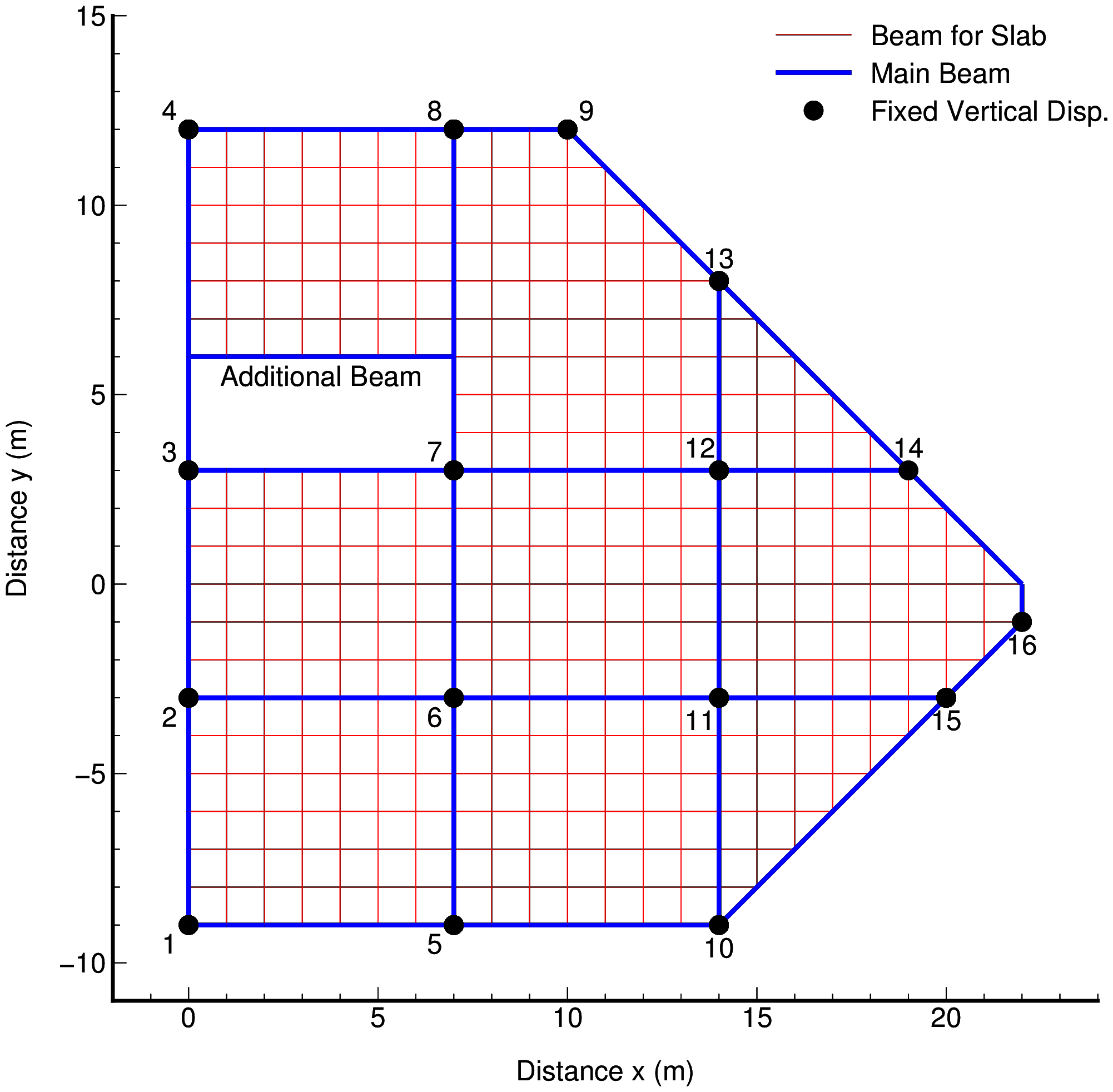

6.2 Outline of sample analysis model

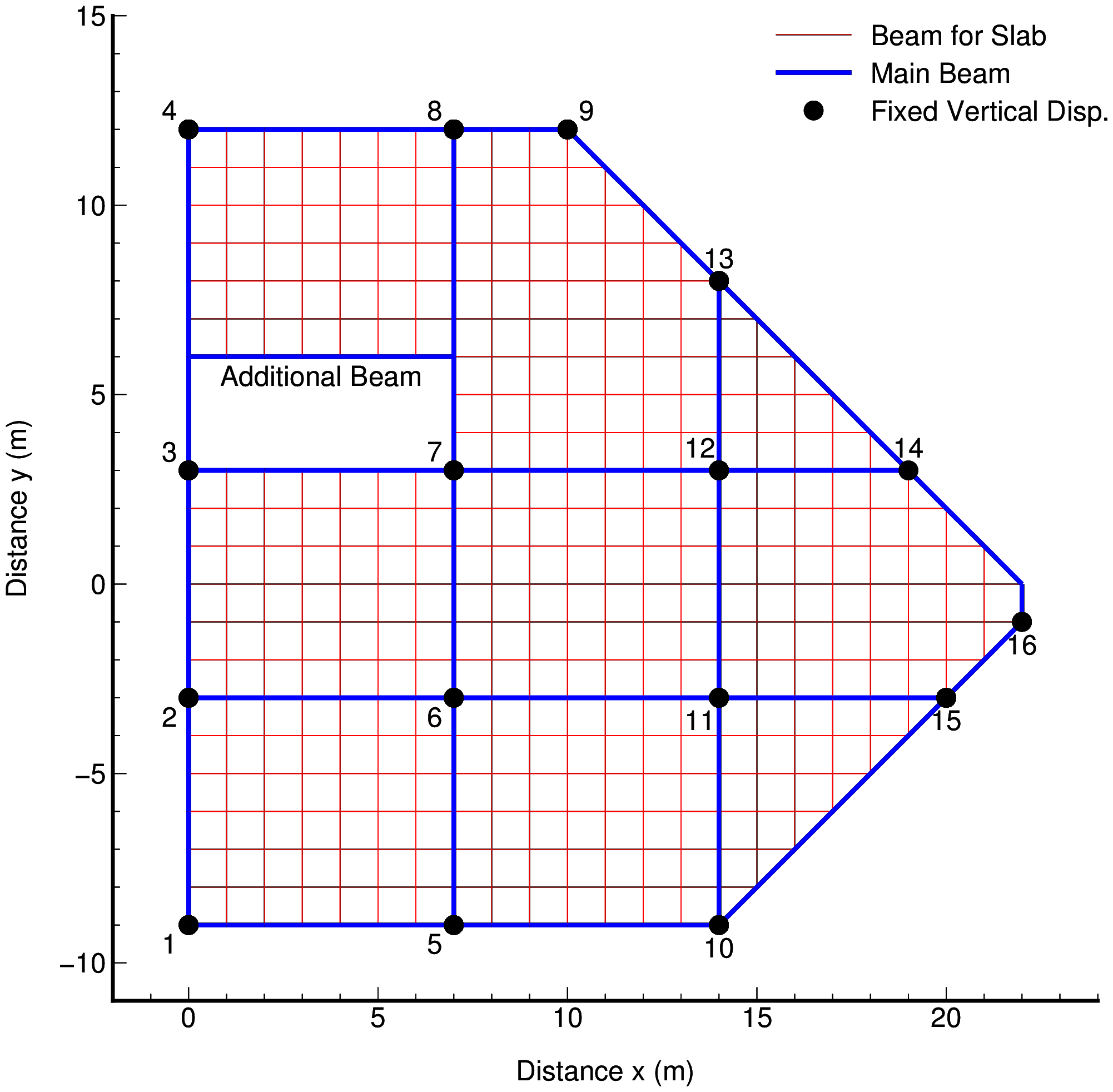

A model which is pentagon shape grid girder system made by RC is subjected to the vertical distributed loads.

6.3 Execution command for FEM analysis and drawing

python3 py_fem_grid.py inp_grid.txt out_grid.txt # FEM calculation

python3 py_grid_result.py out_grid.txt # Data making for GMT drawings

bash a_gmt_result.txt # GMT script for drawing

(Reference) ImageMagick command for format change from eps to png

mogrify -trim -density 300 -bordercolor "#ffffff" -border 10x10 -format png *.eps

rm *.eps

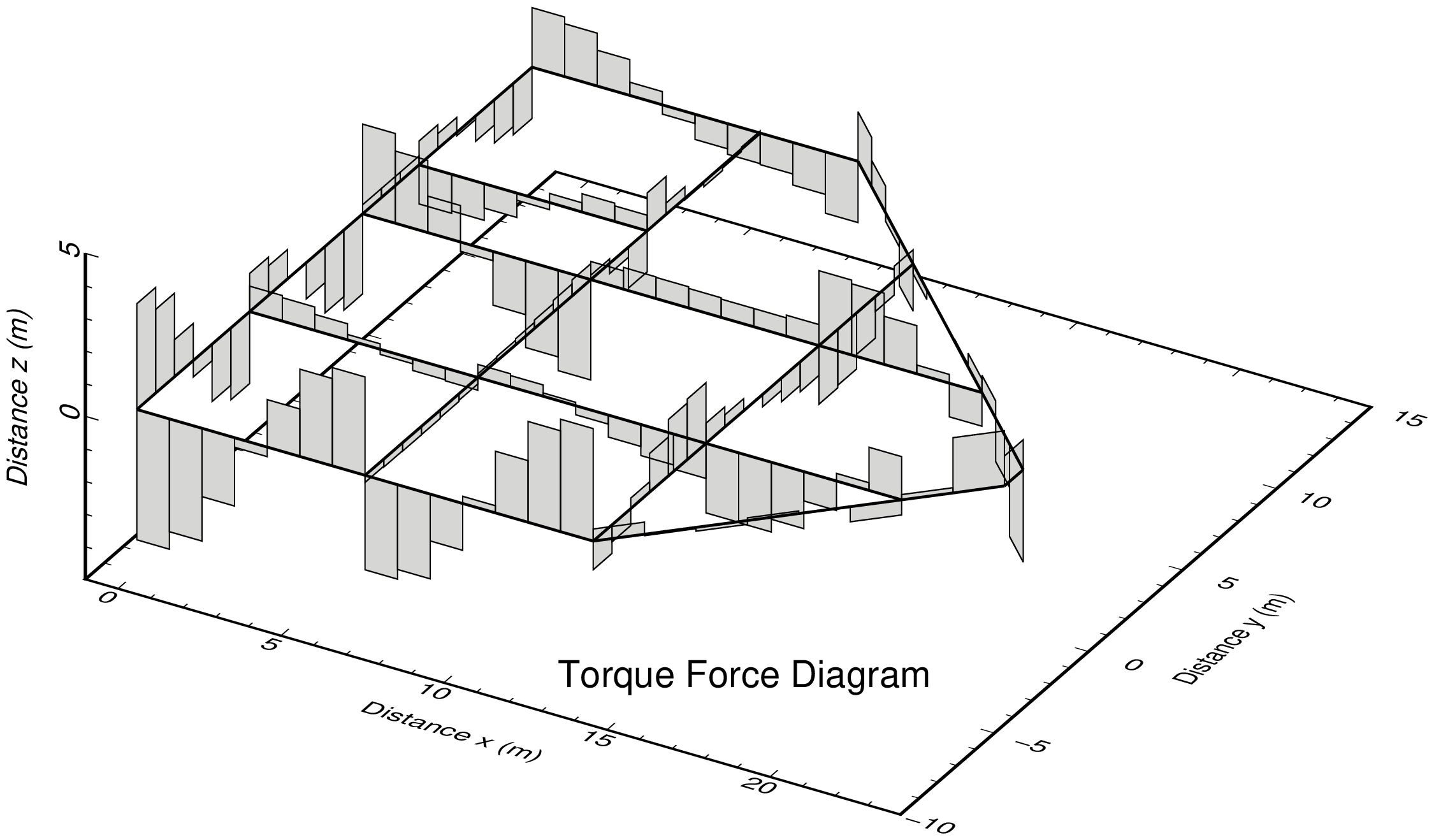

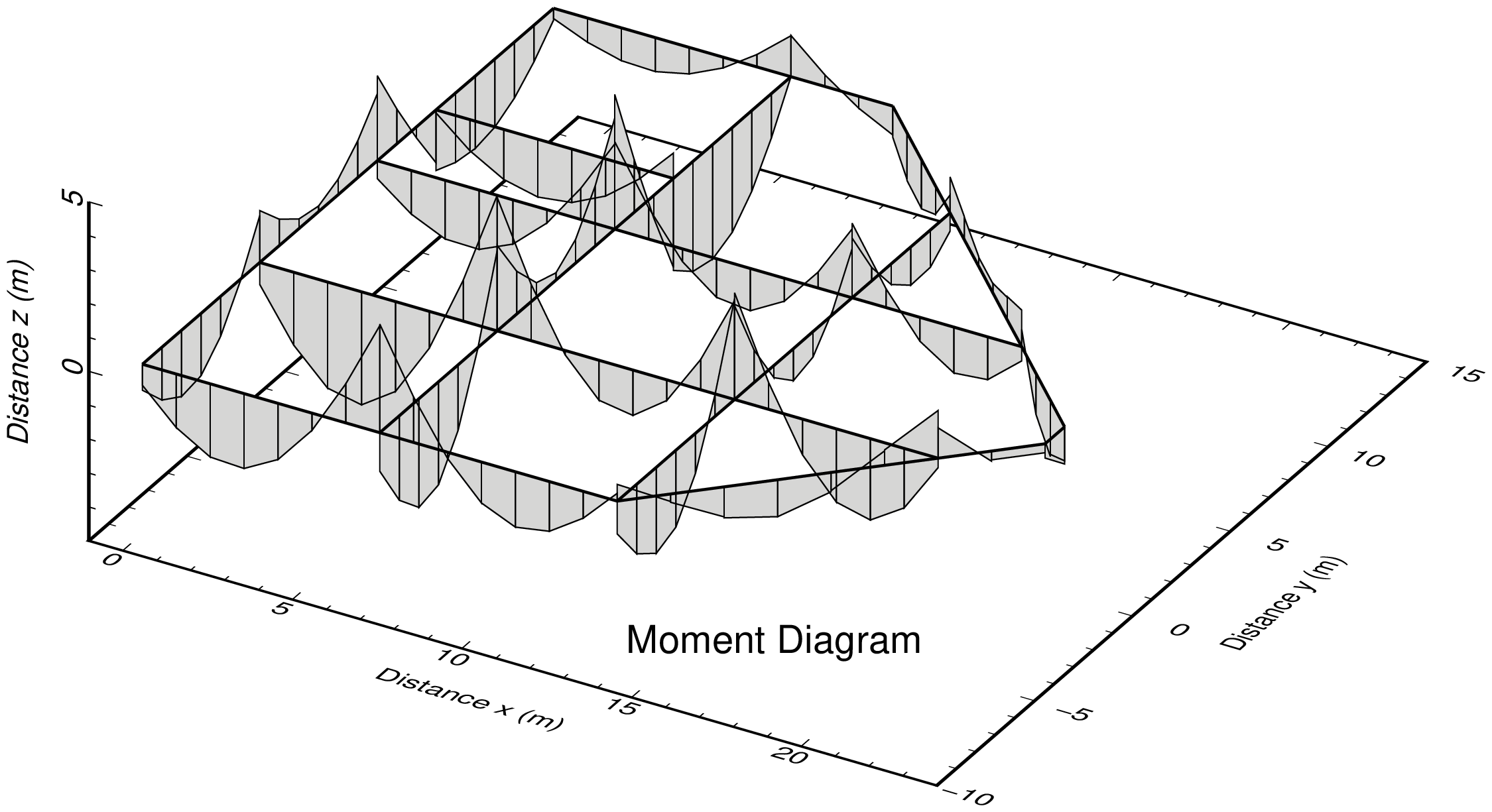

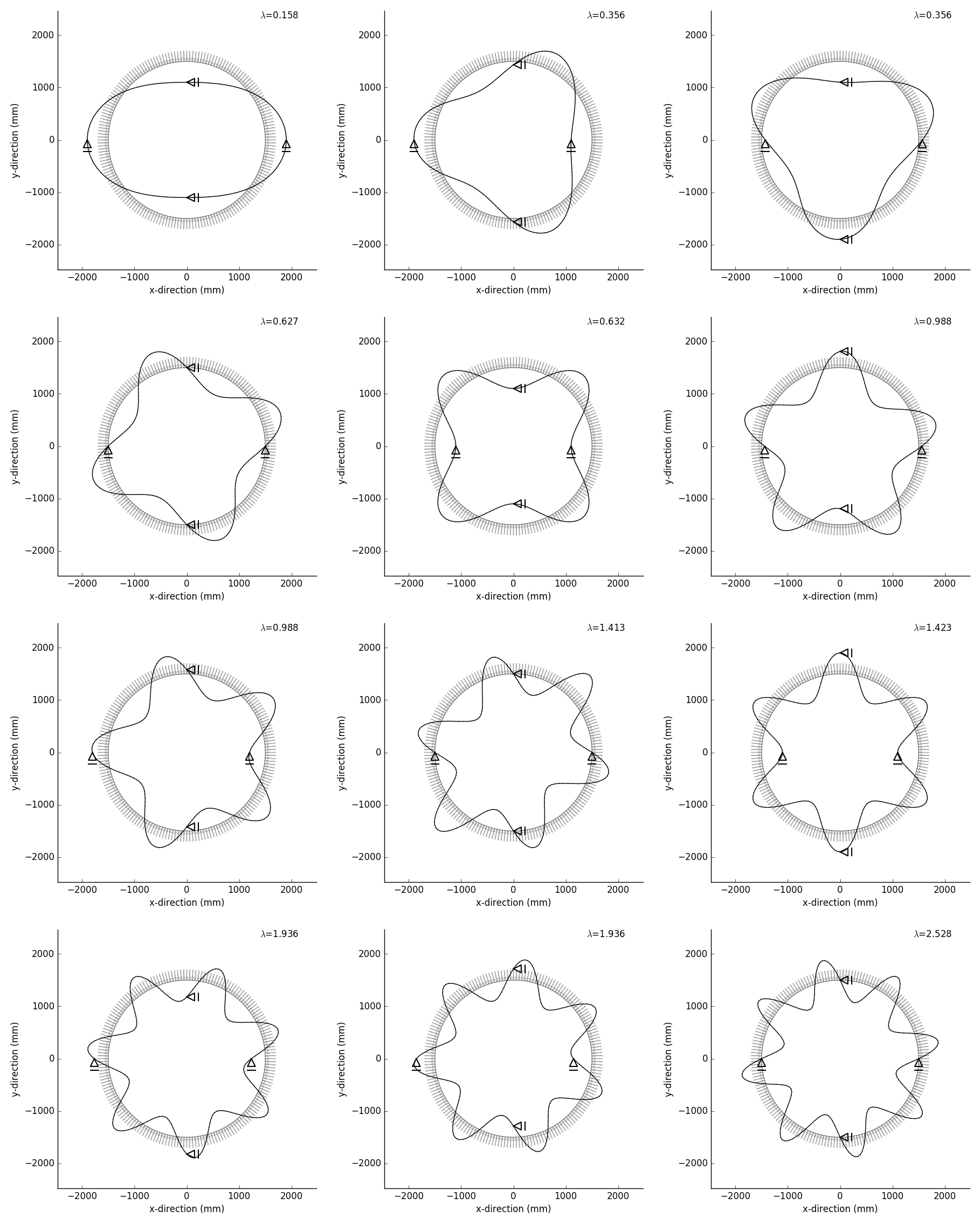

6.4 Sample drawings

(1) Drawings of analysis model and loading pattern by GMT

Python program 'py_grid_model.py' and shell script including GMT command 'a_gmt_model.txt' were used for these works.

eps images by GMT were converted to png images by ImageMagick.

|

|

| Analysis model of grid girder system | Loading pattern (vertical load) |

|---|

(2) Section force diagrams by GMT

Python program 'py_grid_result.py' and shell script including GMT command 'a_gmt_result.txt' were used for these works.

eps images by GMT were converted to png images by ImageMagick.

3D Frame Analysis

1. Outline

- This is a program for 3D frame analysis. Elastic and small displacement problems can be treated.

- Beam element with 2 nodes is used. 1 node has 6 degrees of freedom in X-Y-Z direction displacements and rotations around X-Y-Z axes.

- Nodal external force, nodal forced displacement, nodal temperature change and inertia force for element can be given as loads.

- In the global coordinate system, Z axis is defined as a vertical axis and X and Y axes are defined as a horizontal plane.

- In the local coordinate system, x axis is defined as the member axis direction and y and z axes are defined as principal axes of a section.

- Simultaneous linear equations are solved using numpy.linalg.solve(A, b).

- Input/Output file name can be defined arbitrarily with the format of space separater and those are inputted as command line arguments of a terminal.

| Valid boundary conditions |

|---|

| Item | Description |

|---|

| External force | Specify the loded nodes and load values |

| Temperature change | Specify the temperature change at all nodes |

| Inertia force | Specify the inertia force as a ratio to the gravity acceleration in X, Y and Z directions in the material properties data |

| Forced displacement | Specify the nodes with forced displacements and those values. Any values can be applied including zero |

2. FEM program

3. Command format for FEM analysis execution

python3 py_fem_3dfrm.py inp.txt out.txt

| inp.txt | : Input data file (separated by space) |

| out.txt | : Output data file (separated by space) |

4. Input data format

npoin nele nsec npfix nlod # Basic values for analysis

E po A Ix Iy Iz theta alpha gamma gkX gkY gkZ

..... (1 to nsec) ..... # Material properties

node_1 node_2 isec # Element connectivity, material set number

..... (1 to nele) ..... #

x y z deltaT # Node coordinate, temperature change of node

..... (1 to npoin) ..... #

lp kox koy koz kmx kmy kmz rdis_x rdis_y rdis_z rrot_x rrot_y rrot_z

..... (1 to npfix) ..... # Restricted node and restrict conditions

lp fp_x fp_y fp_z mp_x mp_y mp_z # Loaded node and loading conditions

..... (1 to nlod) ..... # (omit data input if nlod=0)

npoin, nele, nsec : number of nodes, number of elements, number of material sets

npfix, nlod : number of restricted nodes, number of loaded nodes

E, po, A : elastic modulus, Poisson's ratio, section area

Ix, Iy, Iz, theta : torsional constant, moment of inertia around y-axis or z-axis, chord angle

alpha, gamma : thermal expansion coefficient, unit weight of material

gkX, gkY, gkZ : accelerations in X, Y and Z directions (ratio to 'g')

node-1, node-2, isec : node-1, node-2, material set number

x, y, z, deltaT : (x,y,z) coordinate of node, nodal temperature change

lp,kox,koy,koz : node, kind of displacement restriction in X, Y and Z directions (0: free, 1: fixed)

kmx,kmy,kmz : kind of rotation restriction around X, Y and Z axis (0: free, 1: fixed)

rdis_x,rdis_y,rdis_z : forced displacements in X, Y and Z direction (input zero iven if no-restriction)

rrot_x,rrot_y,rrot_z : forced rotations around X, Y and Z axis (input zero even if no-restriction)

lp, fp_x, fp_y, fp_z : loaded node, loads in X, Y amd Z direction

mp_x, mp_y, mp_z : moments around X, Y and Z axis

5. Output data format

npoin nele nsec npfix nlod

(Each value of above)

sec E po A J Iy Iz theta

sec alpha gamma gkX gkY gkZ

sec : Material number

E : Elastic modulus

po : Poisson's ratio

A : Section area

J ; Torsional constant

Iy : Moment of inertia around y-axis

Iz : Moment of inertia around z-axis

theta : Chord angle

alpha : Thermal expansion coefficient

gamma : Unit weight

gkX : Acceleration in X-direction (ratio to g)

gkY : Acceleration in Y-direction (ratio to g)

gkZ : Acceleration in Z-direction (ratio to g)

..... (1 to nsec) .....

node x y z fx fy fz mx my mz deltaT

node : Node number

x : x-coordinate

y : y-coordinate

fx : Load in X-direction

fy : Load in Y-direction

fz : Load in Z-direction

mx : Moment load around X-axis

my : Moment load around Y-axis

mz : Moment load around Z-axis

deltaT : Temperature change of node

..... (1 to npoin) .....

node kox koy koz kmx kmy kmz rdis_x rdis_y rdis_z rrot_x rrot_y rrot_z

node : Node number

kox : Index of restriction in X-direction (0: free, 1: fixed)

koy : Index of restriction in Y-direction (0: free, 1: fixed)

koz : Index of restriction in Z-direction (0: free, 1: fixed)

kmx : Index of restriction in rotation around X-axis (0: free, 1: fixed)

kmy : Index of restriction in rotation around Y-axis (0: free, 1: fixed)

kmz : Index of restriction in rotation around Z-axis (0: free, 1: fixed)

rdis_x : Given displacement in X-direction

rdis_y : Given displacement in Y-direction

rdis_z : Given displacement in Z-direction

rrot_x : Given displacement in rotation around X-axis

rrot_y : Given displacement in rotation around Y-axis

rrot_z : Given displacement in rotation around Z-axis

..... (1 to npfix) .....

elem i j sec

elem : Element number

i : Node number of start point

j : Node number of end point

sec : Material number

..... (1 to nele) .....

node dis-x dis-y dis-z rot-x rot-y rot-z

node : Node number

dis-x : Displacement in X-direction

dis-y : Displacement in Y-direction

dis-z : Displacement in Z-direction

rot-x : Rotation around X-axis

rot-y : Rotation around Y-axis

rot-z : Rotation around Z-axis

..... (1 to npoin) .....

elem nodei N_i Sy_i Sz_i Mx_i My_i Mz_i

elem nodej N_j Sy_j Sz_j Mx_j My_j Mz_j

elem : Element number

nodei : First node nymber

nodej : Second node number

N_i : Axial force of node-i

Sy_i : Shear force of node-i in y-direction

Sz_i : Shear force of node-i in z-direction

Mx_i : Moment of node-i around x-axis (torsional moment)

My_i : Moment of node-i around y-axis (bending moment)

Mz_i : Moment of node-i around z-axis (bending moment)

N_j : Axial force of node-j

Sy_j : Shear force of node-j in y-direction

Sz_j : Shear force of node-j in z-direction

Mx_j : Moment of node-j around x-axis (torsional moment)

My_j : Moment of node-j around y-axis (bending moment)

Mz_j : Moment of node-j around z-axis (bending moment)

..... (1 to nele) .....

n=(total degrees of freedom) time=(calculation time)

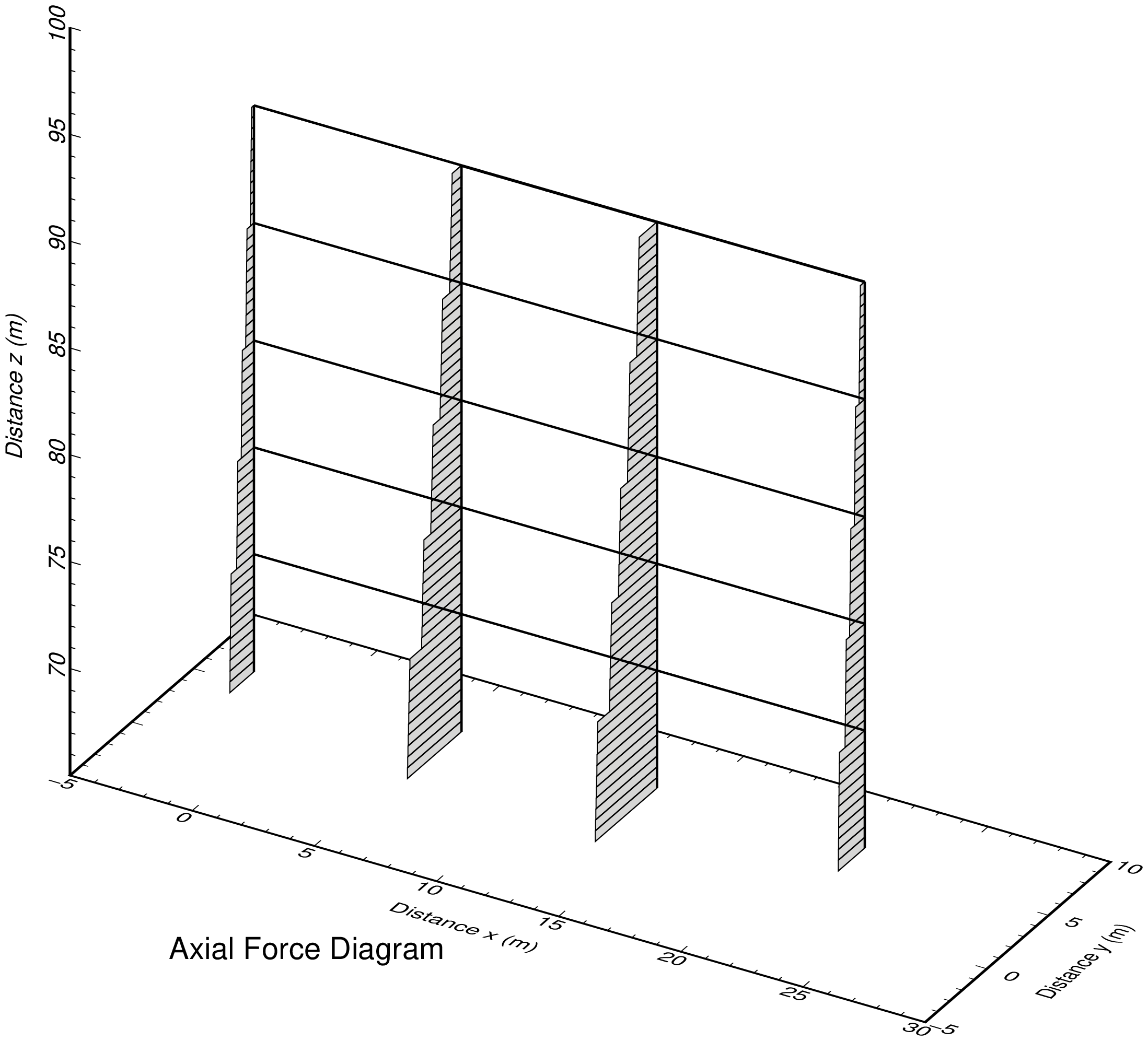

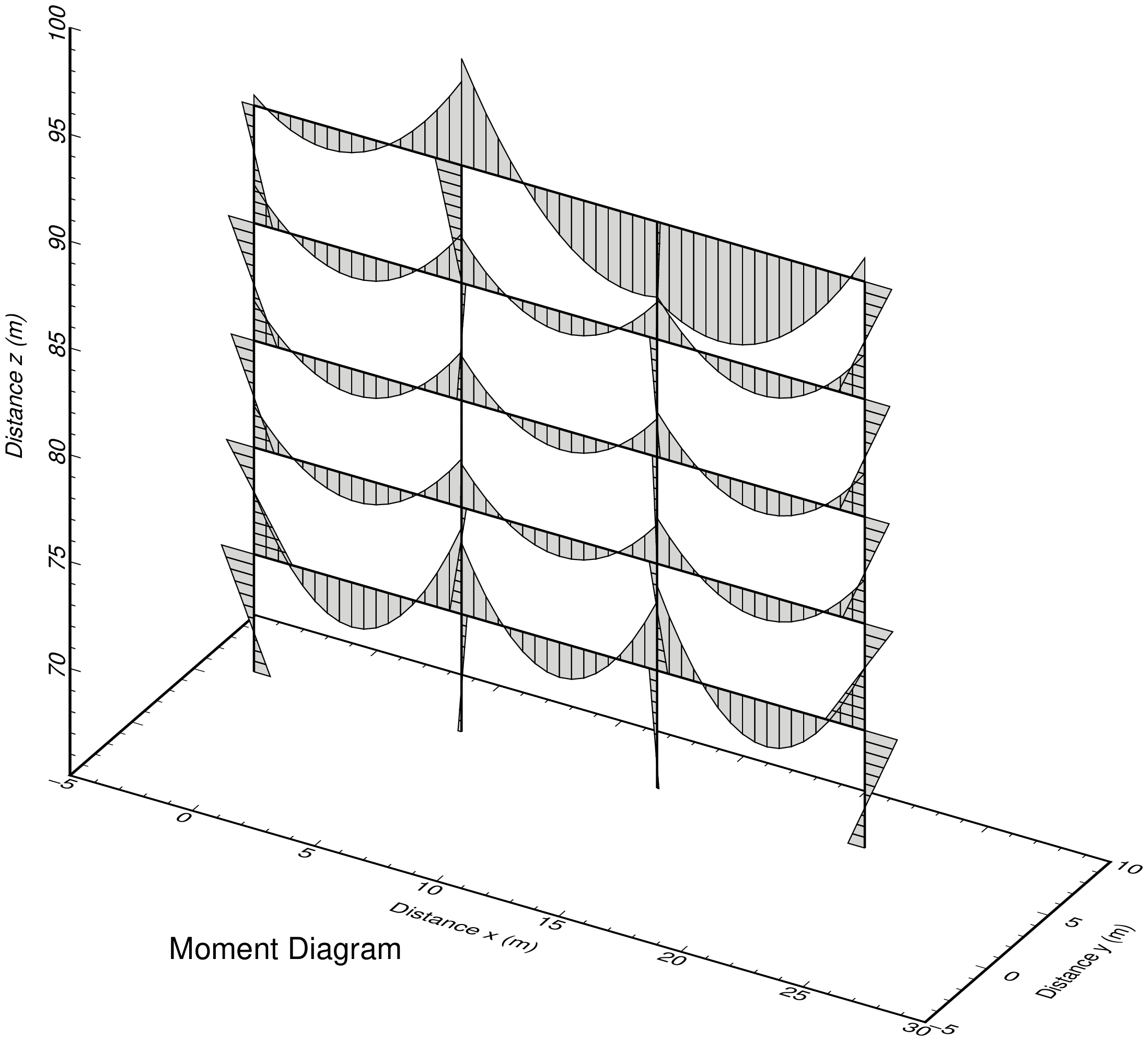

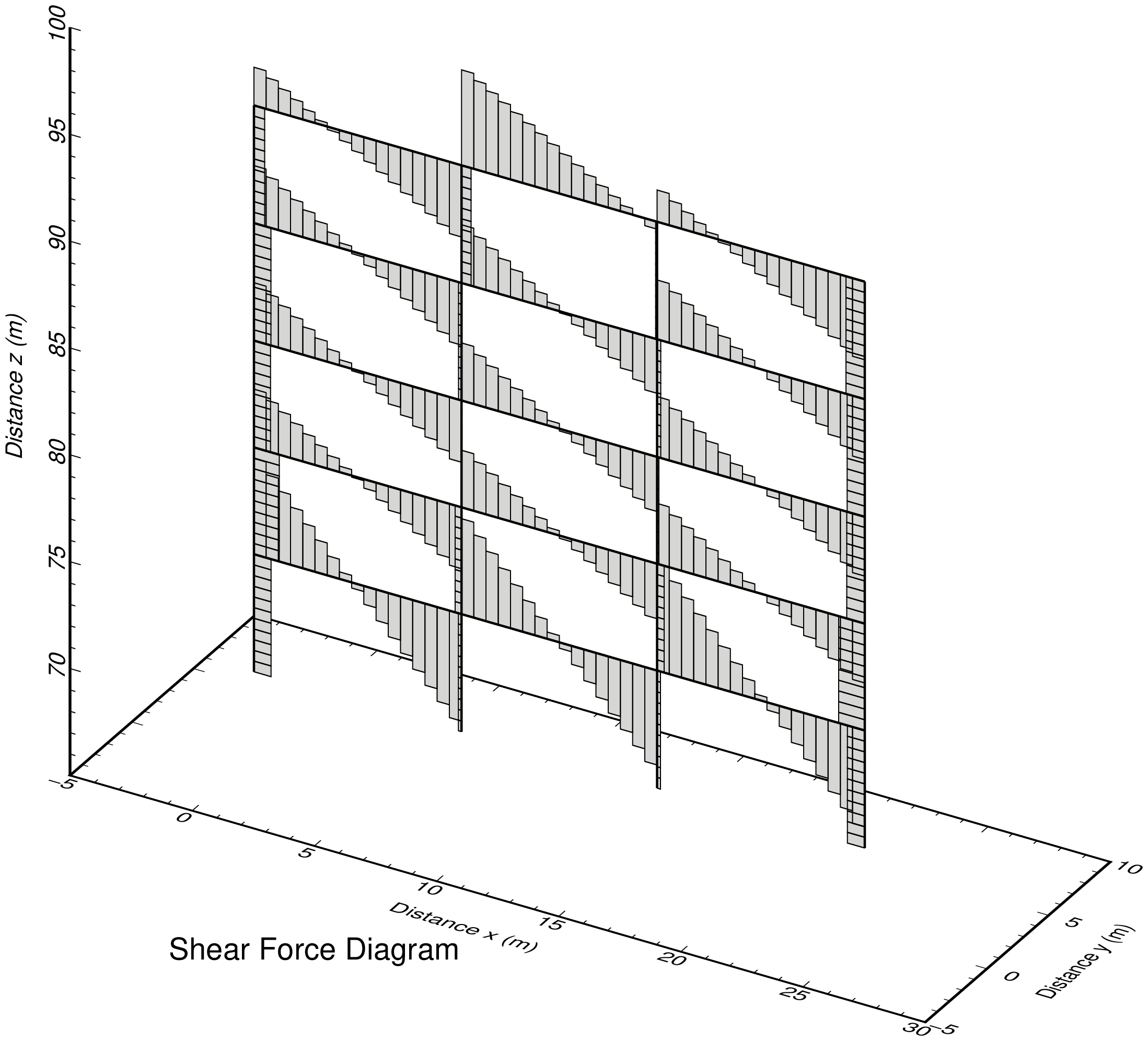

6. Output samples

6.1 Control script

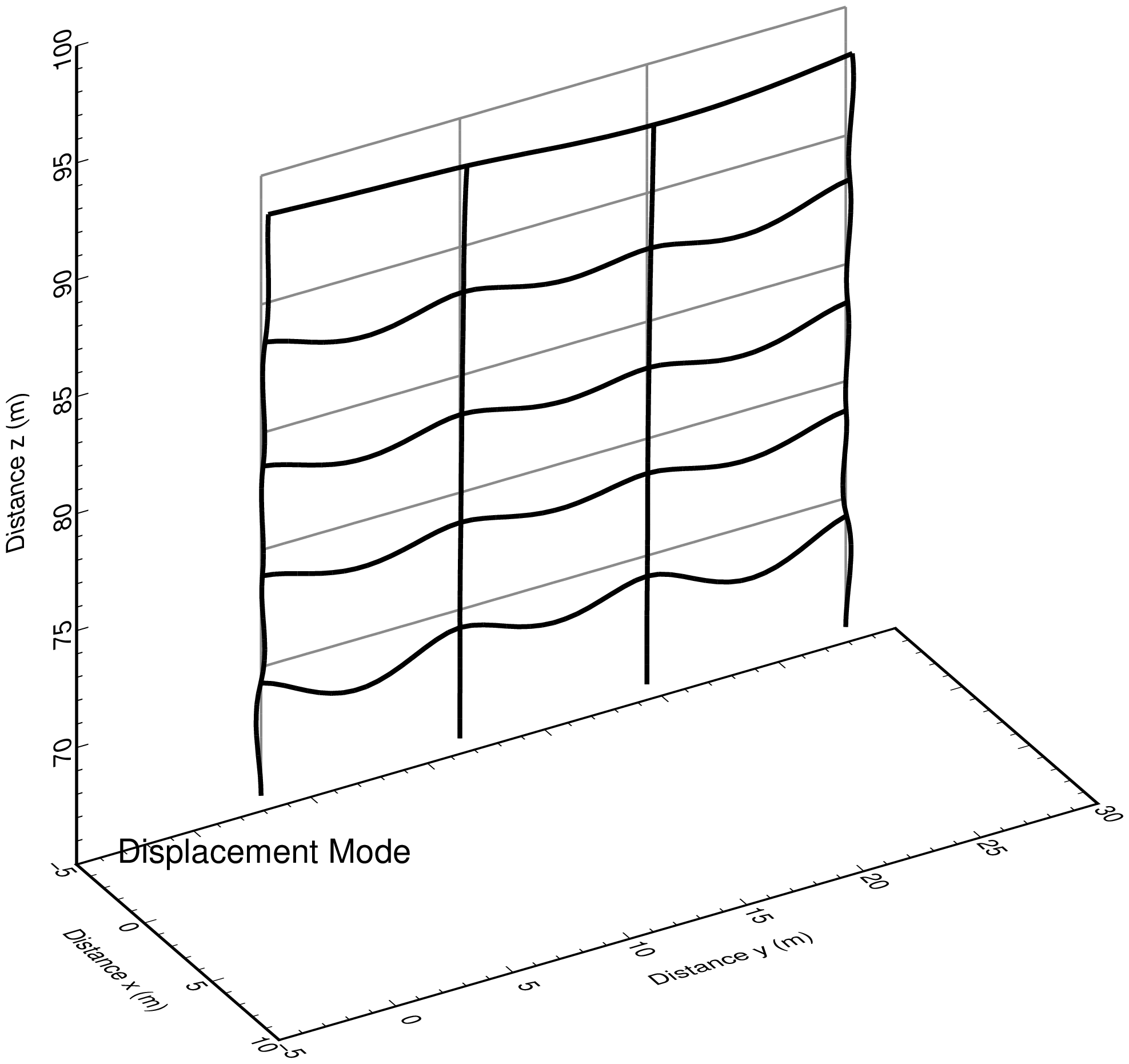

python3 py_fem_3dfrm.py inp_3dfrm_grid.txt out_3dfrm_grid.txt

python3 py_fig_3dfrm_grid.py

source a_3dfrm_grid.txt

python3 py_fem_3dfrm.py inp_3dfrm_b3_yz.txt out_3dfrm_b3_yz.txt

python3 py_fig_3dfrm_cpost1.py

source a_3dfrm_cpost1.txt

python3 py_fem_3dfrm.py inp_3dfrm_b3_xz.txt out_3dfrm_b3_xz.txt

python3 py_fig_3dfrm_cpost2.py

source a_3dfrm_cpost2.txt

rm _*

6.2 Input data samples and auxiliary programs

Samples of section force diagrams

Input data file:inp_3dfrm_grid.txt

Input data file:inp_3dfrm_b3_yz.txt

Input data file:inp_3dfrm_b3_xz.txt

2D Stress Analysis

1. Outline

- This is a program for 2D stress analysis including plane strain and plane stress state problem based on elastic and small displacement theorem with isotropic material.

- 4 node isoparametric element with 4 Gauss points is used as a 4 node element. 1 node has 2 degrees of freedom in horizontal direction and vertical direction.

- Nodal external force, nodal forced displacement, nodal temperature change and inertia force for element can be given as loads.

- In coordinate system, x-direction is defined as right-direction, y-direction is defined as upward direction.

- Simultaneous linear equations are solved using numpy.linalg.solve(A, b).

- Input/Output file name can be defined arbitrarily with the format of space separater and those are inputted as command line arguments of a terminal.

| Valid boundary conditions |

|---|

| Item | Description |

|---|

| External force | Specify the loded nodes and load values |

| Temperature change | Specify the temperature change at all nodes |

| Inertia force | Specify the inertia force as a ratio to the gravity acceleration in horizontal and vertical direction in the material properties data |

| Forced displacement | Specify the nodes with forced displacements and those values. Any values can be applied including zero |

2. FEM program

3. Command format for FEM analysis execution

python3 py_fem_pl4.py inp.txt out.txt

| inp.txt | : Input data file (separated by space) |

| out.txt | : Output data file (separated by space) |

4. Input data format

npoin nele nsec npfix nlod NSTR # Basic values for analysis

t E po alpha gamma gkh gkv # Material properties

..... (1 to nsec) ..... #

node1 node2 node3 node4 isec # Element connectivity, material set number

..... (1 to nele) ..... # (counter-clockwise order of node number)

x y deltaT # Coordinate, Temperature change of node

..... (1 to npoin) ..... #

node kox koy rdisx rdisy # Restricted node and restrict conditions

..... (1 to npfix) ..... #

node fx fy # Loaded node and loading conditions

..... (1 to nlod) ..... # (omit data input if nlod=0)

| npoin, nele, nsec | : number of nodes, number of elements, number of material sets |

| npfix, nlod | : number of restricted nodes, number of loaded nodes |

| NSTR | : Stress state (0: plane strain, 1: plane stress) |

| t, E, po, alpha | : element thickness, elastic modulus, Poisson's ratio, thermal expansion coefficient |

| gamma, gkh, gkv | : unot weight, horizontal and vertical acceleration (ratio to 'g') |

| node1, node2, node3, node4, isec | : node1, node2, node3, node4, material set number |

| x, y, deltaT | : x-coordinate, y-coordinate, nodal temperature change |

| node, kox, koy | : node, kind of restriction in x and y direction (0: free, 1: fixed) |

| rdisx, rdisy | : forced displacements in x and y-directions (input zero even if no-restriction) |

| node, fx, fy | : loaded node, load in x and y-direction |

5. Output data format

npoin nele nsec npfix nlod NSTR

(Each value of above)

sec t E po alpha gamma gkh gkv

sec : Material number

t : Element thickness

E : Elastic modulus

po : Poisson's ratio

alpha : Thermal expansion coefficient

gamma : Unit weight

gkh : Acceleration in x-direction (ratio to g)

gkv : Acceleration in y-direction (ratio to g)

..... (1 to nsec) .....

node x y fx fy deltaT kox koy

node : Node number

x : x-coordinate

y : y-coordinate

fx : Load in x-direction

fy : Load in y-direction

deltaT : Temperature change of node

kox : Index of restriction in x-direction (0: free, 1: fixed)

koy : Index of restriction in x-direction (0: free, 1: fixed)

..... (1 to npoin) .....

node kox koy rdis_x rdis_y

node : Node number

kox : Index of restriction in x-direction (0: free, 1: fixed)

koy : Index of restriction in y-direction (0: free, 1: fixed)

rdis_x : Given displacement in x-direction

tdis_y : Given displacement in y-direction

..... (1 to npfix) .....

elem i j k l sec

elem : Element number

i : Node number of start point

j : Node number of second point

k : Node number of third point

l : Node number of end point

sec : Material number

..... (1 to nele) .....

node dis-x dis-y

node : Node number

dis-x : Displacement in x-direction

dis-y : Displacement in y-direction

..... (1 to npoin) .....

elem sig_x sig_y tau_xy p1 p2 ang

elem : Element number

sig_x : Normal stress in x-direction

sig_y : Normal stress in y-direction

tau_xy : Shear stress in x-y plane

p1 : First principal stress

p2 : Second principal stress

ang : Angle of the first principal stress

..... (1 to nele) .....

n=(total degrees of freedom) time=(calculation time)

| dis-x, dis-y | : displacements in x and y-directions |

| sig_x, sig_y, tau_xy | : normal stresses in x and y-direction, shearing stress |

| p1, p2, ang | : !st principal stress, 2nd principal stress, angle of 1st principal stress |

| n | : Total degrees of freedom (the number of the variables) |

| time | : Calculation time |

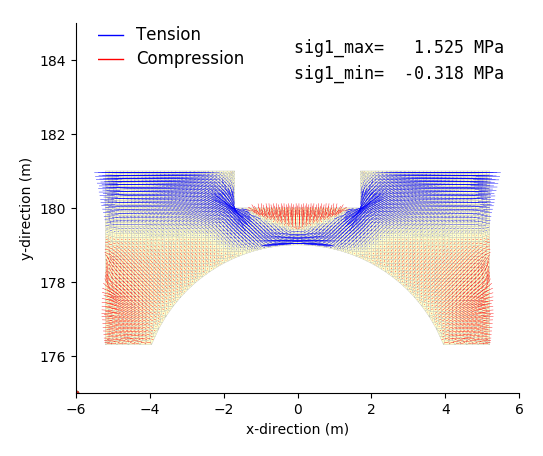

6. Output sample

6.1 Input data sample and auxiliary program

6.2 Outline of sample analysis model

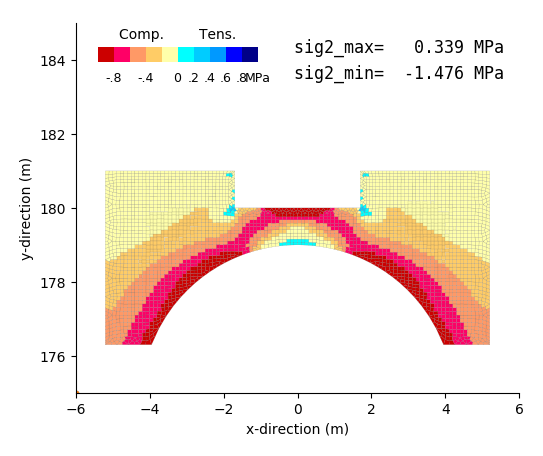

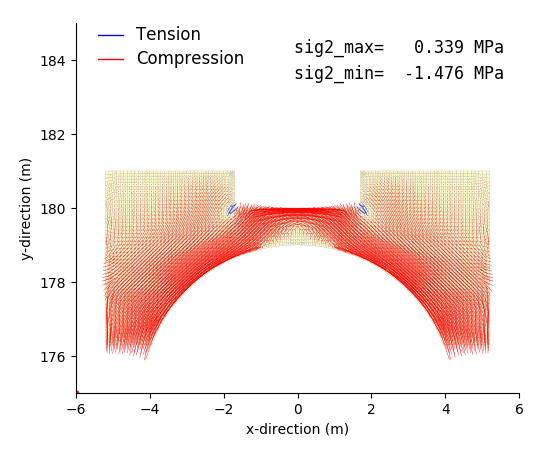

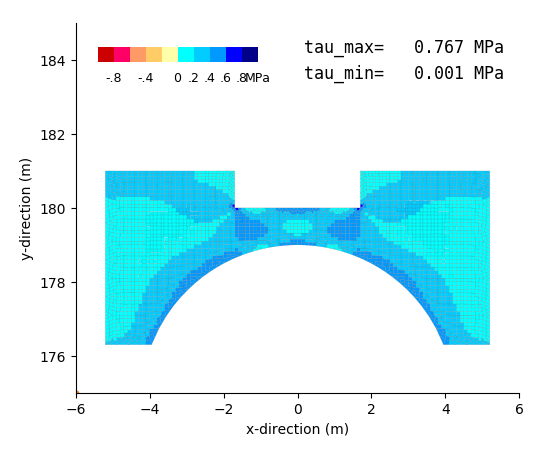

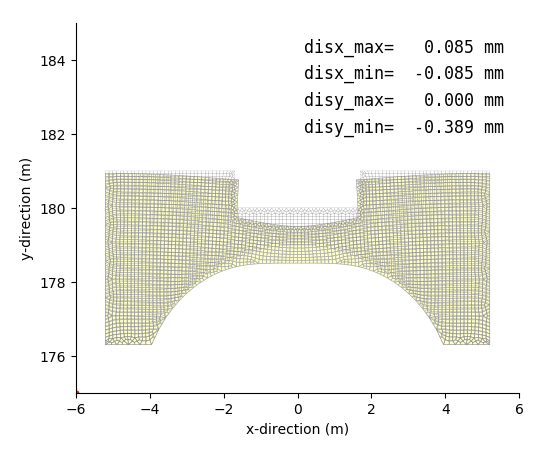

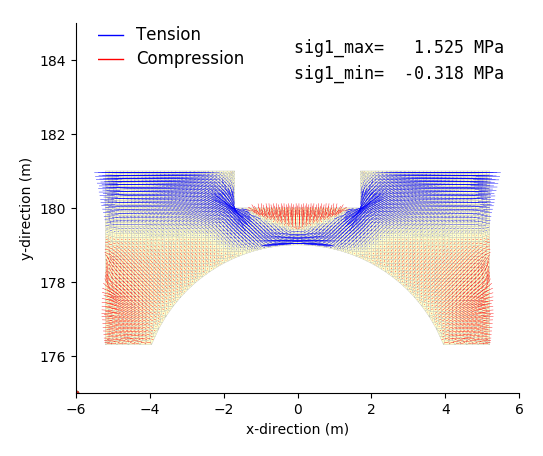

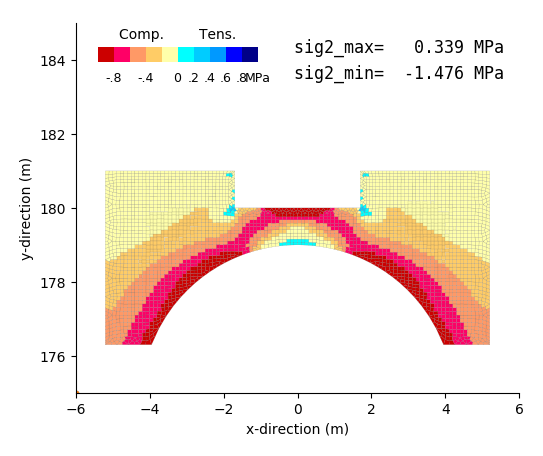

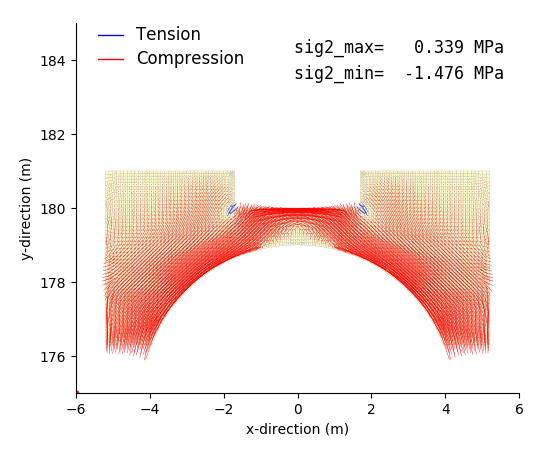

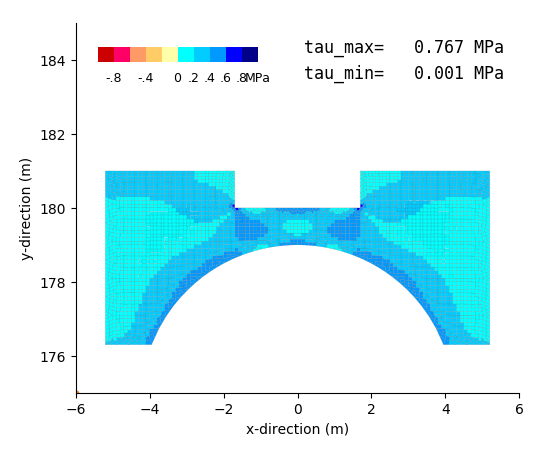

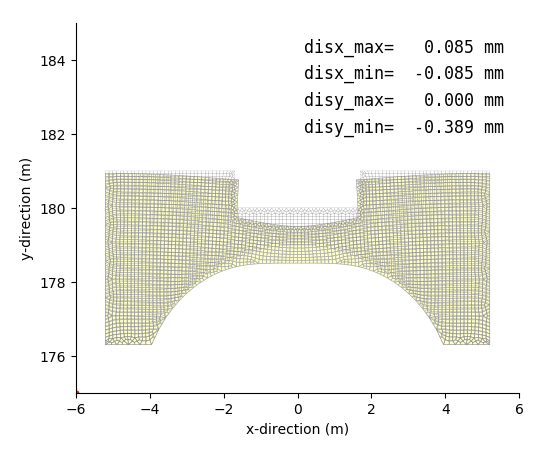

Model is an RC arch with wide notch at center of the arch. The loads subjected are vertical distributed load on wide notch and self weight of the concrete.

6.3 Execution command for FEM analysis and drawing

python3 py_fem_pl4.py inp_arch.txt out_arch.txt

python3 py_fig_cont_pl4.py out_arch.txt

python3 py_fig_vect_pl4.py out_arch.txt

| out_arch.txt | : output data file by FEM analysis (separated by space) |

The drawing programs create following images automatically.

py_fig_cont.py

| _fig_pl4_con1.png | : 1st principal stress color contour |

| _fig_pl4_con2.png | : 2nd principal stress color contour |

| _fig_pl4_con3.png | : maximum shearing stress color contour |

py_fig_vect.py

| _fig_pl4_disp.png | : displacement mode diagram |

| _fig_pl4_vec1.png | : 1st principal stress vector diagram |

| _fig_pl4_vec2.png | : 2nd principal stress vector diagram |

In these programs, drawing range, clasification of stress value and its color, drawing scales of displacement and stress values shall be rewriten properly considering the analysis results.

6.4 Sample drawings

png image drawings which were established by programs 'py_fig_cont_pl4.py' and 'py_fig_vect_pl4.py' are shown below.

|

|

| First principal stress contour | First principal stress vector |

|---|

|

|

| Second principal stress contour | Second principal stress vector |

|---|

|

|

| Maximum shearing stress contour | Disolacement mode |

|---|

Axisymmetric Stress Analysis

1. Outline

- This is a program for qxisymmetric stress analysis based on elastic and small displacement theorem with isotropic material.

- 4 node isoparametric element with 4 Gauss points is used as a 4 node element. 1 node has 2 degrees of freedom in rotation axial direction and radial direction.

- Thickness of circumference direction of 1 element is 1 radian.

- Nodal external force, nodal forced displacement, nodal temperature change and inertia force for element in only rotation axis direction can be given as loads.

- In coordinate system, z-direction is defined as rotation axis direction, r-direction is defined as radial direction.

- Simultaneous linear equations are solved using numpy.linalg.solve(A, b).

- Input/Output file name can be defined arbitrarily with the format of space separater and those are inputted as command line arguments of a terminal.

| Valid boundary conditions |

|---|

| Item | Description |

|---|

| External force | Specify the loded nodes and load values |

| Temperature change | Specify the temperature change at all nodes |

| Inertia force | Specify the inertia force as a ratio to the gravity acceleration in horizontal and vertical direction in the material properties data |

| Forced displacement | Specify the nodes with forced displacements and those values. Any values can be applied including zero |

2. FEM program

3. Command format for FEM analysis execution

python3 py_fem_asnt.py inp.txt out.txt

| inp.txt | : Input data file (separated by space) |

| out.txt | : Output file name (separated by space) |

4. Input data format

npoin nele nsec npfix nlod # Basic values for analysis

E po alpha gamma gkz # Material properties

..... (1 to nsec) ..... #

node1 node2 node3 node4 isec # Element connectivity, material set number

..... (1 to nele) ..... # (counter-clockwise order of node number)

z r deltaT # Coorinate, temperature change of node

..... (1 to npoin) ..... #

node koz kor rdisz rdisr # Restricted node and restrict conditions

..... (1 to npfix) ..... # (omit data input if npfix=0)

node fz fr # Loaded node and loading conditions

..... (1 to nlod) ..... # (omit data input if nlod=0)

| npoin, nele, nsec | : number of nodes, number of elements, number of material sets |

| npfix, nlod | : number of restricted nodes, number of loaded nodes |

| E, po, alpha | : elastic modulus, Poisson's ratio, thermal expansion coefficient |

| gamma, gkz | : unot weight, acceleration in rotation axis direction (ratio to 'g') |

| node1, node2, node3, node4, isec | : node1, node2, node3, node4, material set number |

| z, r, deltaT | : z-coordinate, r-coordinate, nodal temperature change |

| node, koz, kor | : node, kind of restriction in z and r direction (0: free, 1: fixed) |

| rdisz, rdisr | : forced displacements in z and r-directions (input zero even if no-restriction) |

| node, fz, fr | : loaded node, load in z and r-direction |

Explanation of load input method

A cylinder under the internal pressure is considered. The cylinder has the radius of r=3000mm, the length in rotation axial direction of z=200mm and internal pressure of p=1 N/mm2 is acted. Total load acted to 1 element with thickness of 1 radian is shown below.

\begin{align}

&p \times r \times 1 (rad) \times z \\

&= 1 (n/mm^2) \times 3,000 (mm) \times 1 (rad) \times 200 (mm) \\

&= 600,000 (N)

\end{align}

So, below loads must be acted for each node according to the thinking of equivalent nodal force,

| Item | Details |

|---|

| Nodal force | 300,000(N) | 300,000(N) |

| Coordinate of node | (z,r)=(0,3,000) | (z,r)=(200,3,000) |

| Direction of load | Positive radius direction | Positive radius direction |

5. Output data format

npoin nele nsec npfix nlod

(Each value of above)

sec E po alpha gamma gkz

sec : Material number

E : Elastic modulus

po : Poisson's ratio

alpha : Thermal expansion coefficient

gamma : Unit weight

gkz : Acceleration in rotation axis direction (ratio to g)

..... (1 to nsec) .....

node z r fz fr deltaT koz kor

node : Node number

z : z-coordinate (rotation axis direction)

r : r-coordimate (radial direction)

fz : Load in z-direction

fr : Load in r-direction

deltaT : Temperature change of node

koz : Index of restriction in z-direction (0: free, 1: fixed)

kor : Index of restriction in r-direction (0: free, 1: fixed)

..... (1 to npoin) .....

node koz kor rdis_z rdis_r

node :

koz : Index of restriction in z-direction (0: free, 1: fixed)

kor : Index of restriction in r-direction (0: free, 1: fixed)

rdis_z : Given displacement in z-direction

rdis_r : Given displacement in r-direction

..... (1 to npfix) .....

elem i j k l sec

elem : Element number

i : Node number of start point

j : Node number of second point

k : Node number of third point

l : Node number of end point

sec : Material number

..... (1 to nele) .....

node dis-z dis-r

node : Node number

dis-z : Displacement in z-direction

dis-r : Displacement in r-direction

..... (1 to npoin) .....

elem sig_z sig_r sig_t tau_zr p1 p2 ang

elem : Element number

sig_z : Normal stress in z-direction

sig_r : Normal stress in r-direction

sig_t : Normal stress in rotation (Third principal stress)

tau_zr : Shear stress in z-r plane

p1 : First principal stress in z-r plane

p2 : Second principal stress in z-r plane

ang : Angle of the first principal stress in z-r plane

..... (1 to nele) .....

n=(total degrees of freedom) time=(calculation time)

| dis-z, dis-r | : displacements in z and r directions |

| sig_z, sig_r | : normal stress in z and r directions |

| sig_t | : normal stress in circumference direction to rotation axis (3rd principal stress) |

| p1, p2, ang | : 1st and 2nd principal stresses in z-r plane, angle of 1st principal stress |

| n | : Total degrees of freedom (the number of the variables) |

| time | : Calculation time |

6. Output sample (stress analysis of torus under internal water pressure)

6.1 Input data sample and auxiliary program

6.2 Execution command for FEM analysis and drawing

python3 py_fem_asnt.py inp_torus.txt out_torus.txt

python3 py_fig_data.py out_torus.txt

bash a_gmt_gra.txt

| inp_torus.txt | : Input data file for FEM analysis (separated by space) |

| out_torus.txt | : Output data file by FEM analysis (separated by space) |

6.3 Theoritical solution of stress in torus

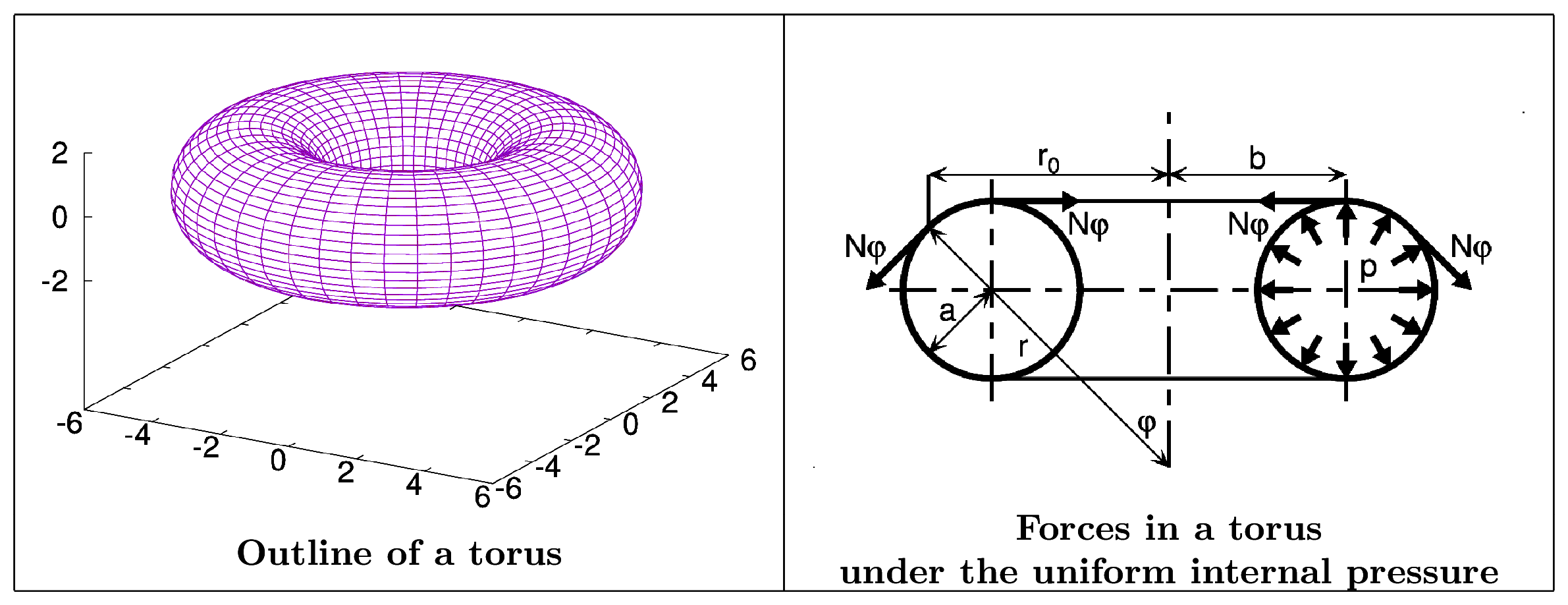

A torus shown below left drawing is explained in Wikipedia as following:

A torus is a surface of revolution generated by revolving a circle in three-dimensional space about an axis coplanar with the circle. If the axis of revolution does not touch the circle, the surface has a ring shape and is called a torus of revolution.

When a torus under the uniform internal water pressure is considered shown in above right drawing, the axial force $N_{\varphi}$ in circumferential direction of a circle with radius '$a$' and another axial force $N_{\theta}$ which is perpendicular to previus one are given in following equations which are described in 'Theory of Plates and Shells' by Timoshenko.

\begin{equation}

N_{\varphi}=\cfrac{p a (r_0 + b)}{2 r_0} \qquad\qquad N_{\theta}=\cfrac{p a}{2}

\end{equation}

From above, it can be understood that the value $N_{\varphi}$ is variable depending on the location although the value of $N_{\theta}$ is constant on the circle.

When the values of $N_{\varphi}$ are calculated at some representative points, folowings can be obtained.

\begin{align}

&N_{\varphi}=p a \left\{1 + \cfrac{a}{2(b - a)}\right\} & (r_0 = b - a) \\

&N_{\varphi}=p a & (r_0 = b) \\

&N_{\varphi}=p a \left\{1 - \cfrac{a}{2(b + a)}\right\} & (r_0 = b + a)

\end{align}

From above, the maximum force can be occurred at inside of circle ($r_0 = b - a$).

6.4 FEM Analysis

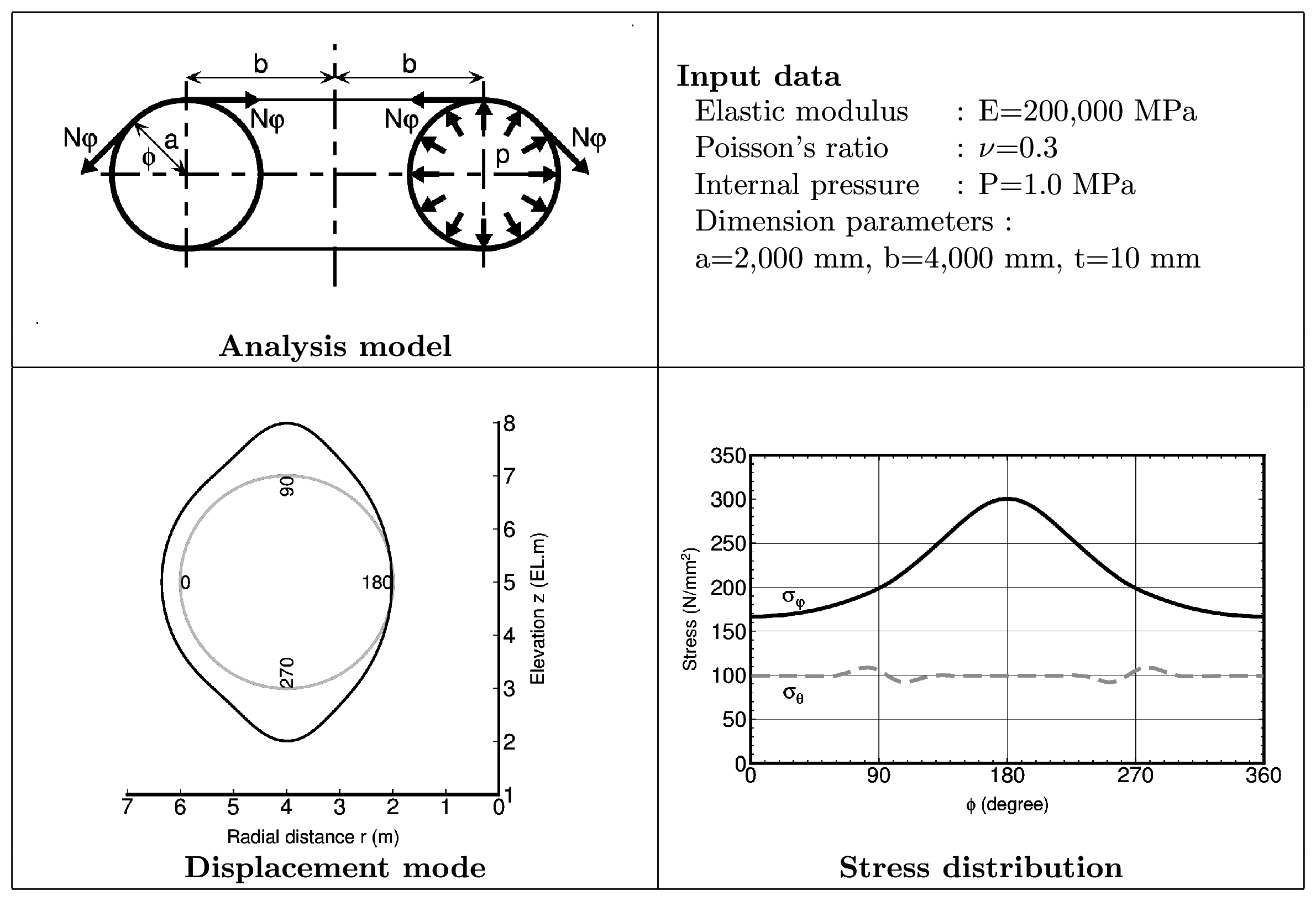

The results of an axisymmetric stress analysis using a program 'py_fem_asnt.py' are shown below.

Conditions of analysis

Elastic modulus

E (MPa) | Poisson's ratio

po | Internal pressure

p (MPa) | Radius

a (mm) | Radius

b (mm) | Material thickness

t (mm) |

|---|

| 200,000 | 0.3 | 1.0 | 2,000 | 4,000 | 10 |

| number of elements: 360 (center angle: 1 degree) |

The comparison of FEM analyis result and theoritical solution by Timoshenko is shown below.

| Location | FEM | Timoshenko |

|---|

| (φ) | σφ | σθ | σφ | σθ |

|---|

| 0 (r=b+a) | 166.59 | 99.54 | 166.66 | 100.00 |

| 90 (r=b) | 198.43 | 105.62 | 200.00 | 100.00 |

| 180 (r=b-a) | 300.54 | 99.55 | 300.00 | 100.00 |

| unit of stress: MPa |

2D Saturated-Unsaturated Seepage Flow Analysis

1. Outline

- This is a program for 2D steady seepage flow Analysis with isotripic material which is subjected to Darcy's law. This program can not treat unsteady or anisotropic material problem.

- This program can do the saturated-unsaturated seepage flow analysis in the vertical section, and saturated seepage flow analysis in the horizontal and vertical section.

- Von Genuchten model is used as unsaturated ground model.

- 4 node isoparametric element with 4 Gauss points is used as a 4 node element. 1 node has 1 degree of freedom which is nodal total head or nodal discharge

- Thickness of the element is unit thickness and it is not changeable.

- As boundary conditions, impervious boundary, given total head boundary, given discharge boundary and seepage face boundary can be considered.

- In coordinate system, x-direction is defined as right direction and z-direction is defined as upward direction or altitude.

- Nodal head must be inputted as total head and solution of simultaneous equations is described as total head.

- Pressure head is calculated as the difference between total head and position head.

- Simultaneous linear equations are solved using numpy.linalg.solve(A, b).

- Convergence criterion is that the case change of pressure head becomes less than 1$\times$10$^{-6}$.

Upper limit of iteration is set to 100 times.

- Input/Output file name can be defined arbitrarily with the format of space separator and those are inputted from command line of a terminal.

| Valid boundary conditions |

|---|

| Item | Description |

|---|

| Impervious boundary | No-input means impervious boundary |

| Total head given boundary | Specify the nodes and total head |

| Discharge given boundary | Specify the nodes and discharge.

Positive value of discharge means in-flow, and negative value of discharge means out-flow from a element. |

| Seepage face boundary | Specify the nodes which have the possibility of occurance of free surface. Pressure heads at these points are zero or negative value and signs of discharge shall be negative (out-flow) |

Suplimental explanation anout analysis section

- Section for analysis shall be choosen, either vertical or horizontal section.

- In the vartical section calculation, pressure head is given as the difference between total head and position head.

- In the horizontal section analysis, pressure head is the same as total head.

2. FEM program

| Program name | Description |

|---|

| py_fem_seep4.py | 2D Saturated-Unsaturated Seepage Flow Analysis program |

3. Command format for FEM analysis execution

python3 py_fem_seep4.py inp.txt out.txt

| inp.txt | : Input data file (saparated by space) |

| out.txt | : Output data file (separated by space) |

4. Input data format

npoin nele nsec koh koq kou idan # Basic values for analysis

Ak0 alpha em # Material properties

..... (1 to nsec) ..... #

node-1 node-2 node-3 node-4 isec # Element connectivity

..... (1 to nele) ..... # (counter-clockwise order of node number)

x z hvec0 # Coordinate, initial value of total head

..... (1 to npoin) ..... #

nokh Hinp # Node with given total head, given total head

..... (1 to koh) ..... # (omit data input if koh=0)

nokq Qinp # Node with given duscharge, given discharge

..... (1 to koq) ..... # (omit data input if koq=0)

noku # Node with assumed seepage face condition

..... (1 to kou) ..... # (omit data input if kou=0)

| npoin, nele, nsec | : number of nodes, number of elements, number of material sets |

| koh, koq, kou | : number of nodes with given total head, number of nodes with given discharge, number of nodes with assumed seepage face condition |

| idan | : Analysis section (0: vertical, 1: horizontal) |

| Ak0 | : saturated permeability coefficient of element |

| alpa, em | : unsaturated properties of element |

| node-1, node-2, node-3, node-4, isec | : nodes constituting an element, material set number |

| x, z, hvec0 | : x and z coordinate, initial total head for iterative calculation |

| nokh, Hinp | : node with given total head, value of total head |

| nokq, Qinp | : node with given discharge, value of discharge |

| noku | : node with assumed seepage face condition |

5. Output data format

npoin nele nsec koh koq kou idan

(Each value of above)

sec Ak0 alpha em

Ak0 : Permeability coefficient (saturated)

alpha : Un-saturated parameter

em : Un-saturated parameter

..... (1 to nsec) .....

node x z hvec qvec koh koq kou

node : Node number

x : x-coordinate

z : z-coordinate

hvec : Initial total head

qvec : Initial discharge

koh : Index of node with given total head (0: free, 1: fixed)

koq : Index of node with given discharge (0: free, 1: fixed)

kou : Index of node with assumed seepage face (0: free, 1: fixed)

..... (1 to npoin) .....

node Hinp

node : Node number

Hinp : Given total head

..... (1 to koh) .....

node Qinp

node : Node number

Qinp : Given discharge

..... (1 to koq) .....

elem i j k l sec

elem : Element number

i : Node number of start point

j : Node number of second point

k : Node number of third point

l : Node number of end point

sec : Material number

..... (1 to nele) .....

node hvec pvec qvec koh koq kou

node : Node number

hvec : Total head

pvec : Pressure head (Total head minus elevation of the node)

qvec : Discharge (+: inflow, -: outflow)

koh : Index of node with given total head (0: free, 1: fixed)

koq : Index of node with given discharge (0: free, 1: fixed)

kou : Index of node with assumed seepage face (0: free, 1: fixed)

..... (1 to npoin) .....

elem vx vz vm kr

elem : Element number

vx : Flow velocity in x-direction

vz : Flow velocity in z-direction

vm : Composed flow velocity

kr : Parameter of saturation (1: saturated, less than 1: unsaturated)

..... (1 to nele) .....

Total inflow = (total inflow discharge: positive sign)

Total outflow= (total outflow discharge: negative sign)

Max.velocity in all area = (maximum velocity in all area)

Max.velocity in inflow area = (maximum velocity in inflow area)

Max.velocity in outflow area = (maximum velocity in outflow area)

iii=(number of itaration)

icount=(converged number of degrees of freedom)

kop=(number of pressured nodes)

n=(total degrees of freedom) time=(calculation time)

| hvec, pvec, qvec | : total head, pressure head, nodal discharge |

| vx, vz, vm | : velocity in x-direction, velocity in z-direction, composed velocity |

| kr | : Relative hydraulic conductivity function (1: saturated, <1: unsaturated) |

6. Output sample

6.1 Input data sample and auxiliary program

Plotting method of the pressure head contour

Each node coordinate which forms a triangle is set as $(x, z)$, and the value of pressure head is set as $y$.

Under above setting, an equation of a plane passing through 3 points $(x_1,y_1,z_1)$, $(x_2,y_2,z_2)$, $(x_3,y_3,z_3)$ in a 3D space can be defined as follow:

\begin{equation}

a*x+b*y+c*z+d=0

\end{equation}

\begin{align}

a=&(y_2-y_1)*(z_3-z_1)-(y_3-y_1)*(z_2-z_1) \\

b=&(z_2-z_1)*(x_3-x_1)-(z_3-z_1)*(x_2-x_1) \\

c=&(x_2-x_1)*(y_3-y_1)-(x_3-x_1)*(y_2-y_1) \\

d=&-x_1*\{(y_2-y_1)*(z_3-z_1)-(y_3-y_1)*(z_2-z_1)\} \\

&-y_1*\{(z_2-z_1)*(x_3-x_1)-(z_3-z_1)*(x_2-x_1)\} \\

&-z_1*\{(x_2-x_1)*(y_3-y_1)-(x_3-x_1)*(y_2-y_1)\}

\end{align}

And an equation of a line passing through a point $y=y_c$ can be defined as follow:

\begin{align}

z=&-a/c*x-b/c*y_c-d/c \\

=&a'*x+b' \\

&a'=-a/c \\

&b'=-b/c*y_c-d/c

\end{align}

A point $(x_x,z_z)$ which has the minimum distance from a point $(x_g,z_g)$ to a line $z=a'*x+b'$ can be obtained as follow:

\begin{equation}

\begin{cases}

&x_x=\cfrac{x_g+z_g*a'-a'*b'}{1+a'*a'} \\

&z_z=a'*x_x+b'

\end{cases}

\end{equation}

Using above, a point coordinate $(x_x, z_z)$ which has a pressure head value $y_c$ can be calculated.

|

|

It is impossible to create a plane with arbitrary 4 points in the 3D space. Therefore, for 4 nodes elements, the area of element is divided to 4 traiangle areas to create a plane for each triangle area. When the node numbers which forms 4 node element is assumed (1,2,3,4) referring the left drawing, the usable combinations of nodes becomes (1,2,3), (2,3,4), (3,4,1), (4,1,2) with the sequence of counterclockwise direction.

|

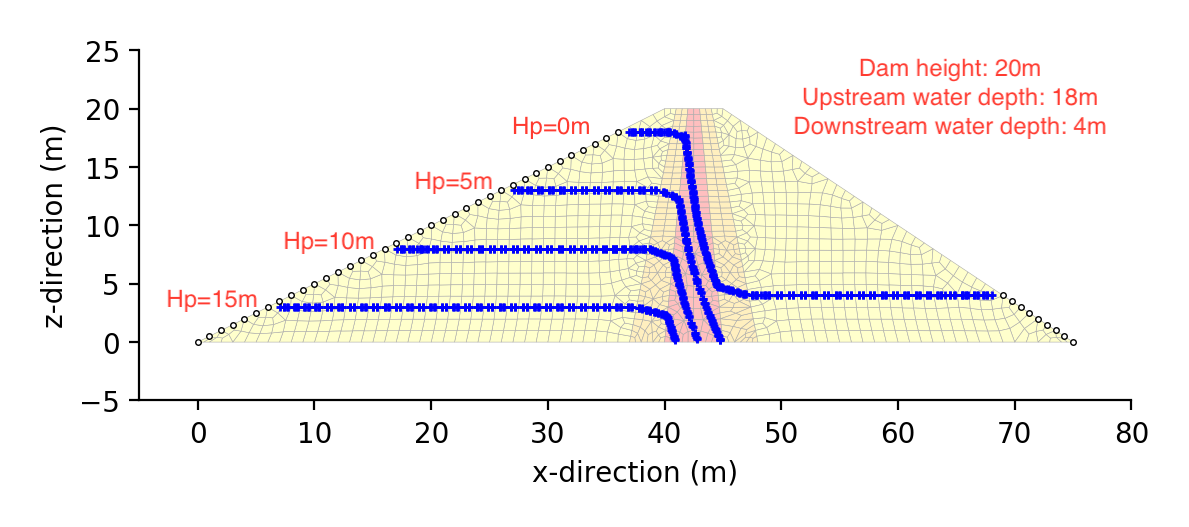

6.2 Outline of sample analysis model

Sample model is a zoned rock fill type dam which has height of 20m. In the sample analysis, a steady seepage flow analysis was carried out under the conditions shown below.

Height

(m) | Top width

(m) | Upstream

slope | Downstream

slope | Upstream

water depth (m) | Downstream

water depth (m) |

|---|

| 20.0 | 5.0 | 1:2.0 | 1:1.5 | 18.0 | 4.0 |

| Material properties |

|---|

| Zone | Permeability

k (m/s) | α

(m$^{-1}$) | m |

|---|

| Upstream shell | 1 x 10$^{-2}$ | 0.1 | 0.7 |

| Upstream filter | 1 x 10$^{-5}$ | 0.1 | 0.7 |

| Center core | 1 x 10$^{-6}$ | 0.1 | 0.7 |

| Downstream filter | 1 x 10$^{-5}$ | 0.1 | 0.7 |

| Downstream shell | 1 x 10$^{-2}$ | 0.1 | 0.7 |

6.3 Execution command for FEM analysis and drawing

python3 py_fem_seep4.py inp_zone4.txt out_zone4.txt

python3 py_seep4_cont.py out_zone4.txt

python3 py_seep4_vect.py out_zone4.txt

| inp_zone4.txt | : FEM analysis input data (separated by space) |

| out_zone4.txt | : FEM analysis output data (separated by space) |

In the drawing program 'py_seep4_cont.py', a image file named '_fig_seep4_cont.png' is created automatically. Although the drawing range is set automattically, the contour pitch of pressure head shall be amended considering the result of the analysis.

In the drawing program 'py_seep4_vect.py', a image file named '_fig_seep4_vect.png' is created automatically.

6.4 Sample drawings

(1) Simple pressure head contour

A png image which was drawn using a program 'py_seep_cont.py' is shown below.

Pressure head values (Hp=0m,5m,10m,15m) which are shown using red color character and some information shown in upper-right location are added later using Mac application of 'Preview'. (Preview $\rightarrow$ Tools $\rightarrow$ Annotate $\rightarrow$ Text)

(Notice) In the actural zoned rockfill type dam, it is already known that the sudden pressure head drop in the core zone has not been observed and the phenomena of pressure drop has been observed along the boundary of the core zone and filter zone. Please understand that this analysis is only a sample for the test of program functions.

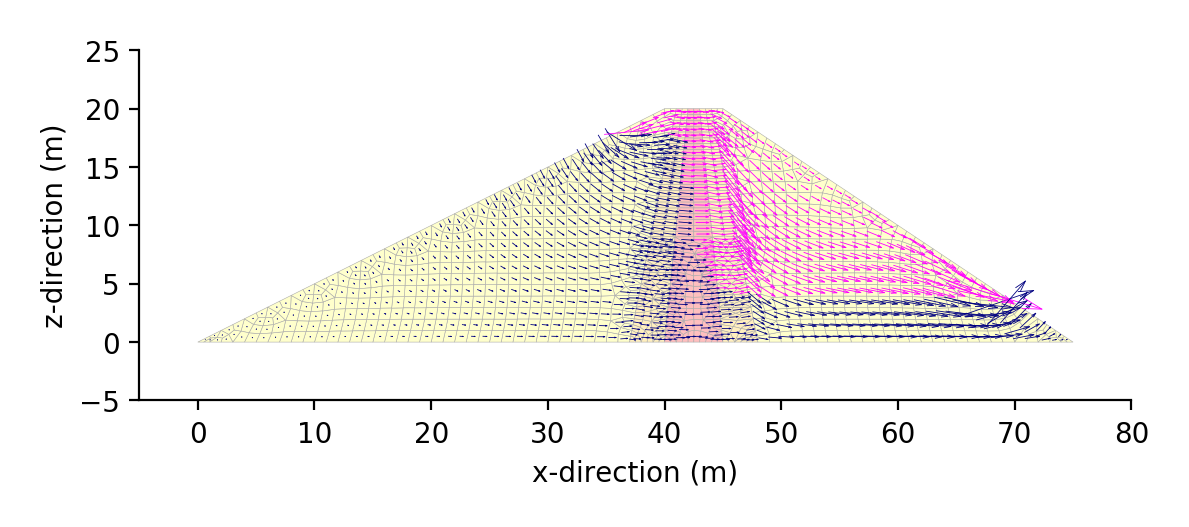

(2) Velocity vector diagram

A png image which was drawn using a program 'py_seep_vect.py' is shown below.

Mean velocity vectors for saturated elements are shown using 'Navy' color, and mean velocity vectors for unsaturated elements are shown using 'Magenta' color.

Although it is simple and convenient to use a matplot command 'quiver' for vector plotting, 'plot' command is used in this program because of some troubles in the drawing work.

2D Thermal Conductivity Analysis

1. Outline

- This is a program for 2D unsteady thermal conductivity analysis with isotropic material. This program can not treat steady ot anisotropic material problem.

- Thickness of the element is unit thickness and it is not changeable.

- As boundary conditions, thermal insulation boundary, temperature given boundary and heat transfer boundary can be considered.

- Heating material such as cement concretecan also be used .

- 4 node isoparametric element with 4 Gauss points is used. 1 node has 1 degree of freedom of temperature or heat flux.

- In coordinate system, x-direction is defined as right-direction and y-direction is defined as upward direction.

- Crank-Nicolson method is used for the discretization of the time.

- Simultaneous linear equations are solved using numpy.linalg.inv(A).

Although this solving process has repeating process for time history analysis, matrix for calculation is not changed if the time increment is not changed.

Therefore, to calculate an inverse matrix is carried out only one time, and it is used to calculate the time history of the temperature until the end of the calculation time.

- Input/Output file name can be defined arbitrarily with the format of space separater and those are inputted as command line arguments of a terminal.

In addition, it is necessary to prepare the input file for time history of node temperatures of given temperature boundary and side temperatures of heat transfer boundary.

| Valid boundary conditions |

|---|

| Item | Description |

|---|

| Thermal insulation boundary | No input means thermal insulation boundary |

| Temperature given boundary | Specify the nodes and time history of temperature at specified nodes |

| Heat transfer boundary | Specify the sides of element, heat transfer coefficient and time history of temperature at outside |

Supplemrntal explanation of heating material

Heating material can be used like a cement concrete.

Properties of heating materials are inputted as element material characteristics.

In this program, heat generation of cement concrete is imitated and the adiabatic temperature rise shown below formula can be considered.

\begin{equation}

T=K\cdot(1-e^{-\alpha\cdot t})

\end{equation}

where, $T$: adiabatic temperature rise, $K$: maximum temperature rise, $\alpha$: coefficient of heat release rate, $t$: time.

In this program, $K$ (Tk) and $\alpha$ (Al) become input data and heat generation rate per unit area is calculated in calculation process.

Supplemental explanation of heat transfer boundary

It is necessary for heat transfer boundary to be defined as a side of an element.

Therefore, element number and one node which forms a heat transfer boundary shall be inputted as input data.

Since the node numbers which forms an element are inputted with the sequence of counterclockwise in FEM input data, the side can be identified by specifying a first node of the side with heat transfer boundary.

2. FEM program

| Program name | Description |

|---|

| py_fem_heat.py | 2D Thermal Conductivity Analysis program |

3. Command format for FEM analysis execution

python3 py_fem_heat.py inp1.txt inp2.txt out.txt

| inp1.txt | : First input data file for analysis model (separated by space) |

| inp2.txt | : Second input data file for time histories of temperature given nodes or outside temperature of heat transfer boundary (separated by space) |

| out.txt | : Output data file (separated by space) |

4. Input data format

(1) Analysis model data

npoin nele nsec kot koc delta # Basic values for analysis

Ak Ac Arho Tk Al # Material properties

..... (1 to nsec) ..... #

node-1 node-2 node-3 node-4 isec # Element connectivity, Material set number

..... (1 to nele) ..... # (counterclockwise order of node numbers)

x y T0 # Coordinates of node, initial temperature of node

..... (1 to npoin) ..... # (x: right-direction, y: upward direction)

nokt # Node number of temperature given boundary

..... (1 to kot) ..... # (Omit data input if kot=0)

nekc_0 nekc_1 alphac # Element number, node number defined side, heat transfer rate

..... (1 to koc) ..... # (Omit data input if koc=0)

n1out # Number of nodes for output of temperature time history

n1node_1 ..... (1 line input) ..... # Node number for above

n2out # frequency of output of temperatures of all nodes

n2step_1 ..... (1 line input) ..... # Time step number for above (Omit data input if ntout=0)

| npoin, nele, nsec | : number of nodes, number of elements, number of material sets |

| kot, koc | : number of temperature given nodes, number of heat transfer boundary sides |

| delta | : time increment |

| Ak, Ac, Arho | : heat conductivity coefficient, specific heat, unit weight |

| Tk, Al | : maximum temperature rise, coefficient of heat release rate (for heating material) |

| x, y, T0 | : x and y coordinates, initial temperature of node |

| nokt | : node with temperature given boundary |

| nekc_0, nekc_1, alphac | : element and first node with heat transfer boundary side, heat transfer rate |

| n1out | : number of nodes for all time history output |

| n1node | : node numbers for all time history output |

| n2out | : number of steps for all nodes temperature output |

| n2step | : step numbers for all nodes temperature output |

(2) Time history data for temperature given nodes or heat transfer boundary sides

1 TE[1] ... TE[kot] TC[1] ... TC[koc] # data of 1st time step

2 TE[1] ... TE[kot] TC[1] ... TC[koc] # data of 2nd time step

3 TE[1] ... TE[kot] TC[1] ... TC[koc] #

..... (repeating until end time) ..... #

itime TE[1] ... TE[kot] TC[1] ... TC[koc] #

| kot | : number of nodes with temperature given boundary |

| koc | : number of sides with heat transfer boundary |

| TE[1~kot] | : temperature time history at temperature given boundary node |

| TC[1~koc] | : time history of outside temperature at heat transfer boundary side |

5. Output data format

npoin nele nsec kot koc delta niii n1out n2out

(Each value of above)

sec Ak Ac Arho Tk Al

sec : Material number

Ak : Heat conductivity coefficient

Ac : Specific heat

Arho : Unit weight

Tk : Maximum temperature rize

Al : Heat release rate

..... (1 to nsec) .....

node x y tempe0 Tfix

node : Node number

x : x-ccordinate

y : y-coordinate

tempe0 : Initial temperature

Tfix : Index of node with given temperature (0: free, 1: fixed)

..... (1 to npoin) .....

nek0 nek1 alphac

nek0 : Element number with heat transfer boundary

nek1 : Node number to specify heat transfer boundary side of an element

alphac : Heat transfer rate at the specified side of an element

..... (1 to koc) .....

elem i j k l sec

elem : Element number

i : Node number of start point

j : Node number of second point

k : Node number of third point

l : Node number of end point

sec : Material number

..... (1 to nele) .....

iii ttime Node_(xx) Node_(xx) Node_(xx) .....

iii : Time step

ttime : Time

Node-(xx) : Node number

Time historis of each node temperature are written.

..... (0 to end of calculation time) .....

node t=0.0 t=(xx) t=(xx)0 t=(xx) .....

node : Node number

t=(xx) : Specified time

Node temperatures at specified time are written.

..... (1 to npoin) .....

n=(total degrees of freedom) time=(calculation time)

6. Output sample

6.1 Input data sample and auxiliary program

| Program name | Description |

|---|

| inp_div20_model.txt | First FEM analyis input data (analysis model data) |

| inp_div20_thist.txt | Second FEM analysis input data (temperature time history for specified nodes or sides) |

| py_heat_2D.py | Drawing program of temperature time history (matplotlib) |

| py_heat_3D.py | 3D drawing program of temperature distribution at specified time (GMT) |

6.2 Outline of sample analysis model

Model shape is a square with 1m length side and inside element is formed by heating material. 4 sides of the model has heat transfer boundary. Material properties and analysis conditions are shown below.

| Characteristics of model |

|---|

| Heat conductivity coefficient | 2.5 kcal/m h $^{\circ}$C |

| Specific heat | 0.28 kcal/kg $^{\circ}$C |

| Unit weight | 2350 kg/m$^3$ |

| Heat transfer rate | 10 kcal/m$^2$ h $^{\circ}$C |

Adiabatic temperature raise

(heating material) | $T=K\cdot(1-e^{-\alpha t})$, K=40$^{\circ}$C, α=0.2, t: hour |

| Model | 1m square area, 441 nodes, 400 elements |

| Conditions for analysis |

|---|

| Initial temperature of domain | 20 $^{\circ}$C for all nodes |

| Boundary condition | 4 sides have heat transfer boundary with outside temperature of 10 $^{\circ}$C |

| Heat generation of elements | Considered for all elements |

6.3 Execution command for FEM analysis and drawing

python3 py_fem_heat.py inp_div20_model.txt inp_div20_thist.txt out_div20.txt

python3 py_heat_2D.py out_div20.txt

python3 py_heat_3D.py out_div20.txt

bash _a_gmt_3D.txt

mogrify -trim -density 300 -bordercolor 'transparent' -border 10x10 -format png *.eps

rm *.eps

| inp_div20_model.txt | : First FEM analysis input data of modeling (separated by space) |

| inp_div20_thist.txt | : Second FEM analysis data of temperature time histories (separated by space) |

| out_div20.txt | : FEM analysis output data (separated by space) |

| _a_gmt_3D.txt | : GMT script by 'py_heat_3D.py' |

Program 'py_heat_2D.py'

Program 'py_heat_2D.py' creates a image file of '_fig_tem_his.png' aotomatically.

Program 'py_heat_3D.py'

- This program creates a GMT (Generic Mapping Tools) script named '_a_gmt_3D.txt' automatically.

- By execution of above GMT script, eps image files named '_fig_gmt_xyz_0.eps', '_fig_gmt_xyz_1.eps', .... are created automatically.

- In above execution command, eps image files by GMT are converted to png image files using ImageMagick command 'mogrify'.

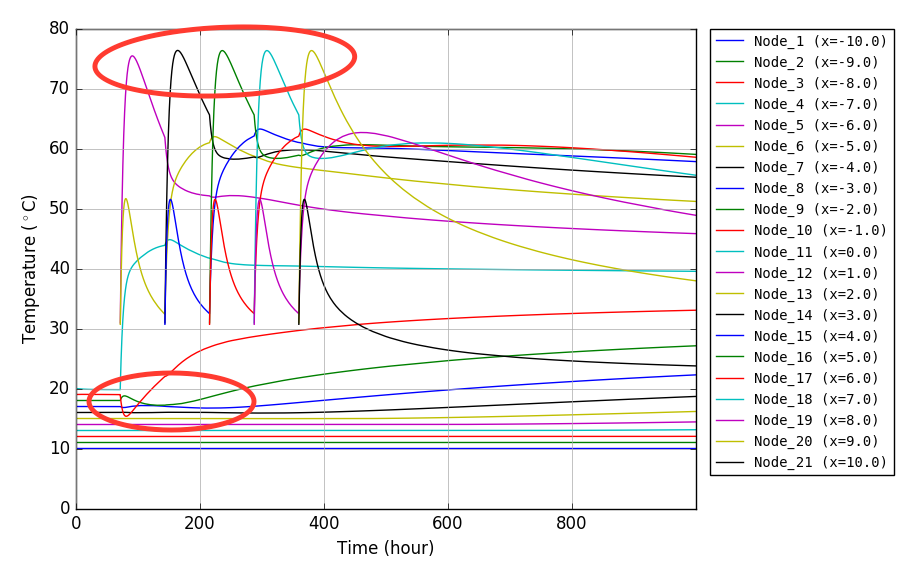

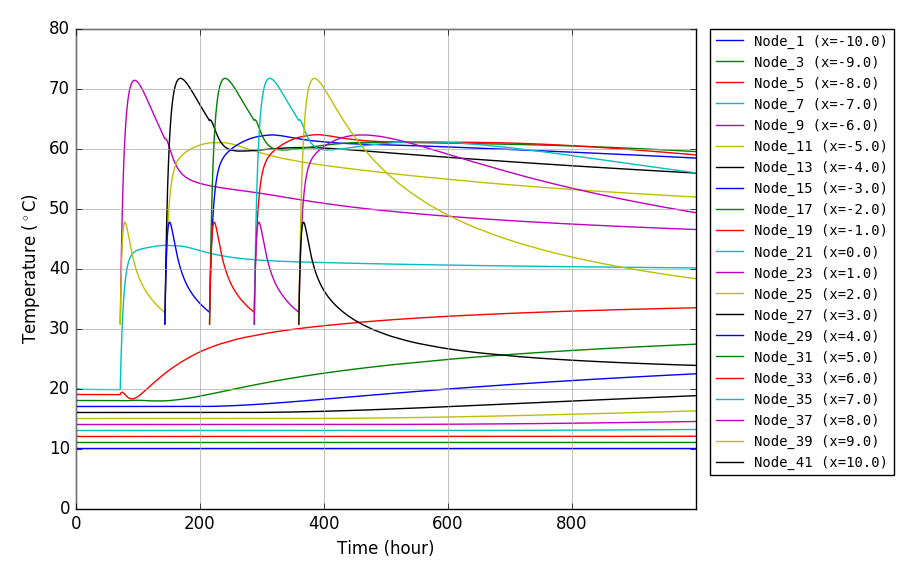

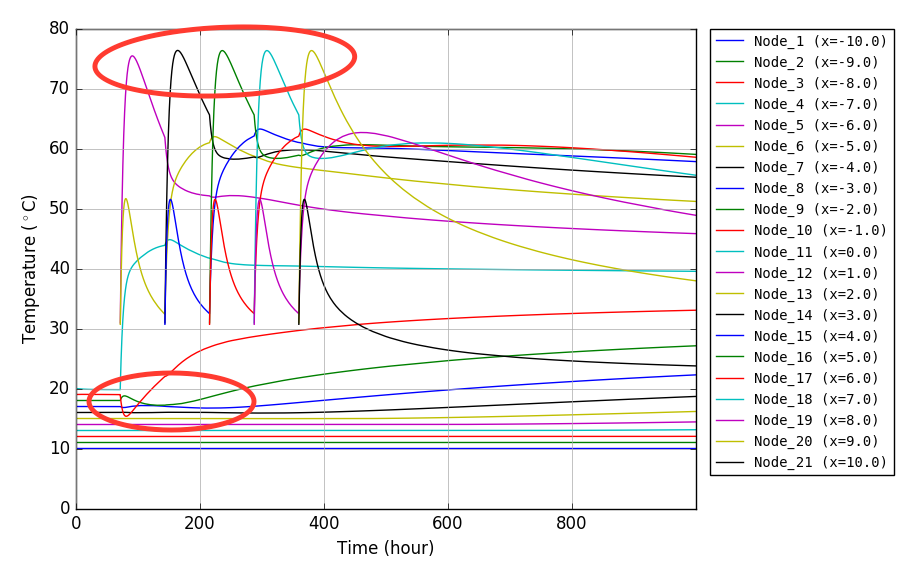

6.4 Sample drawing

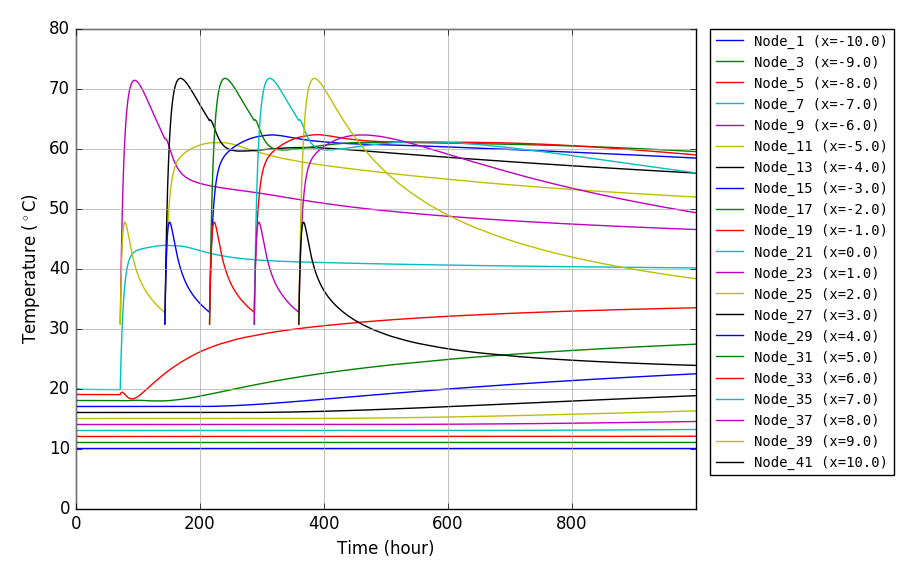

(1) Temperature time histories at specified nodes

A image created by 'py_heat_2D.py' is shown below.

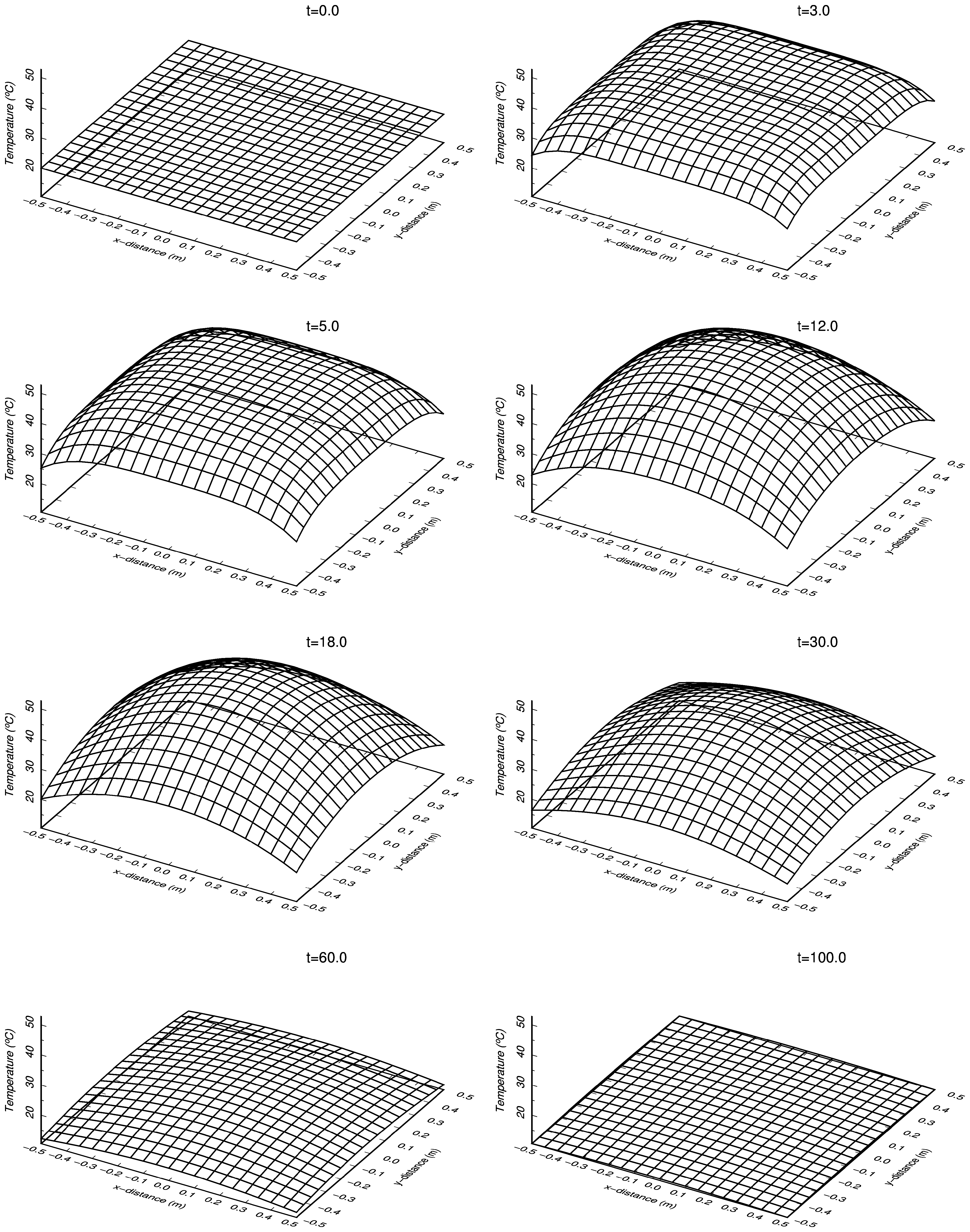

(2) 3D temperature distributions at specified step

A image created by 'py_heat_3D.py' and GMT is shown below. Below image is created by integration of 8 image files using TeX and ImageMagick. Unit of 't' in below image is 'hours'.

2D Frame Vibration Analysis

1. Outline

(1) Time history response analysis

- This is a program for 2D frame time history response analysis with elastic material and small displacement theorey

- Beam element with 2 nodes is used. 1 node has 3 degrees of freedom in horizontal displacement, vertical displacement and rotation.

- Nodal external force can be given as a rate load, and only one acceleration time history can be given.

Actually, the product of nodal external unit forces and acceleration becomes the loads to structure.

- In coordinate system, x-direction is defined as right-direction, y-direction is defined as upward direction and counterclockwise direction is defined as positive in rotation.

- Simultaneous linear equations are solved using numpy.linalg.inv(A).

Although this solving process has repeating process for time history analysis, matrix for calculation is not changed if the time increment is not changed.

Therefore, to calculate an inverse matrix is carried out only one time, and it is used to calculate the time history response until the end of the calculation time.

- Input/Output file name can be defined arbitrarily with the format of space separater and those are inputted as command line arguments of a terminal.

In addition, it is necessary to prepare the input file for acceleration time history.

| Valid boundary conditions |

|---|

| Item | Description |

|---|

| External force | Specify the loded nodes and rate load values |

| Forced displacement | Specify the nodes with fixed conditions. Only perfect fixed condition (zero displacement) can be treated |

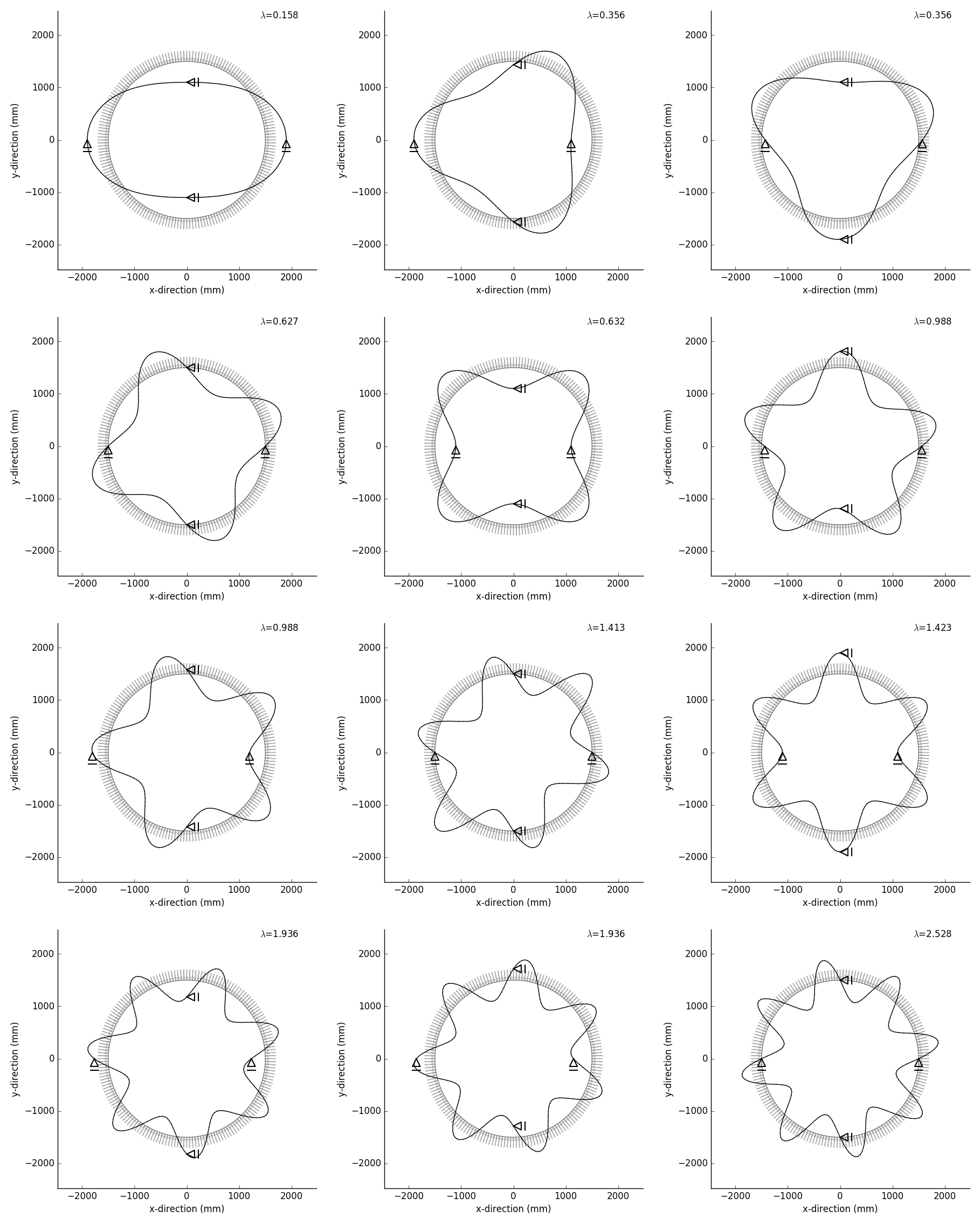

(2) Eigenvalue analysis

- This is a program for 2D frame vibration eigen value analysis with elastic material and small displacement theorey

- Beam element with 2 nodes is used. 1 node has 3 degrees of freedom in horizontal displacement, vertical displacement and rotation.

- In coordinate system, x-direction is defined as right-direction, y-direction is defined as upward direction and counterclockwise direction is defined as positive in rotation.

- Characteristic equation are solved using w,vr=scipy.linalg.eig(K, M) as a generalized eigenvalue problem

- Input/Output file name can be defined arbitrarily with the format of space separater and those are inputted as command line arguments of a terminal.

| Valid boundary conditions |

|---|

| Item | Description |

|---|

| Forced displacement | Specify the nodes with fixed conditions. Only perfect fixed condition (zero displacement) can be treated |

2. FEM program

| Filename | Description |

|---|

| py_fem_vfrm.py | 2D frame time history response analysis program |

| py_fem_efrm.py | 2D frame vibration eigenvalue analysis program |

3. Command format, input and output data format for time history response analysis program

3.1 Command format for FEM analysis execution

Two input files are required for this program. One is for structural model data, another is for acceleration time history data.

python3 py_fem_vfrm.py inp1.txt inp2.txr out.txt

| inp1.txt | : First input data for structural model (separated by space) |

| inp2.txt | : Second input data including acceleration time history (separated by space) |

| out.txt | : Output data file (separated by space) |

3.2 Input file format

(1) First input data for structural model

npoin nele nsec npfix nlod # Basic values for analysis

E A I gamma zeta_m zeta_k # Material properties

..... (1 to nsec) ..... #

node_1 node_2 isec # Element connectivity, material set number

..... (1 to nele) ..... #

x y # Node coordinate

..... (1 to npoin) ..... #

lp fix_x fix_y fix_r # Restricted node and restrict conditions

..... (1 to npfix) ..... #

lp fp_x fp_y fp_r # Loaded node and loading conditions

..... (1 to nlod) ..... # (omit data input if nlod=0)

| npoin, nele, nsec | : number of nodes, number of elements, number of material sets |

| npfix, nlod | : number of restricted nodes, number of loaded nodes |

| E, A, I, gamma | : elastic modulus, section area, moment of inertia, unit weight |

| zeta_m, zeta_k | : coefficients of Rayleigh damping |

| node_1, node_2, isec | : nodes forms an element, material set number |

| x, y | : x and y coordinates |

| lp, fix_x, fix_y, fix_r | : node, kind of restriction in x, y-direction and rotation, (0: free, 1: fixed) |

| lp, fp_x, fp_y, fp_r | : loaded node, loading rate in x, y-direction and rotation |

(2) Second input data including acceleration time history

delta # time increment (sec)

acc1 # start of acceleration data

acc2

acc3

....

(until end of data)

3.3 Output data format

npoin nele nsec npfix nlod ndoutx ndouty nfout delta nnn

(Each value of above)

sec E A I gamma zeta_m zeta_k

sec : Material number

E : Elastic modulus

A : Section area

I : Moment of inertia

gamma : Unit weight

zeta_m : Coefficient of Rayleigh damping for mass matrix

zeta_k : Coefficient of Rayleigh damping for stiffness matrix

..... (1 to nsec) .....

node x y fx fy fr kox koy kor

node : Node number

x : x-coordinate

y : y-coordinate

fx : Load in x-direction

fy : Load in y-direction

fr : Moment load

kox : Index of restriction in x-direction (0: free, 1: fixed)

koy : Index of restriction in y-direction (0: free, 1: fixed)

kor : Index of restriction in rotation (0: free, 1: fixed)

..... (1 to npoin) .....

elem i j sec

elem : Element number

i : Node number of start point

j : Node number of end point

sec : Material number

..... (1 to nele) .....

step time acc_inp dis_x(ii) vel_x(ii) acc_x(ii) Ni(ne)node Si(ne) Mi(ne)

step : Time step

time : Time

acc_inp : Input acceleration

dis_x(ii) : Displacement in x-direction at node-ii

vel_x(ii) : Velocity in x-direction at node-ii

acc_x(ii) : Acceleration in x-direction at node-ii

Ni(ne) : Axial force at node-i in element-ne

Si(ne) : Shear force at node-i in element-ne

Mi(ne) : Moment at node-i in element-ne

..... (to end of time step) .....

n=(total degrees of freedom) time=(calculation time)

| time, acc_inp | : time, input acceleration |

| dis, vel, acc | : displacement, velocity, acceleration |

| N, S, M | : axial force, shearing force, moment |

| n | : Total degrees of freedom (the number of the variables) |

| time | : Calculation time |

4. Command format, input and output data format for vibration eigenvalue analysis program

4.1 Command format for FEM analysis execution

python3 py_fem_efrm.py inp.txt out.txt

| inp.txt | : FEM analysis input data (separated by space) |

| out.txt | : FEM analysis output data (separated by space) |

4.2 Input data format

npoin nele nsec npfix # Basic values for analysis

E A I gamma # Material properties

..... (1 to nsec) ..... #

node_1 node_2 isec # Element connectivity, material set number

..... (1 to nele) ..... #

x y # Node coordinate

..... (1 to npoin) ..... #

lp fix_x fix_y fix_r # Restricted node and restrict conditions

..... (1 to npfix) ..... #

| npoin, nele, nsec, npfix | : number of nodes, number of elements, number of material sets, number of restricted nodes |

| E, A, I, gamma | : elastic modulus, section area, moment of inertia, unit weight |

| node_1, node_2, isec | : nodes forms an element, material set number |

| x, y | : x and y coordinates |

| lp, fix_x, fix_y, fix_r | : node, kind of restriction in x, y-direction and rotation, (0: free, 1: fixed) |

4.3 Output data format

npoin nele nsec npfix

(Each value of above)

sec E A I gamma

sec : Material number

E : Elastic modulus

A : Section area

I : Moment of inertia

gamma : Unit weight

..... (1 to nsec) .....

node x y kox koy kor

node : Node number

x : x-coordinate

y : y-coordinate

kox : Index of restriction in x-direction (0: free, 1: fixed)

koy : Index of restriction in y-direction (0: free, 1: fixed)

kor : Index of restriction in rotation (0: free, 1: fixed)

..... (1 to npoin) .....

elem i j sec

elem : Element number

i : Node number of start point

j : Node number of end point

sec : Material number

..... (1 to nele) .....

Order 1 2 3 ......

fn(Hz) w[1] w[2] w[3] ......

v[ 1] v[1,1] v[1,2] v[1,3] ......

v[ 2] v[1,1] v[1,2] v[1,3] ......

...... ...... ...... ...... ......

v[ n] v[1,1] v[1,2] v[1,3] ......

Order Ranking

w[i] : Natural frequency (eigen value)

v[j,i] : Element of eigen vector

n=(total degrees of freedom) time=(calculation time)

(Notice)

Regarding the treatment of restricted nodes in this eigenvalue analysis, since the degrees of freedom is not changed and the number of variables is kept for eigen value calculation, the eigenvalues equivalent to restricted degrees of freedom are concentrated to small value side and they have the same values by small order sorting.

And eigen vector equivalent to restricted degrees of freedom has special values which is formed only one and zero.

Using this character, the eigenvalues and eigen vectors equivalent to restricted degrees of freedom are not written in the output file.

Following is a sample of sorting result of eigenvalues.

[ 1.59154943e-01 1.59154943e-01 1.59154943e-01 1.59154943e-01

1.59154943e-01 1.59154943e-01 1.59154943e-01 1.59154943e-01

1.59154943e-01 1.59154943e-01 1.59154943e-01 1.59154943e-01

1.59154943e-01 2.35776685e+00 1.47763490e+01 4.13833696e+01

8.11515057e+01 1.34359374e+02 2.01285622e+02 2.82413495e+02

3.78356230e+02 4.89209902e+02 6.08158484e+02 8.09431960e+02

9.77895783e+02 1.18543706e+03 1.43074344e+03 1.71924912e+03

2.05623517e+03 2.44043231e+03 2.84908857e+03 3.20838993e+03

4.01526229e+03]

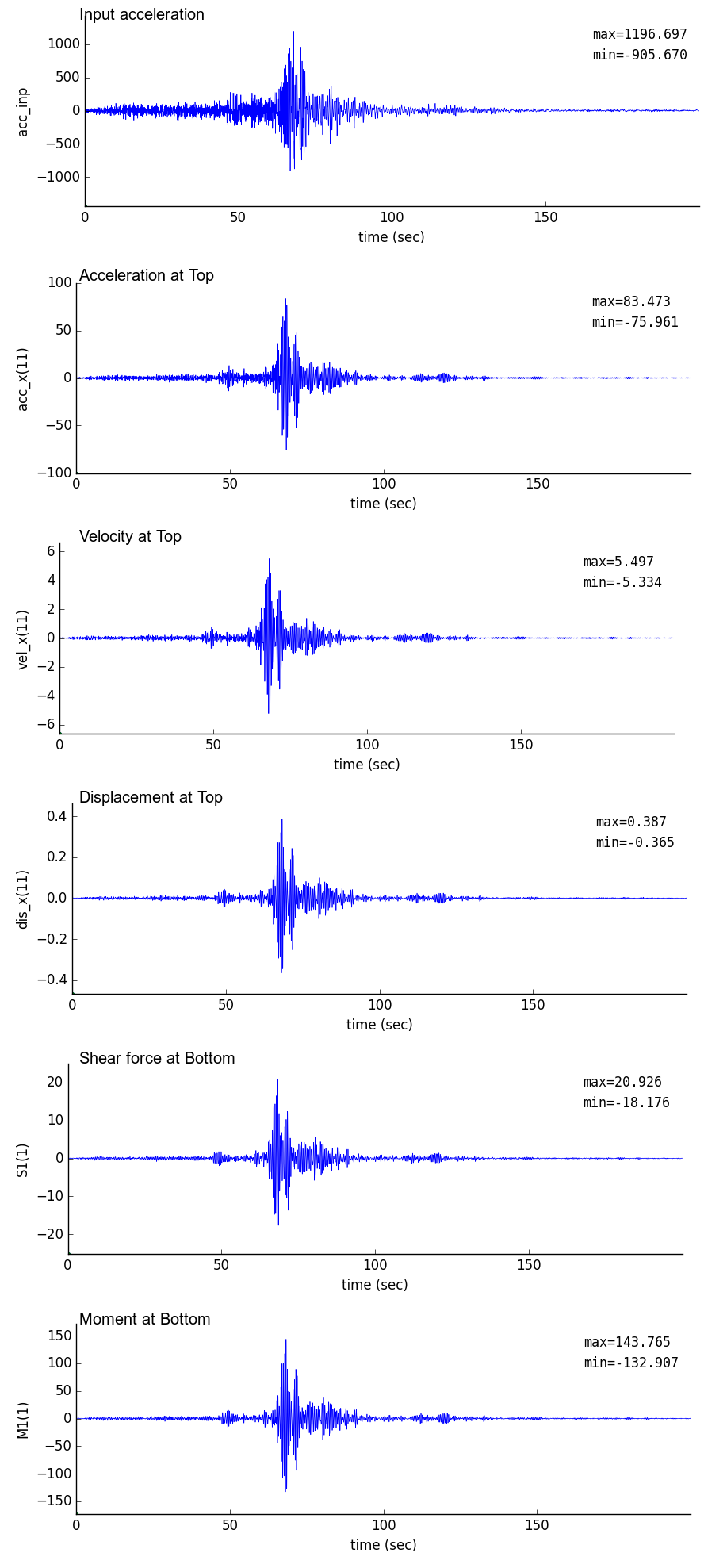

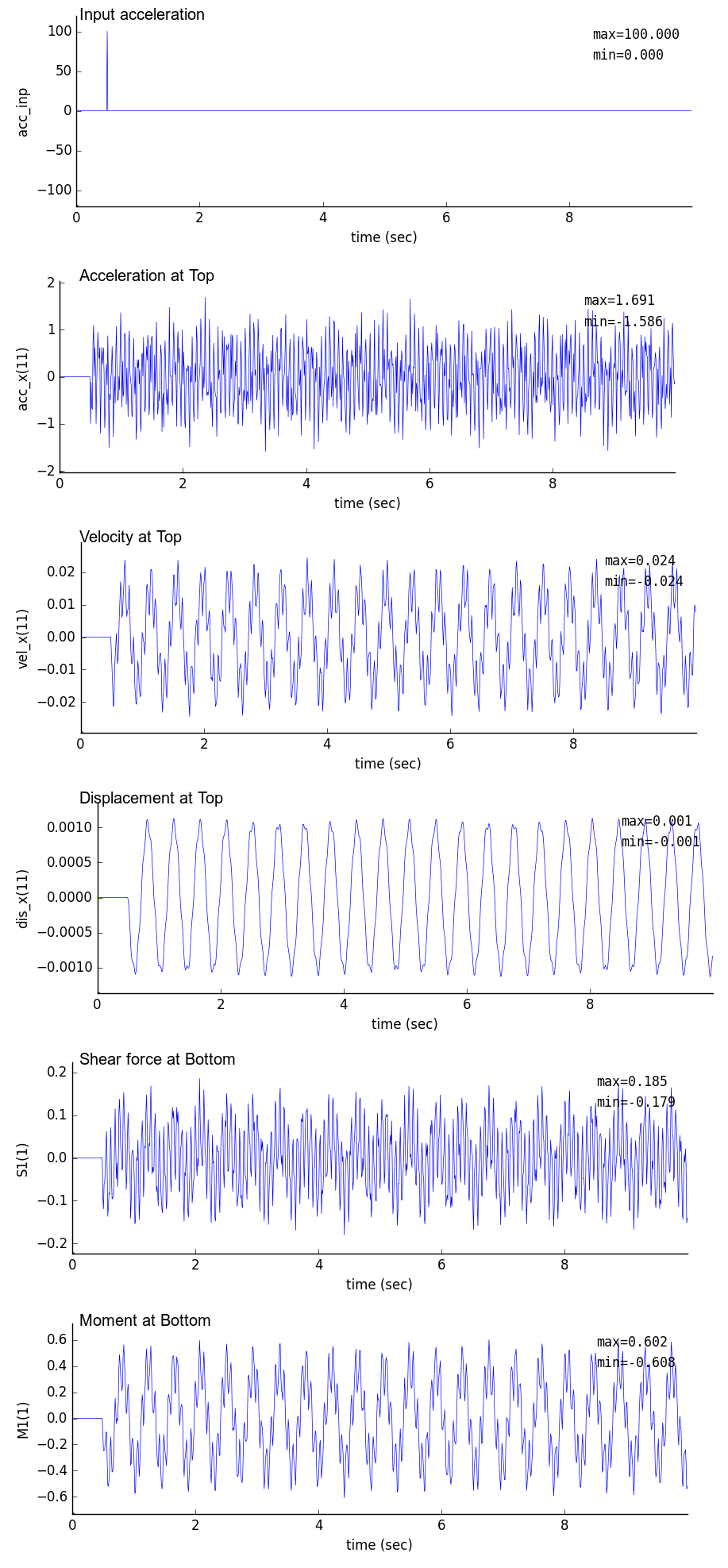

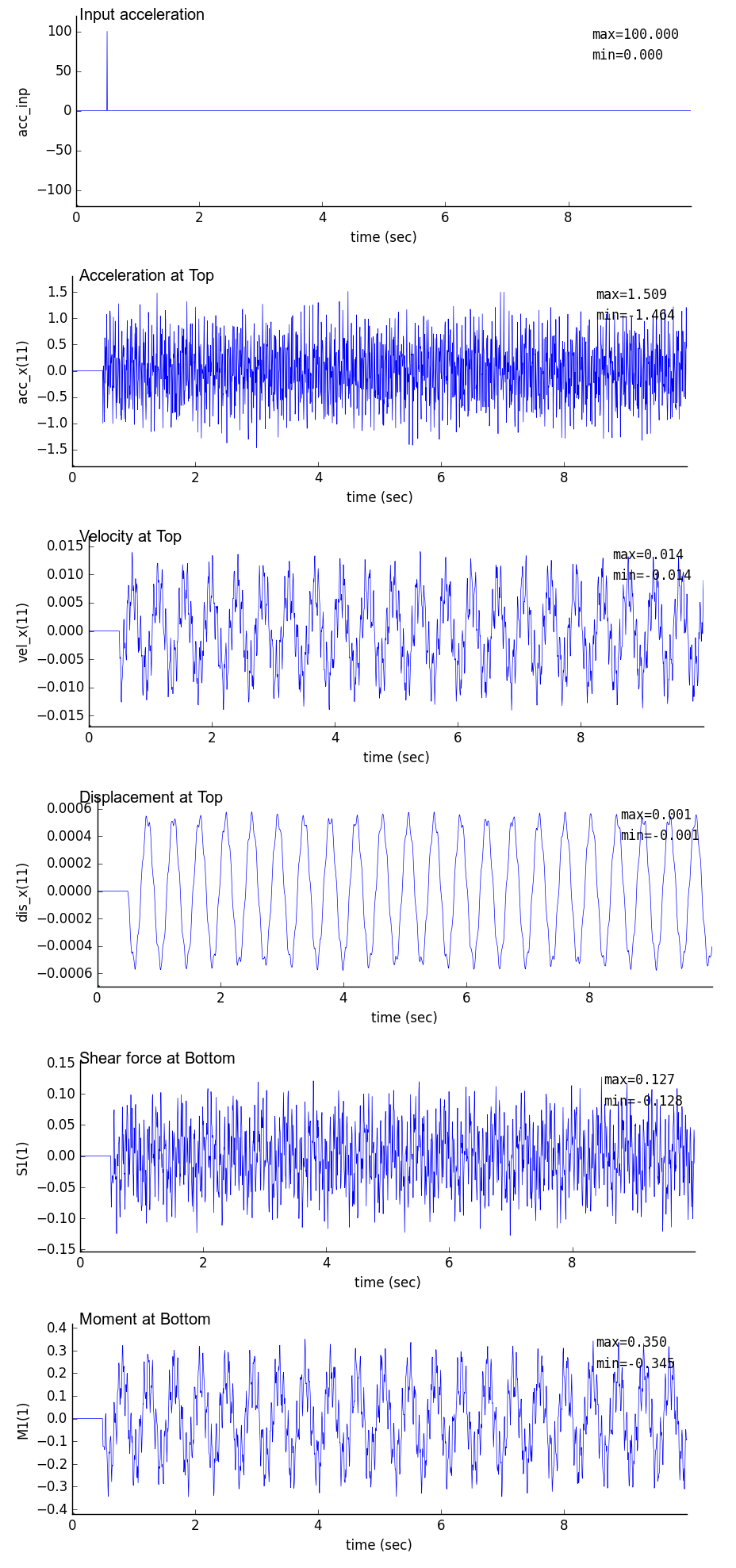

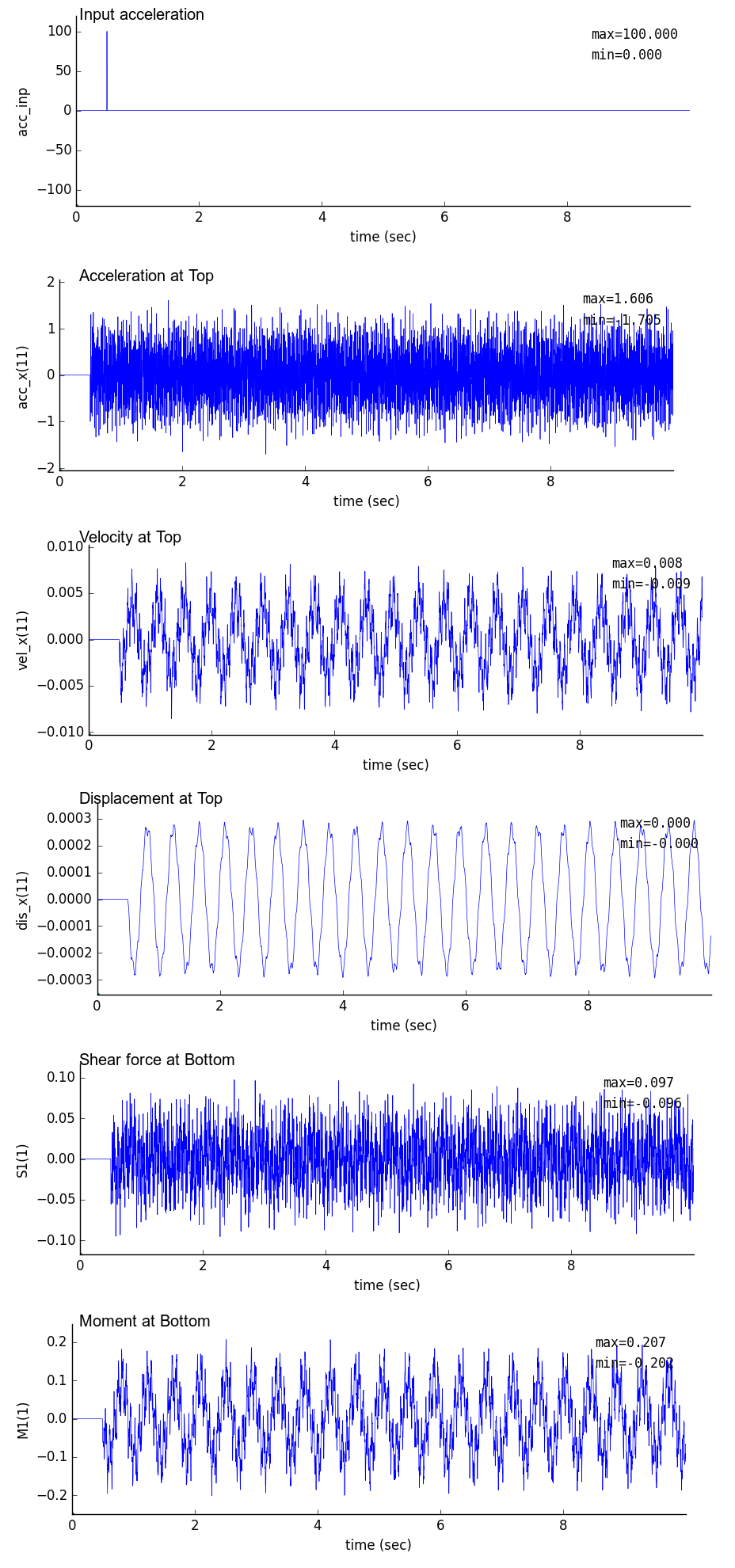

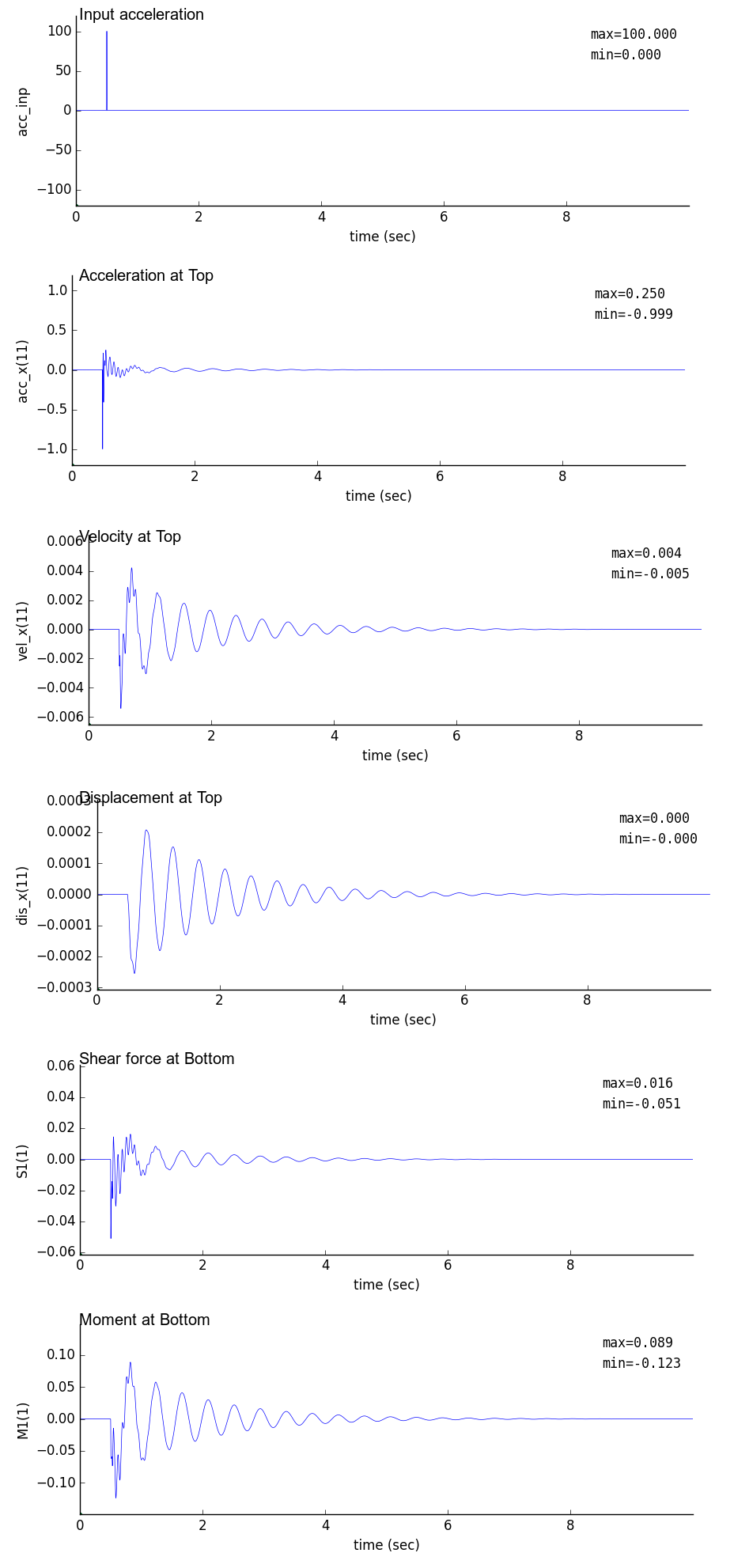

5. Output sample (Gauss wave input)

5.1 Auxiliary program

| Program name | Description |

|---|

| py_fig_vfrm.py | Drawing program for response time history and Fourier spectra (matplotlib) |

| py_gauss.py | Program for Gauss wave creation (max. 100gal) |

| py_im.py | Text addition program to image file using ImageMagick |

| py_fn_canti.py | Program for natural frequency calculation of cantilever using scipy |

| py_fig_efrm_mode.py | Drawing program of natural vibration mode (matplotlib) |

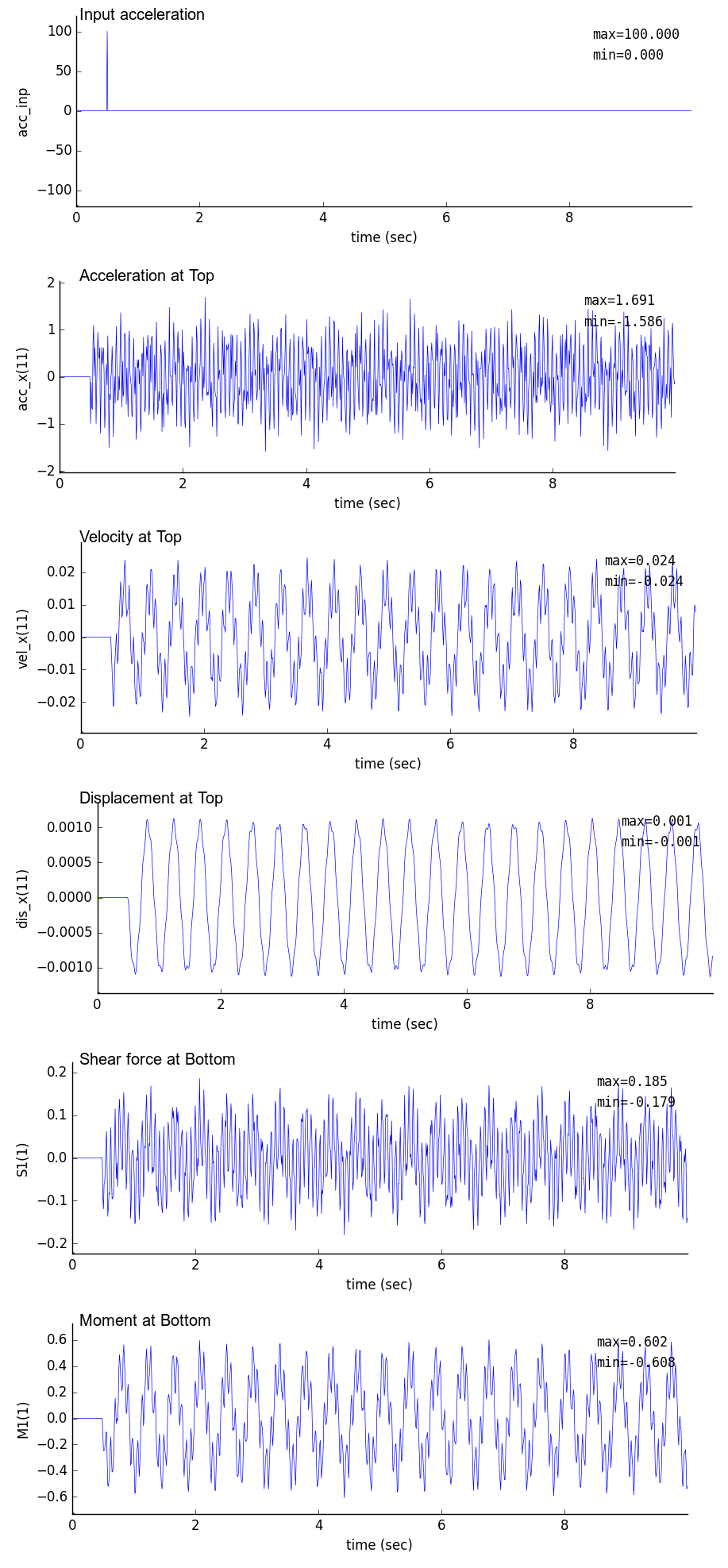

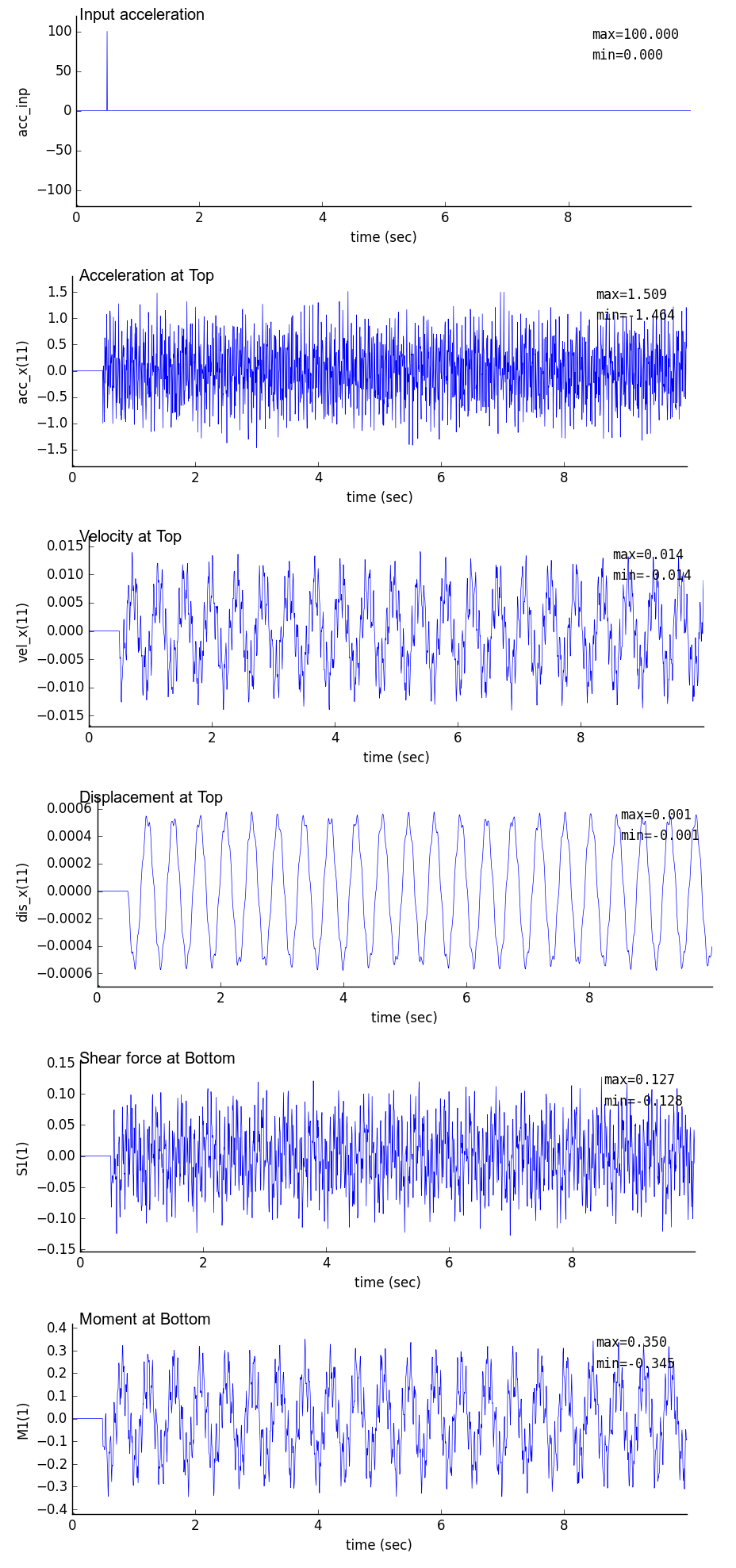

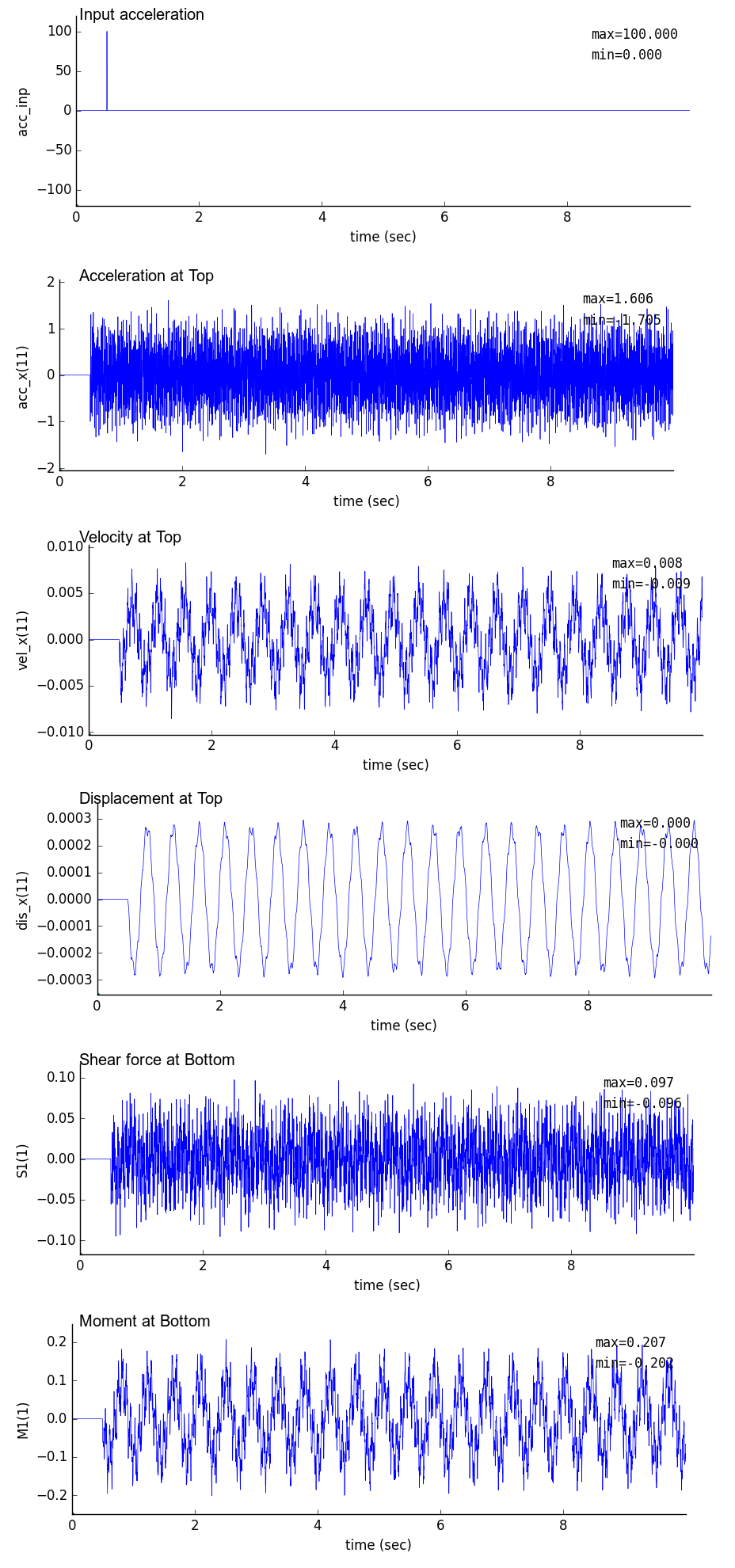

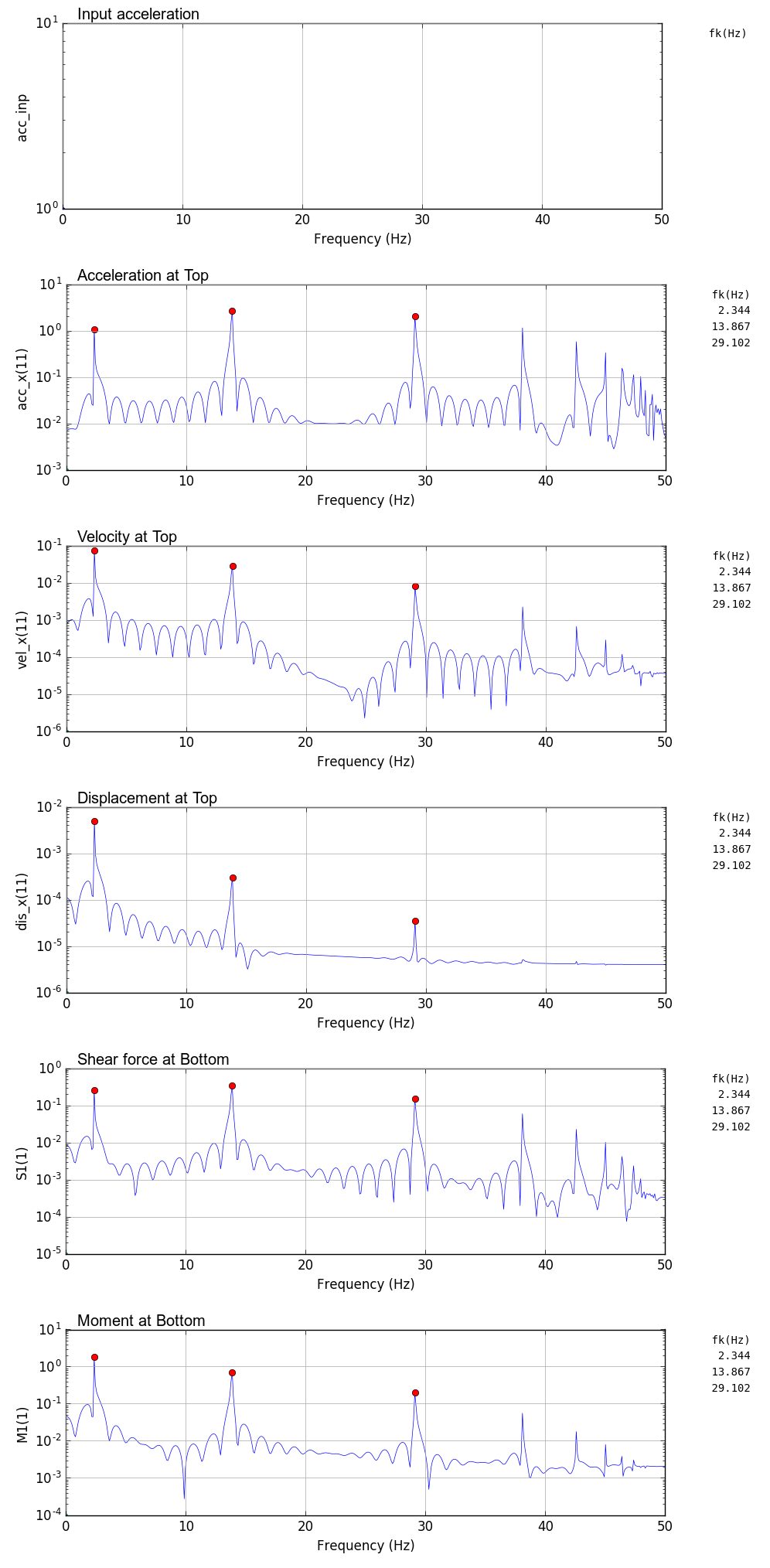

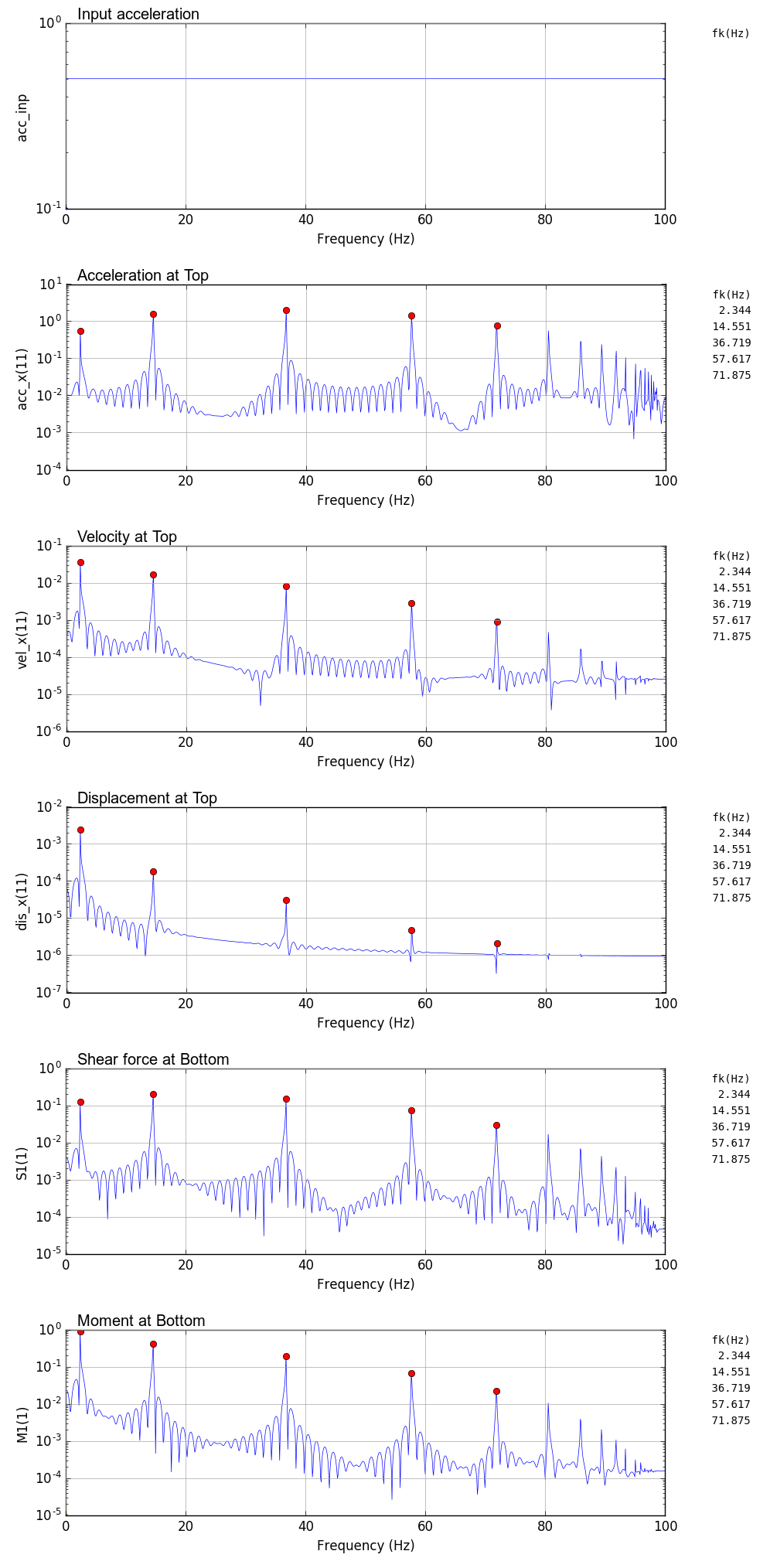

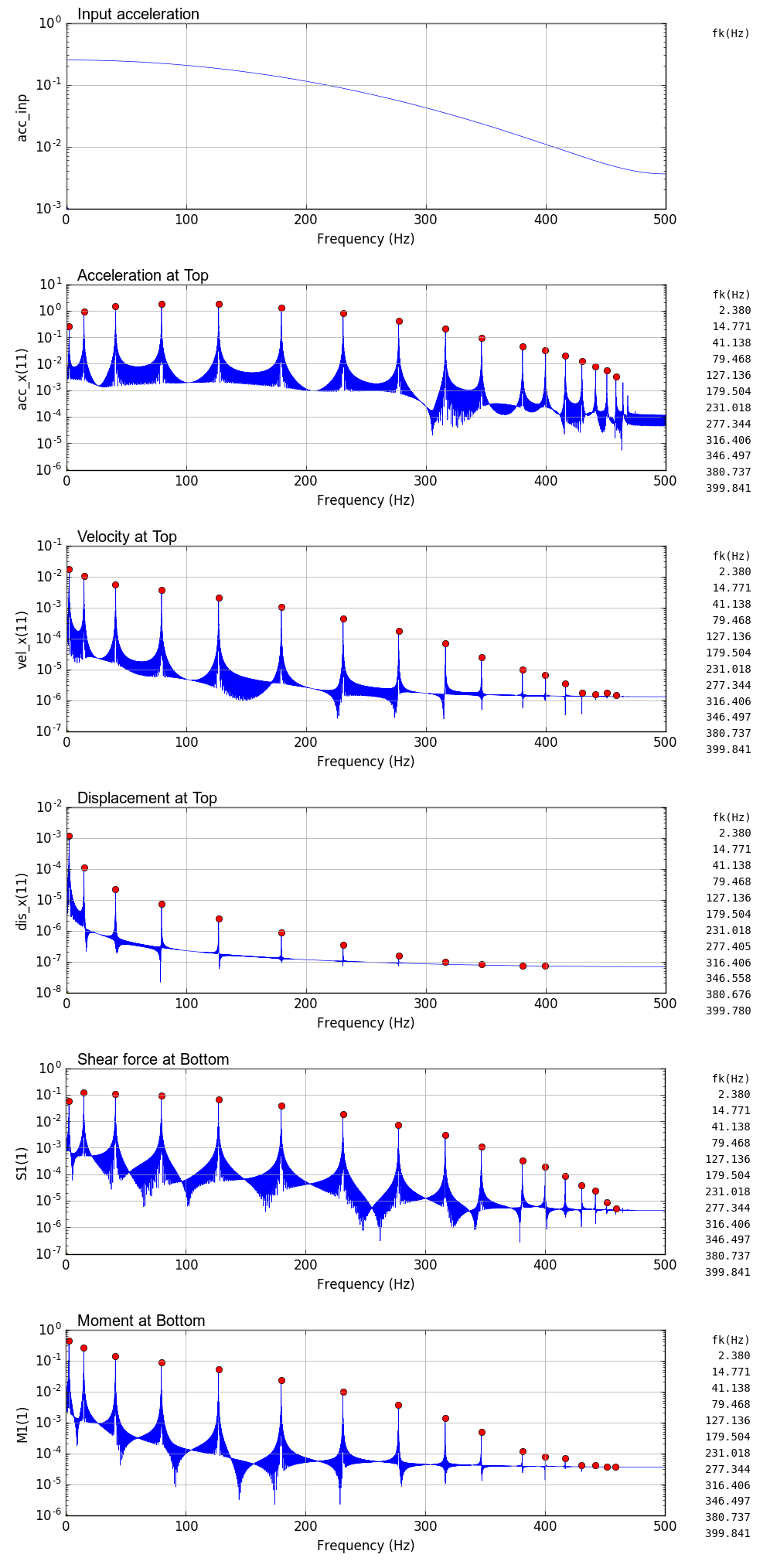

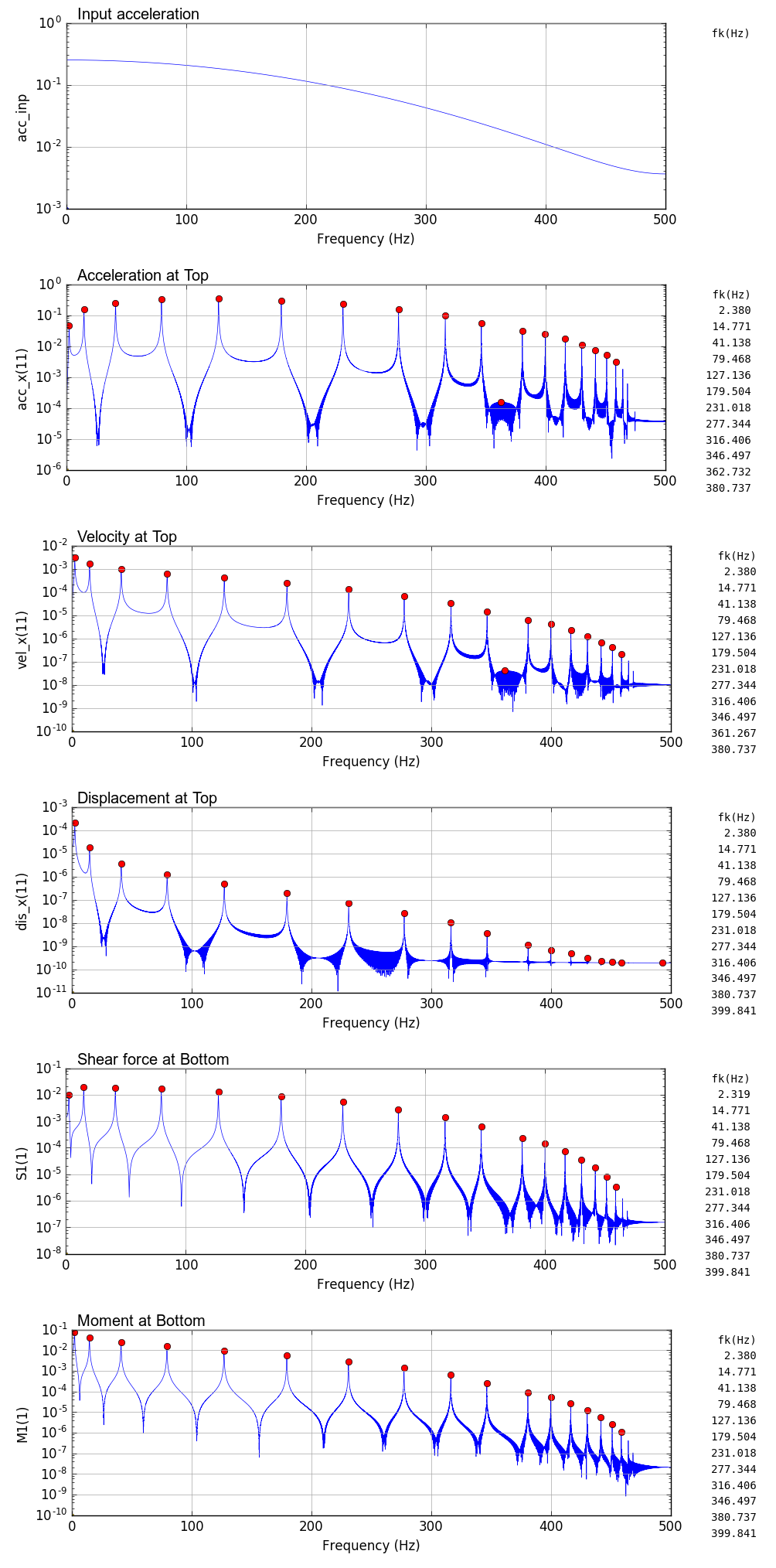

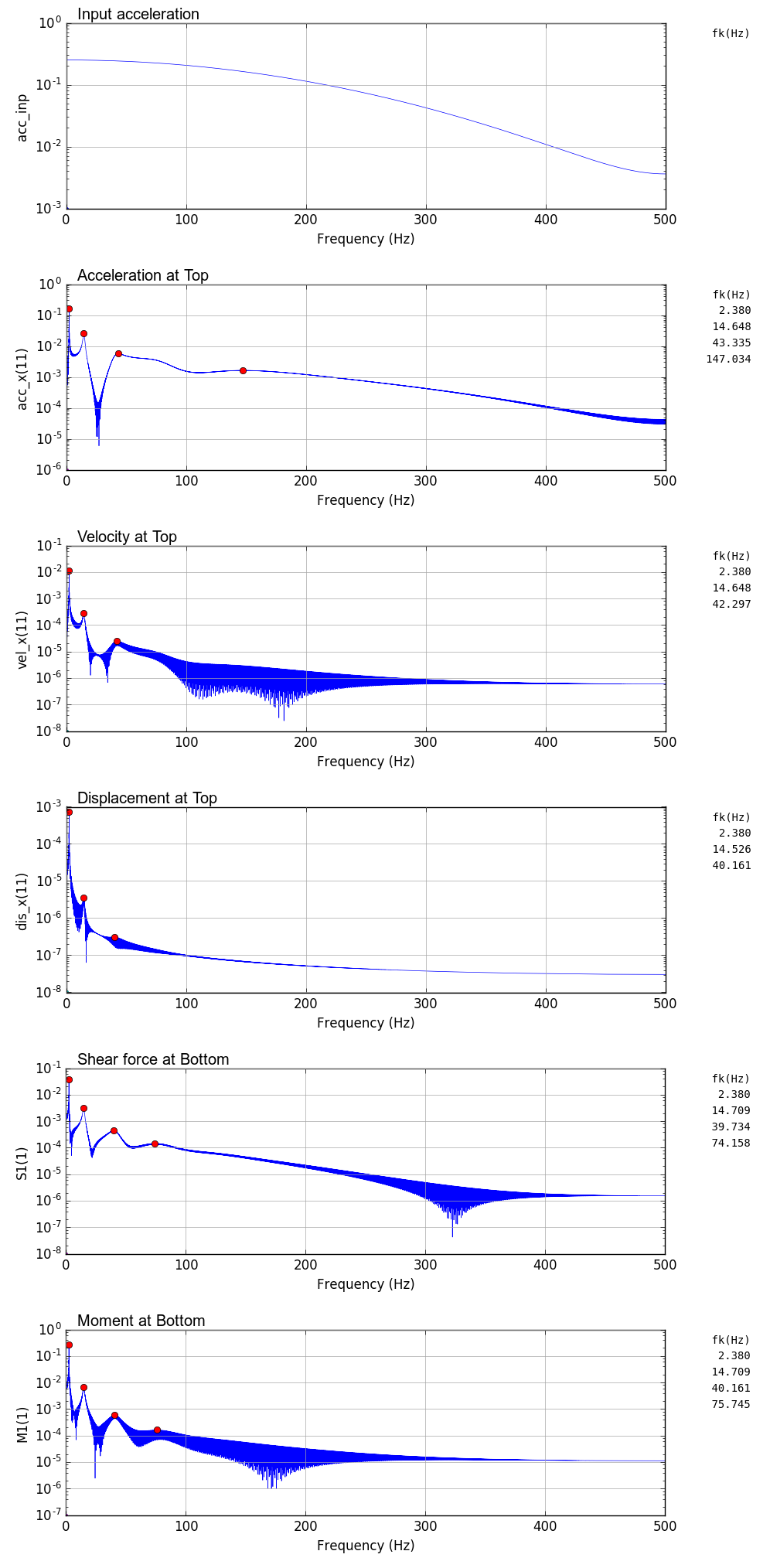

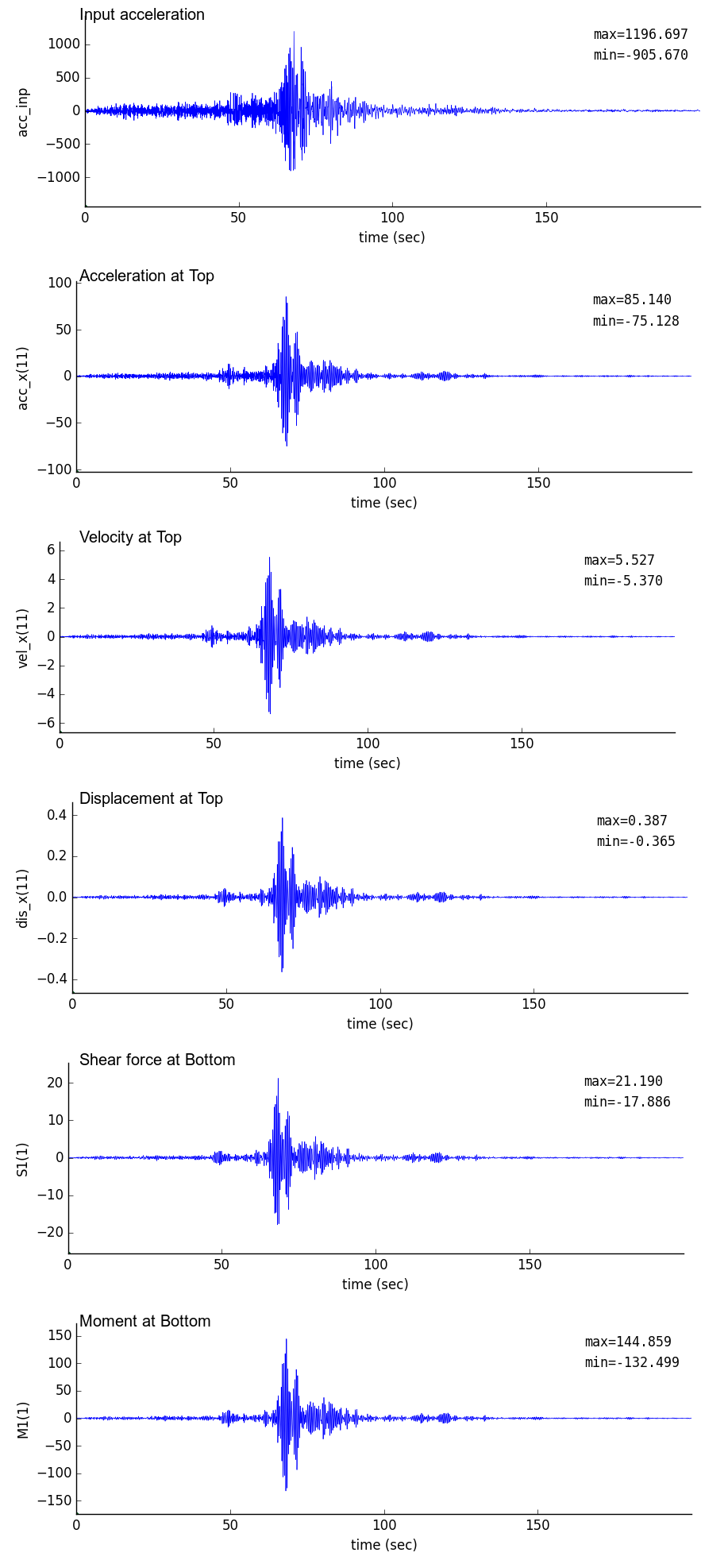

Drawing program for response time history and Fourier spectra (py_fig_vfrm.py)

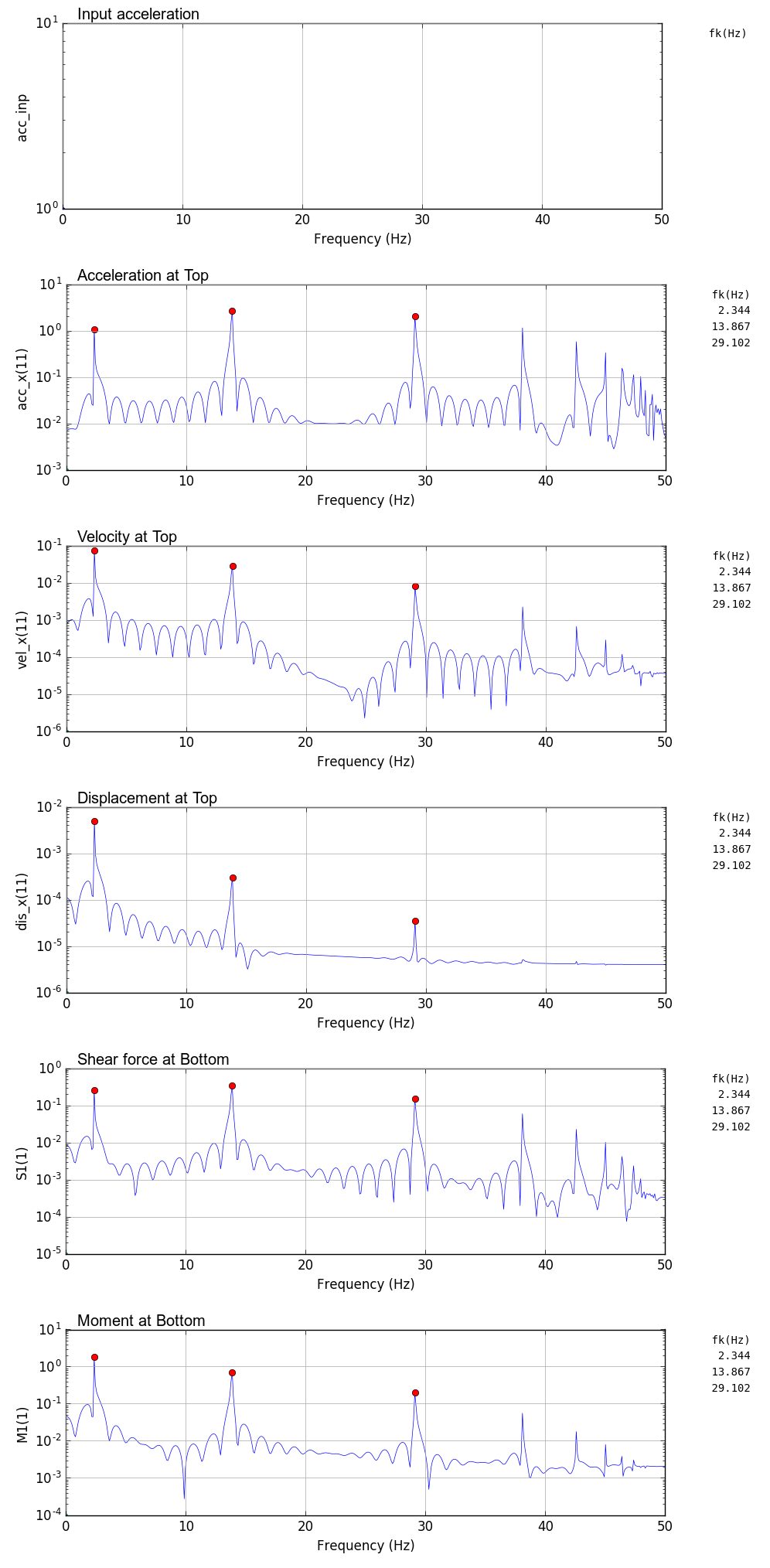

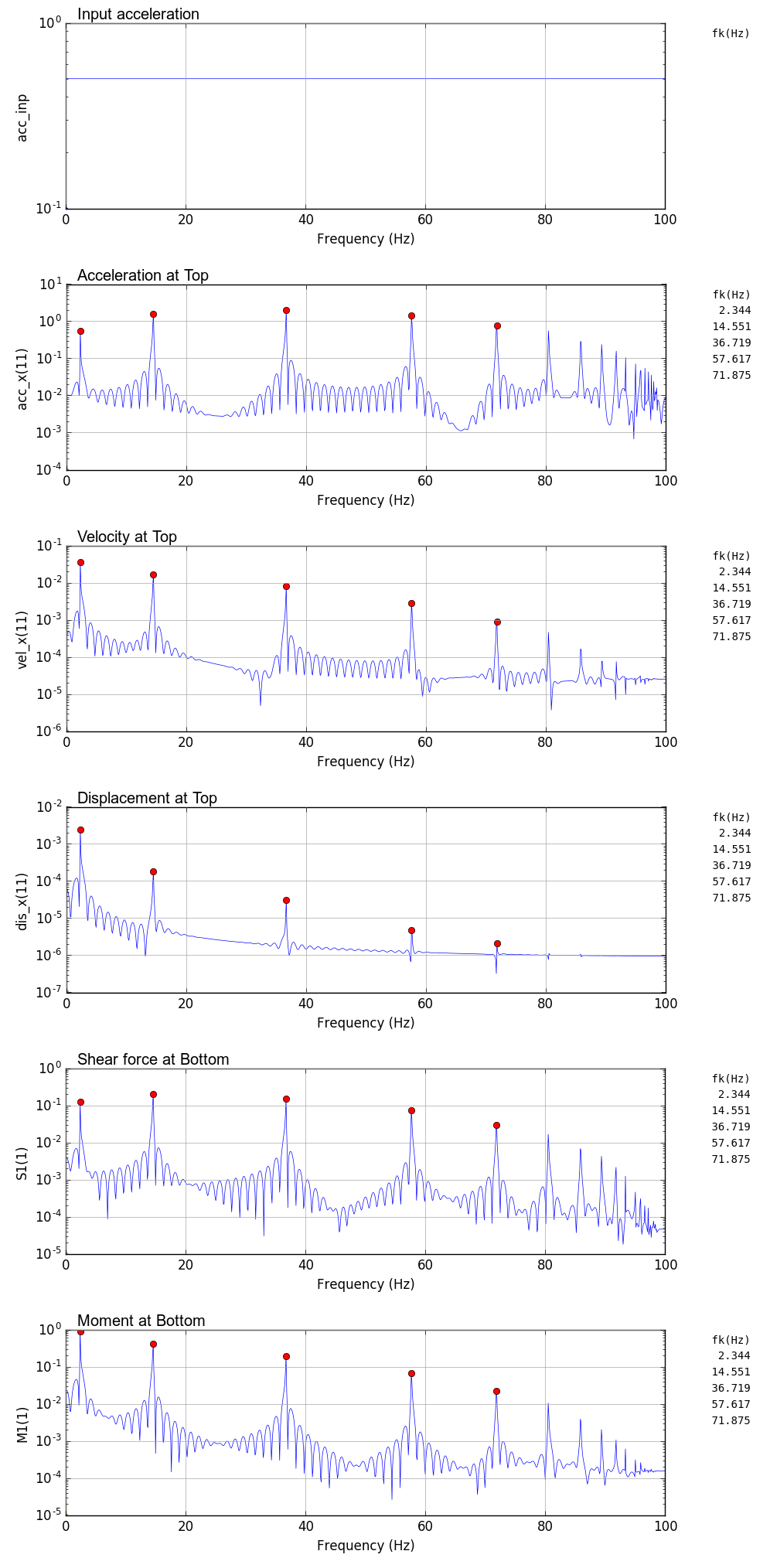

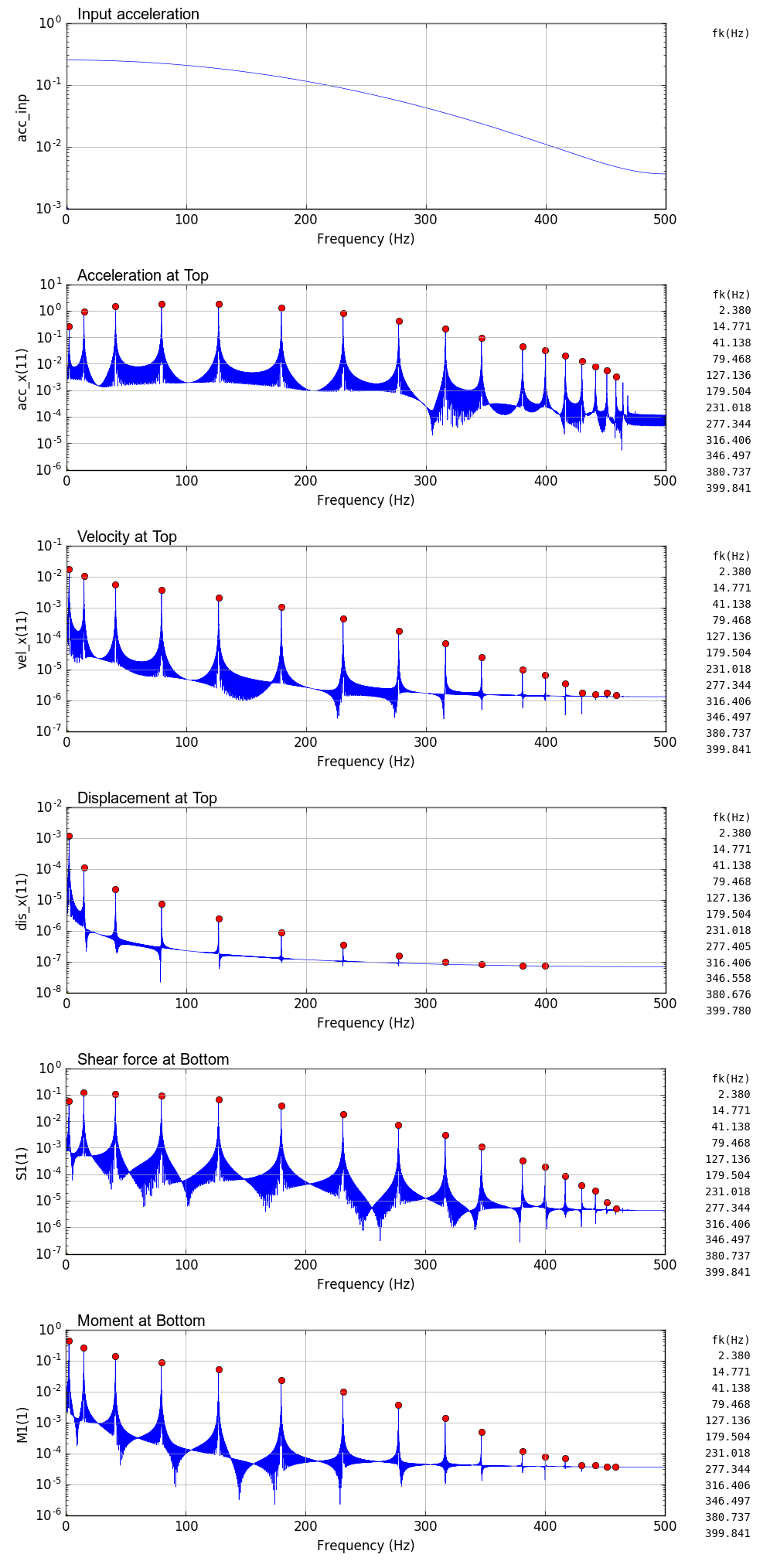

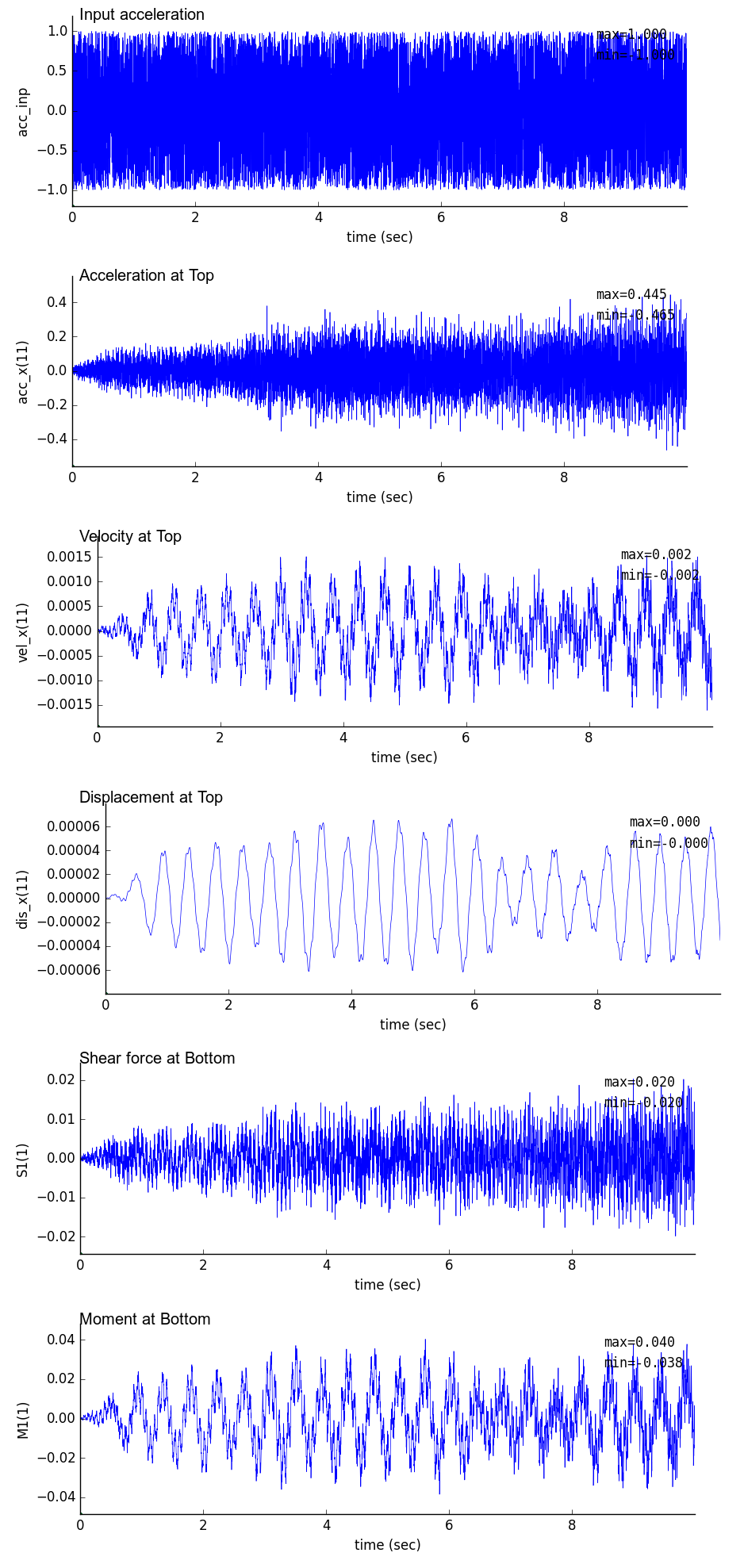

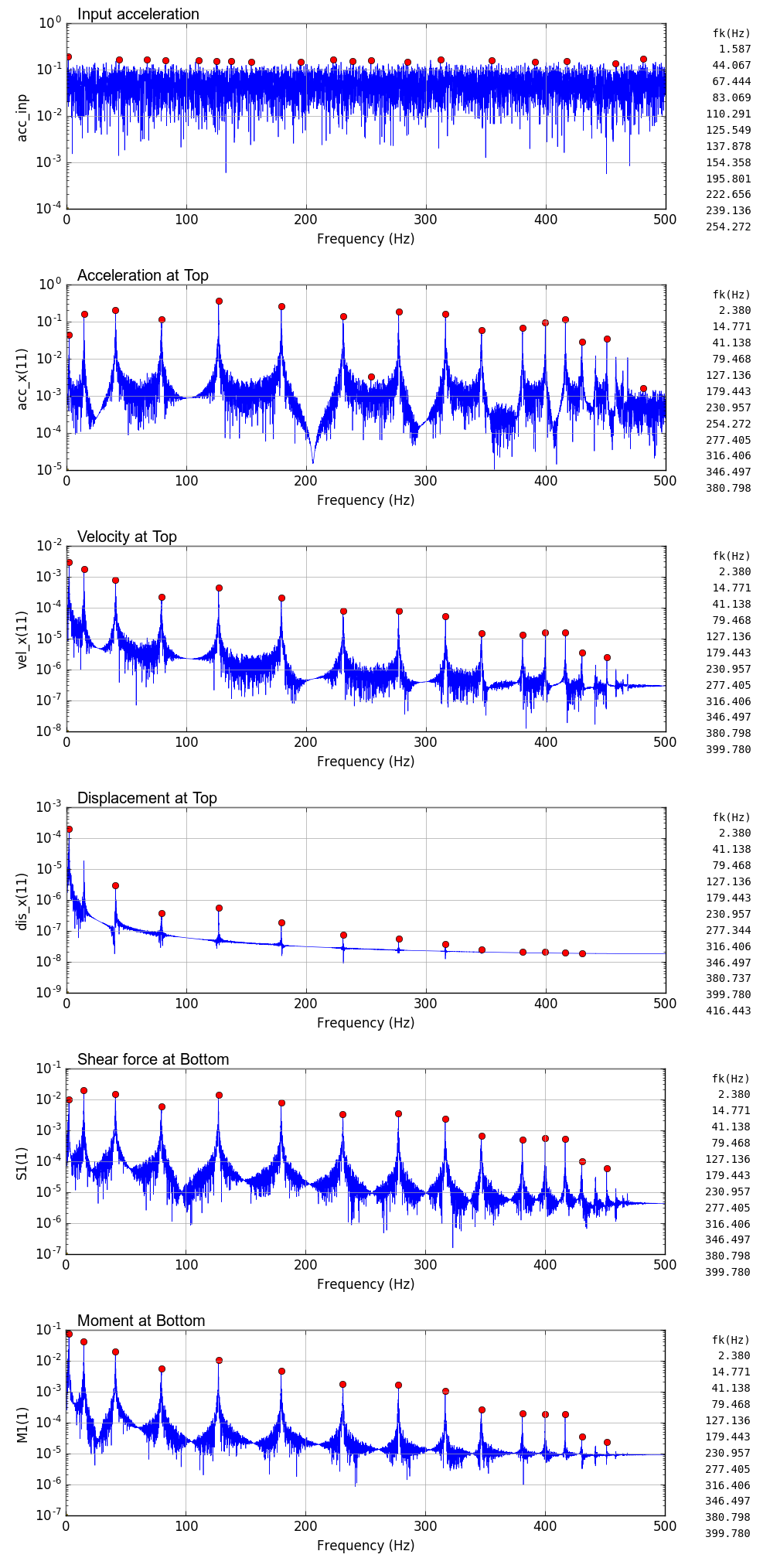

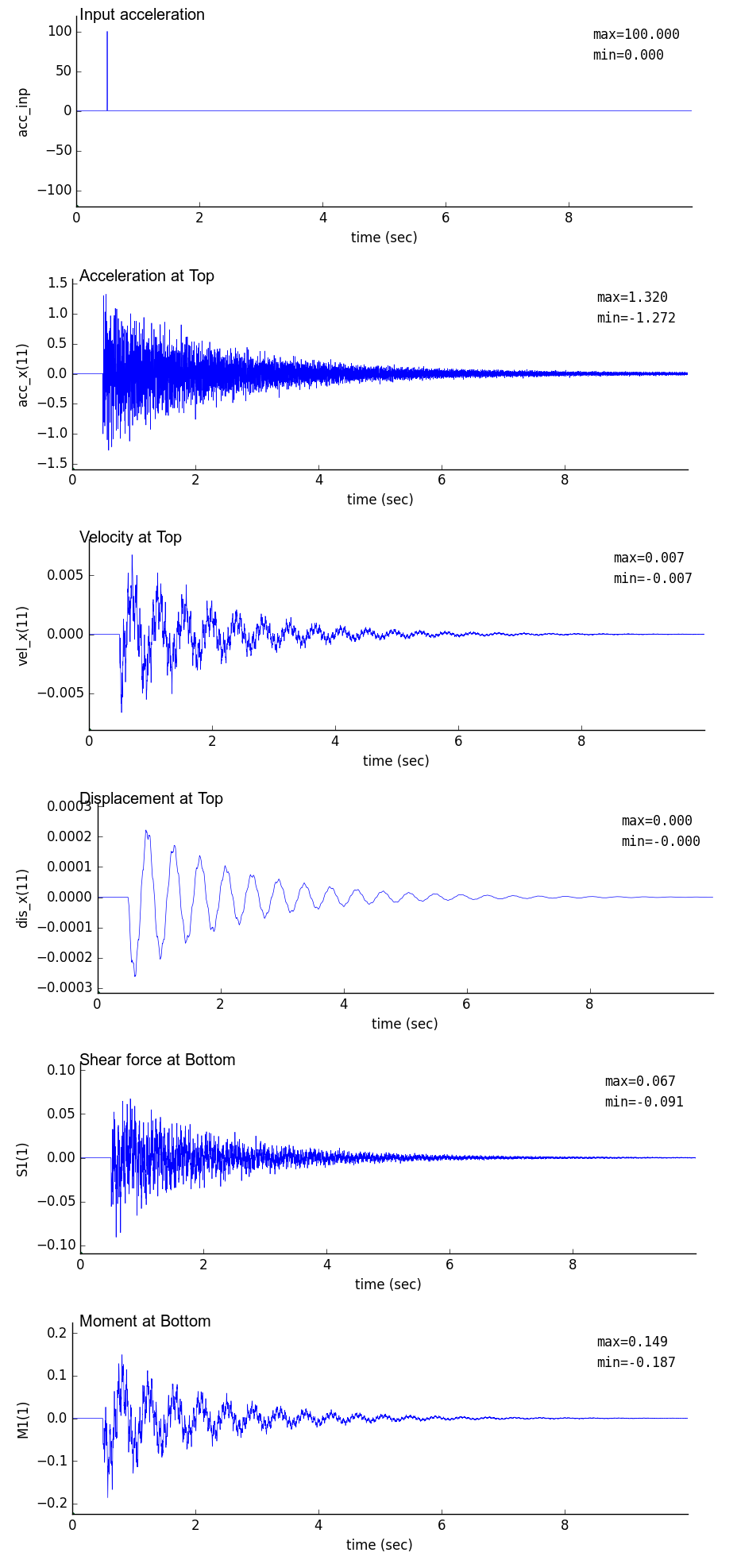

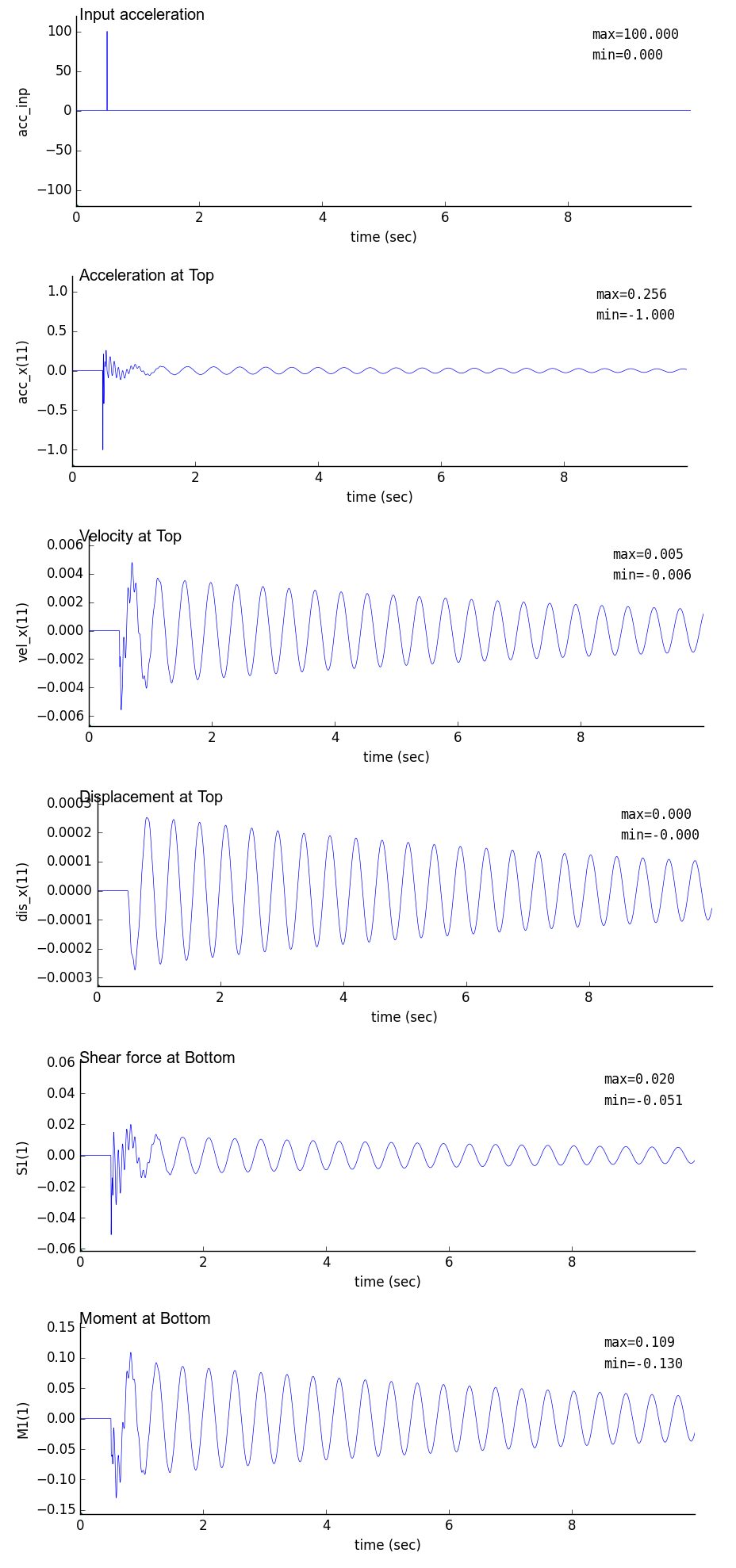

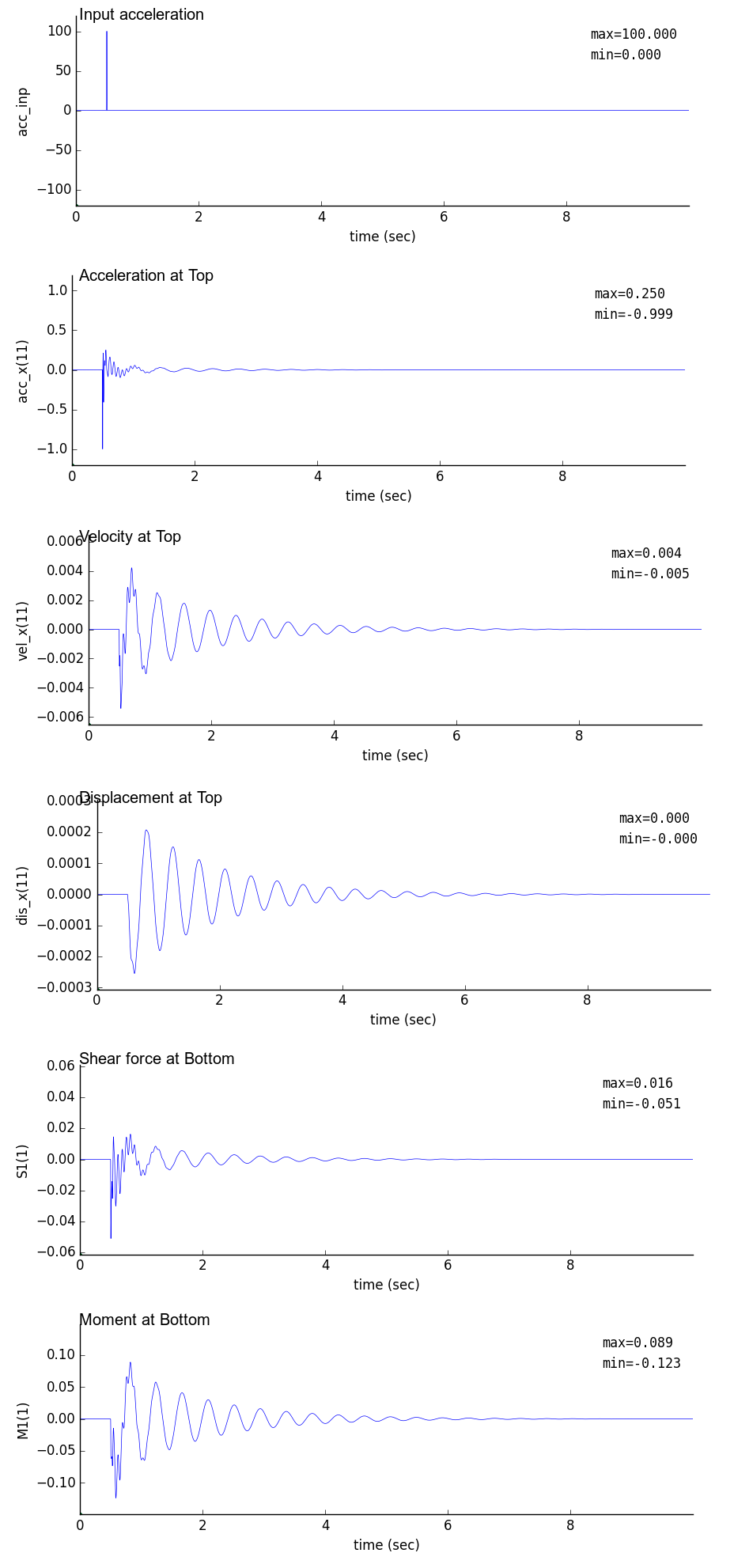

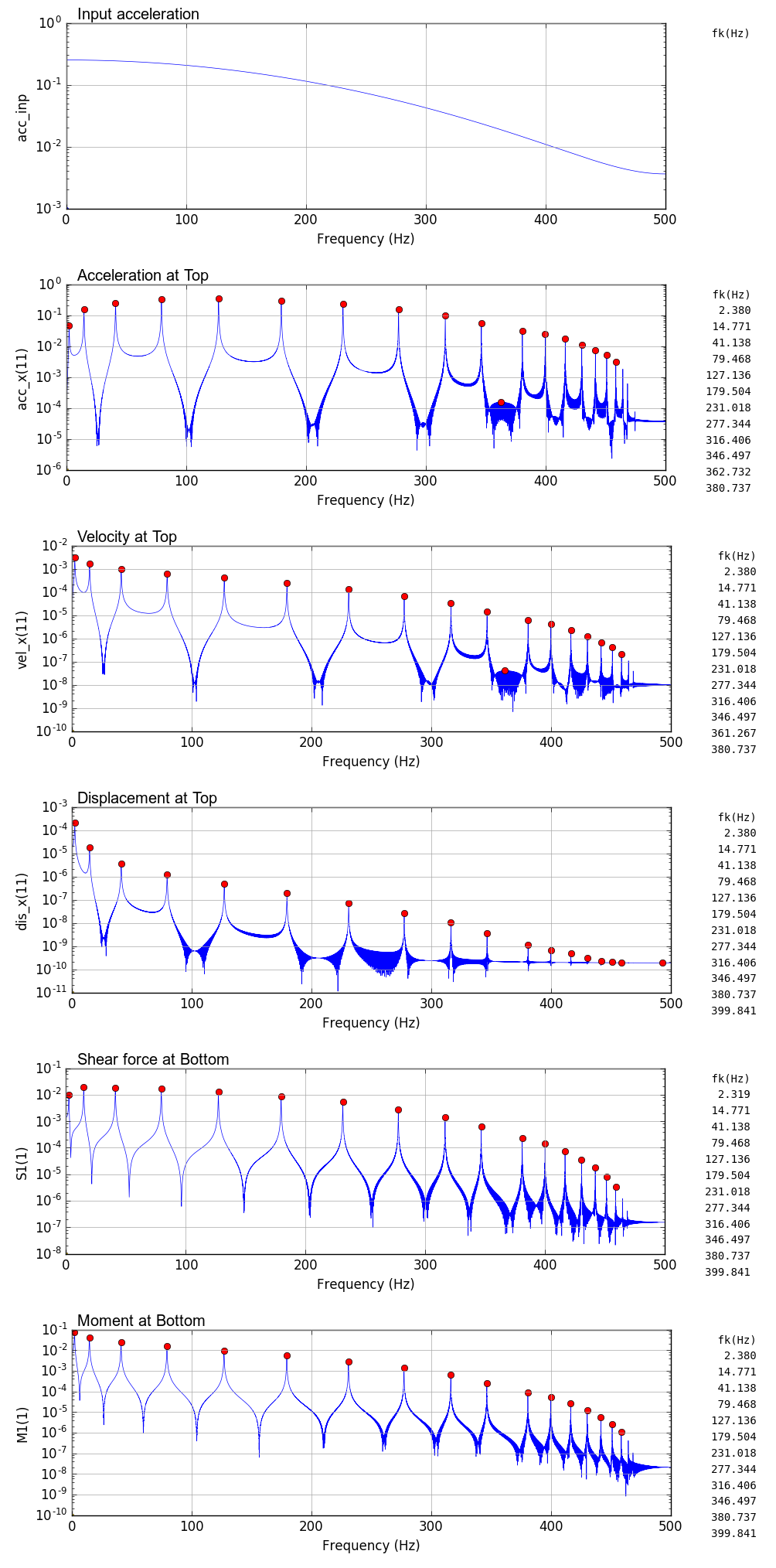

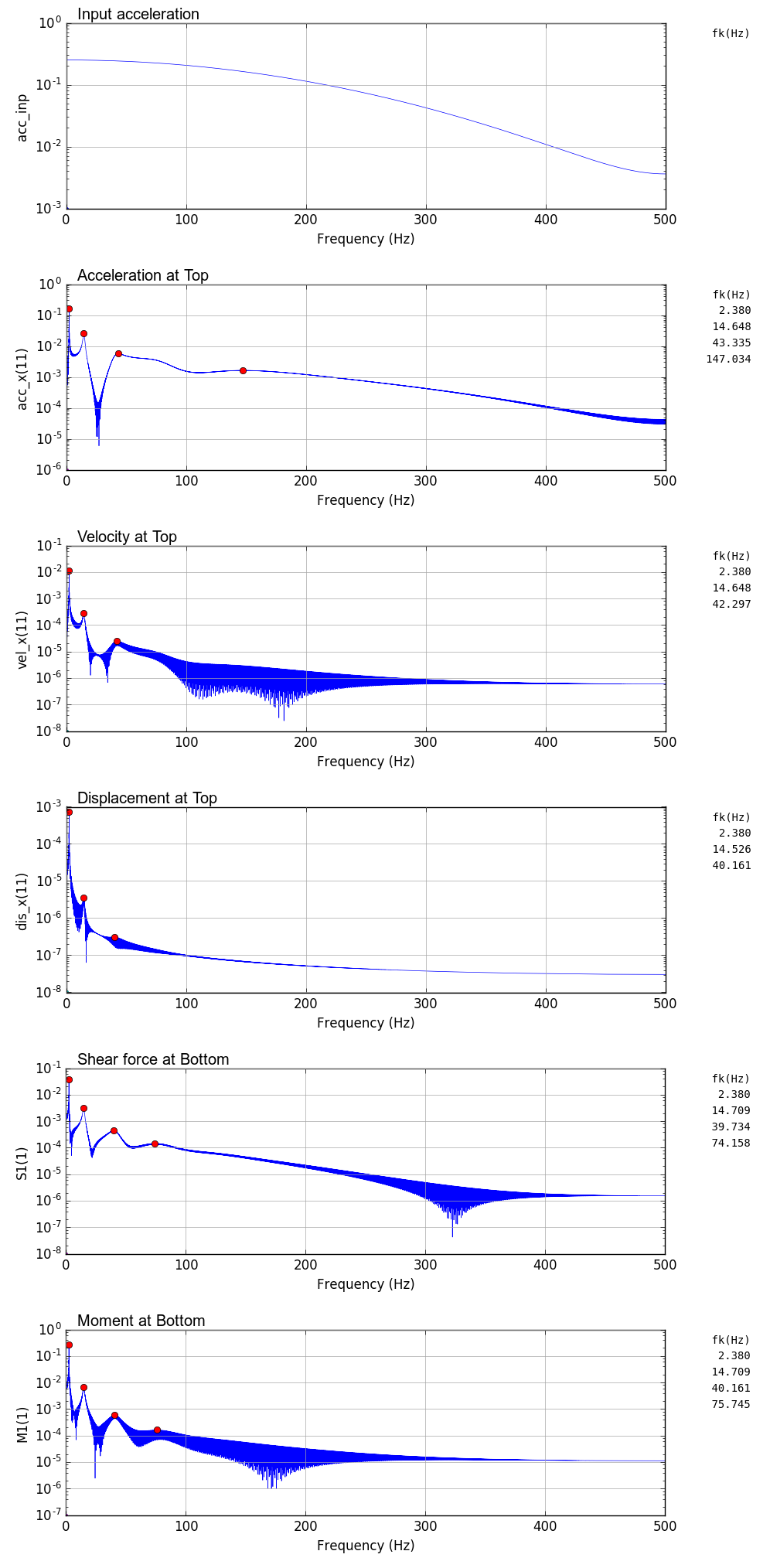

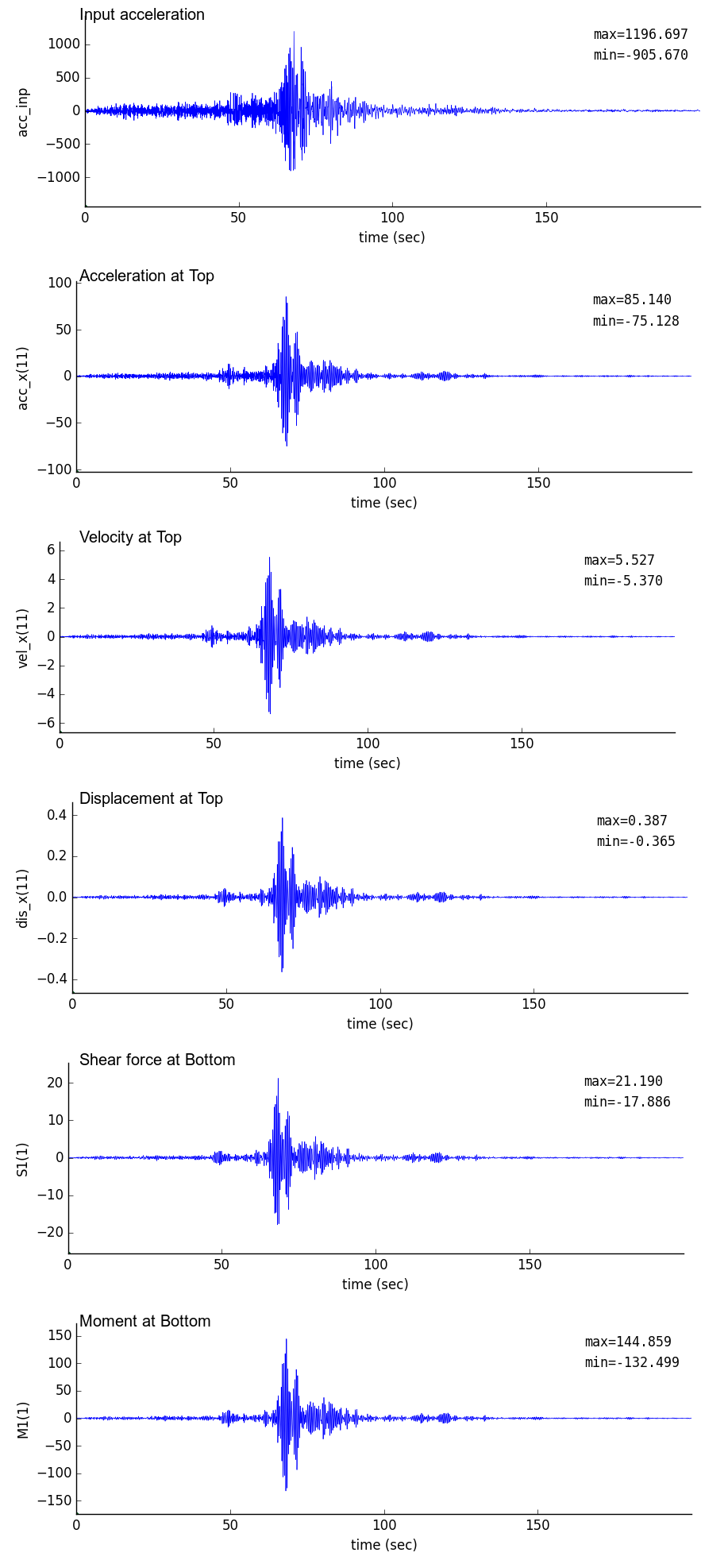

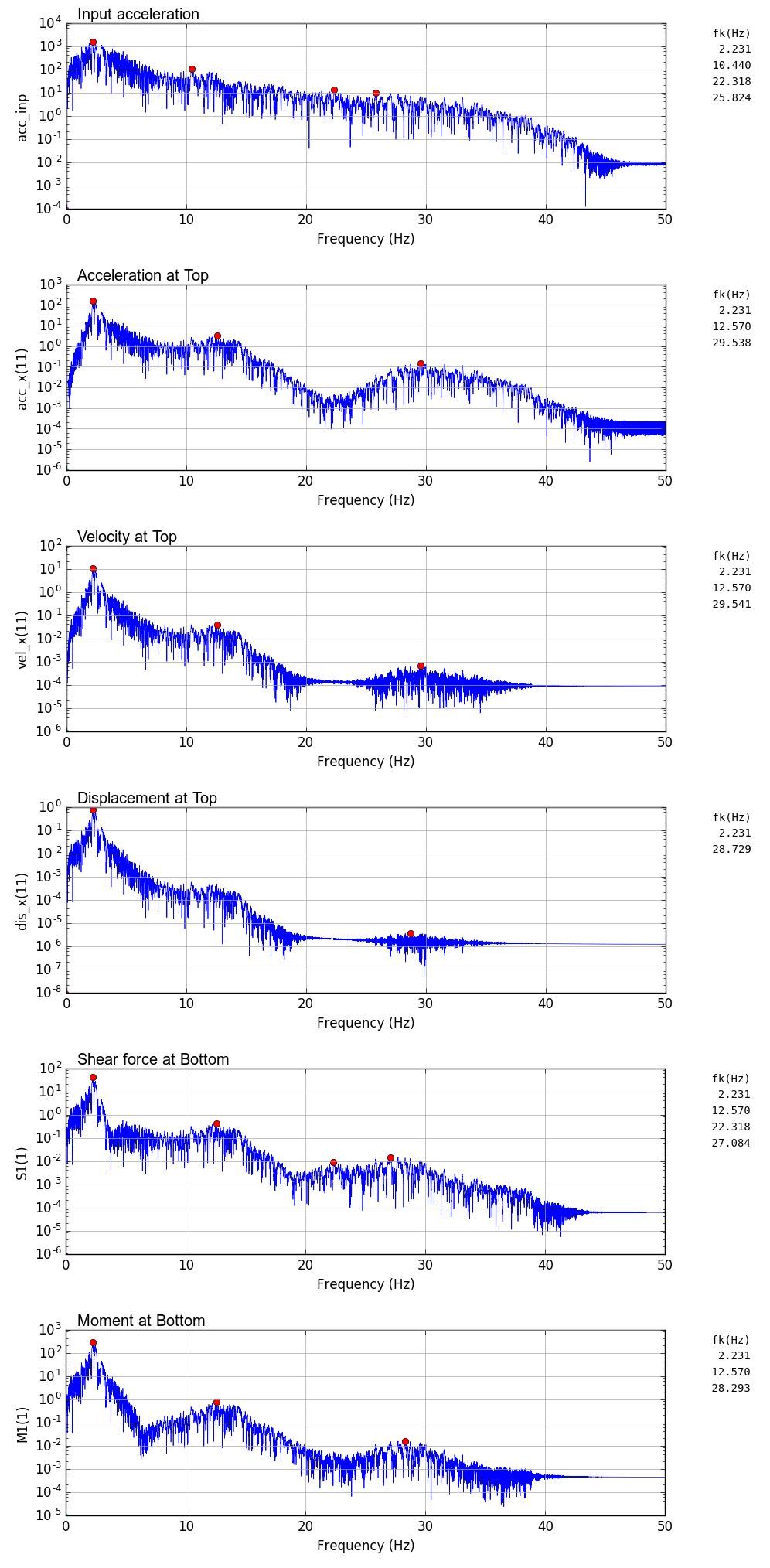

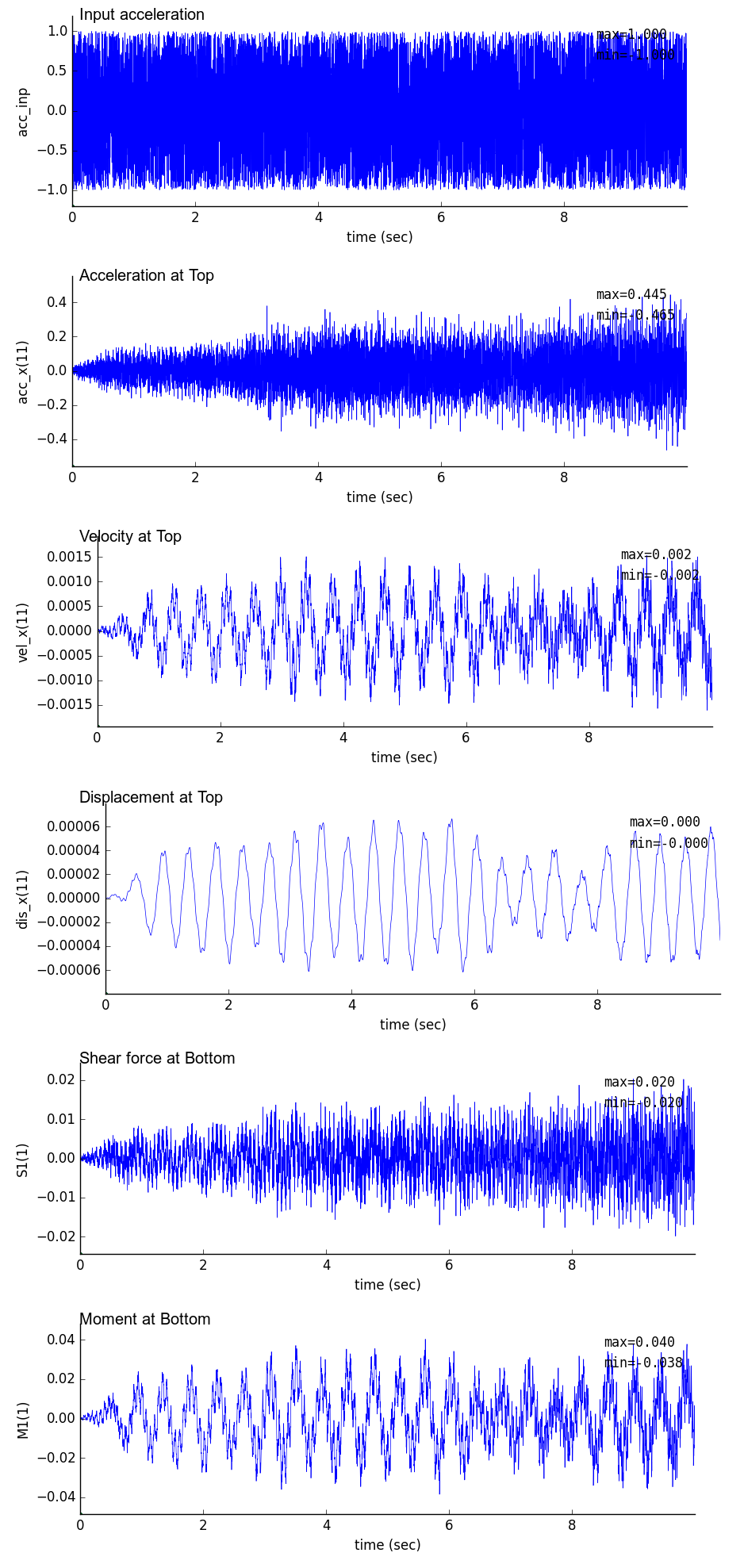

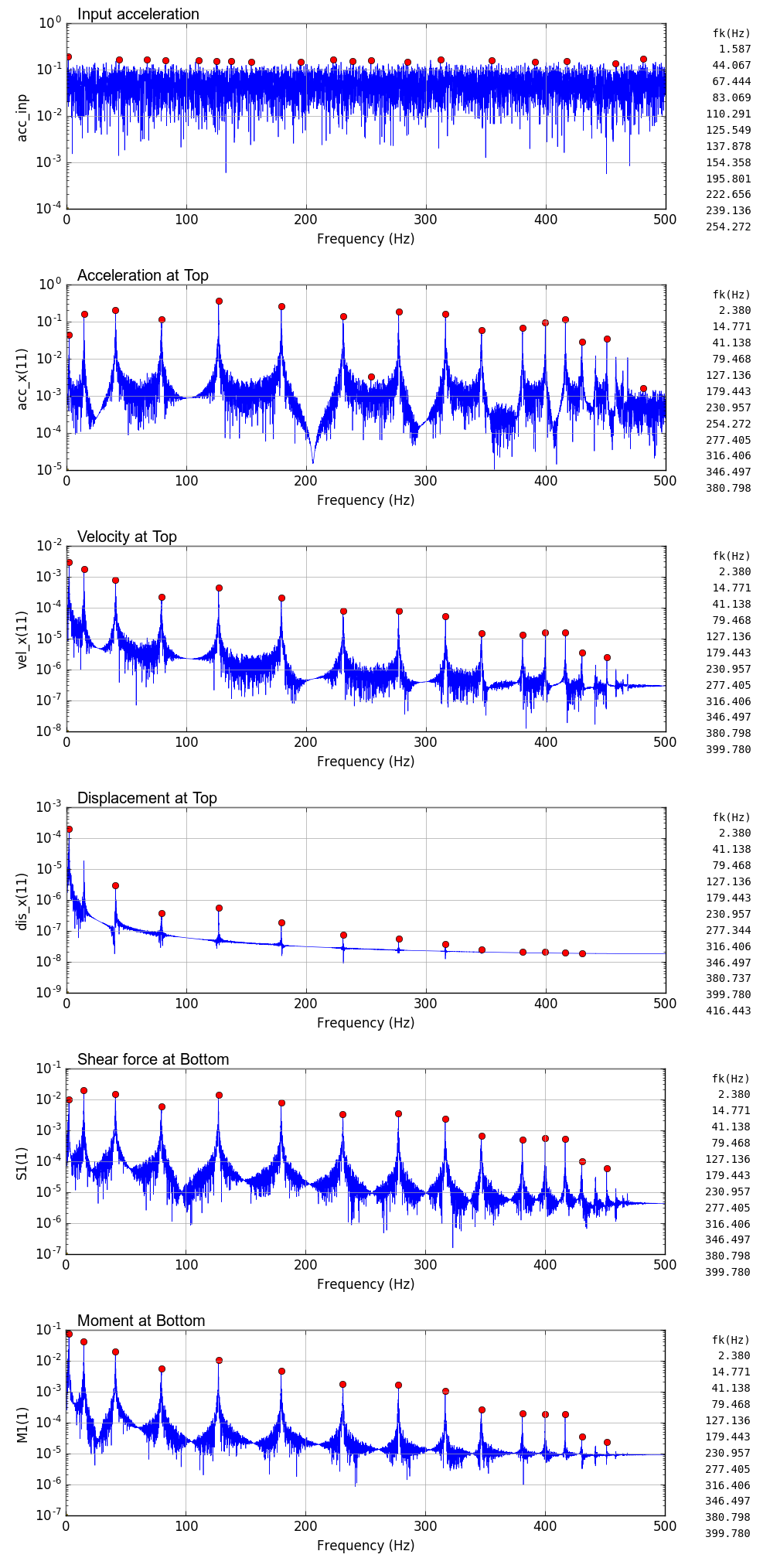

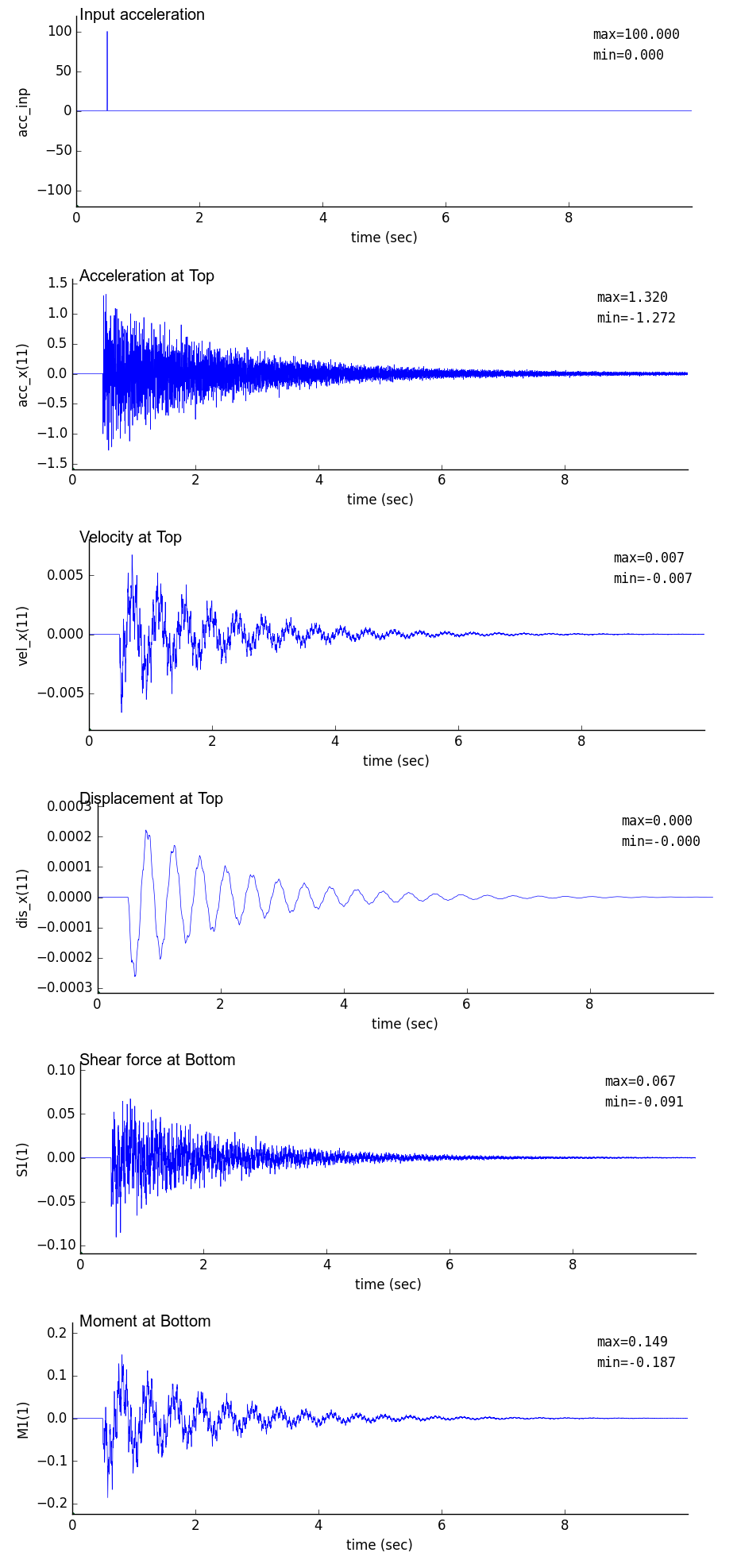

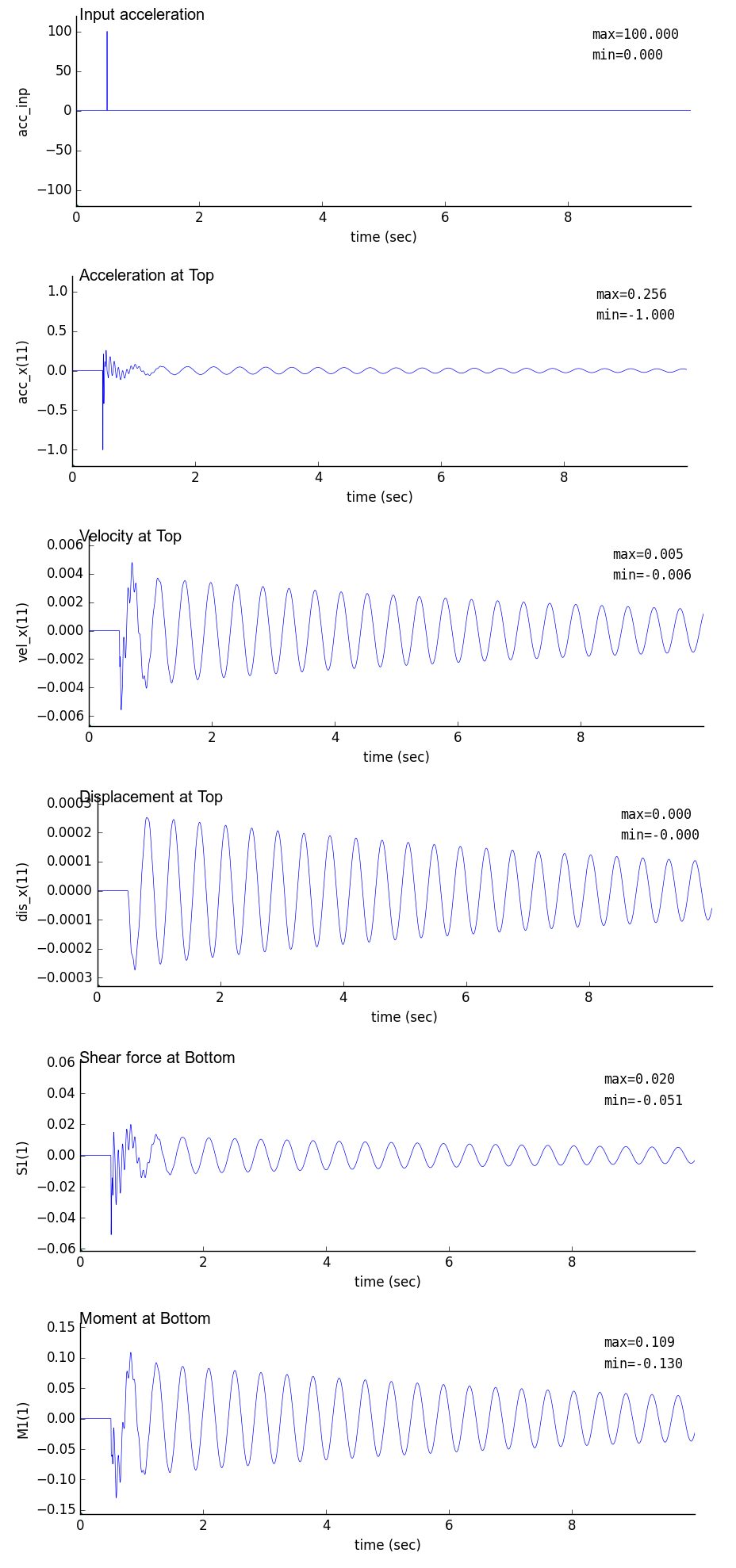

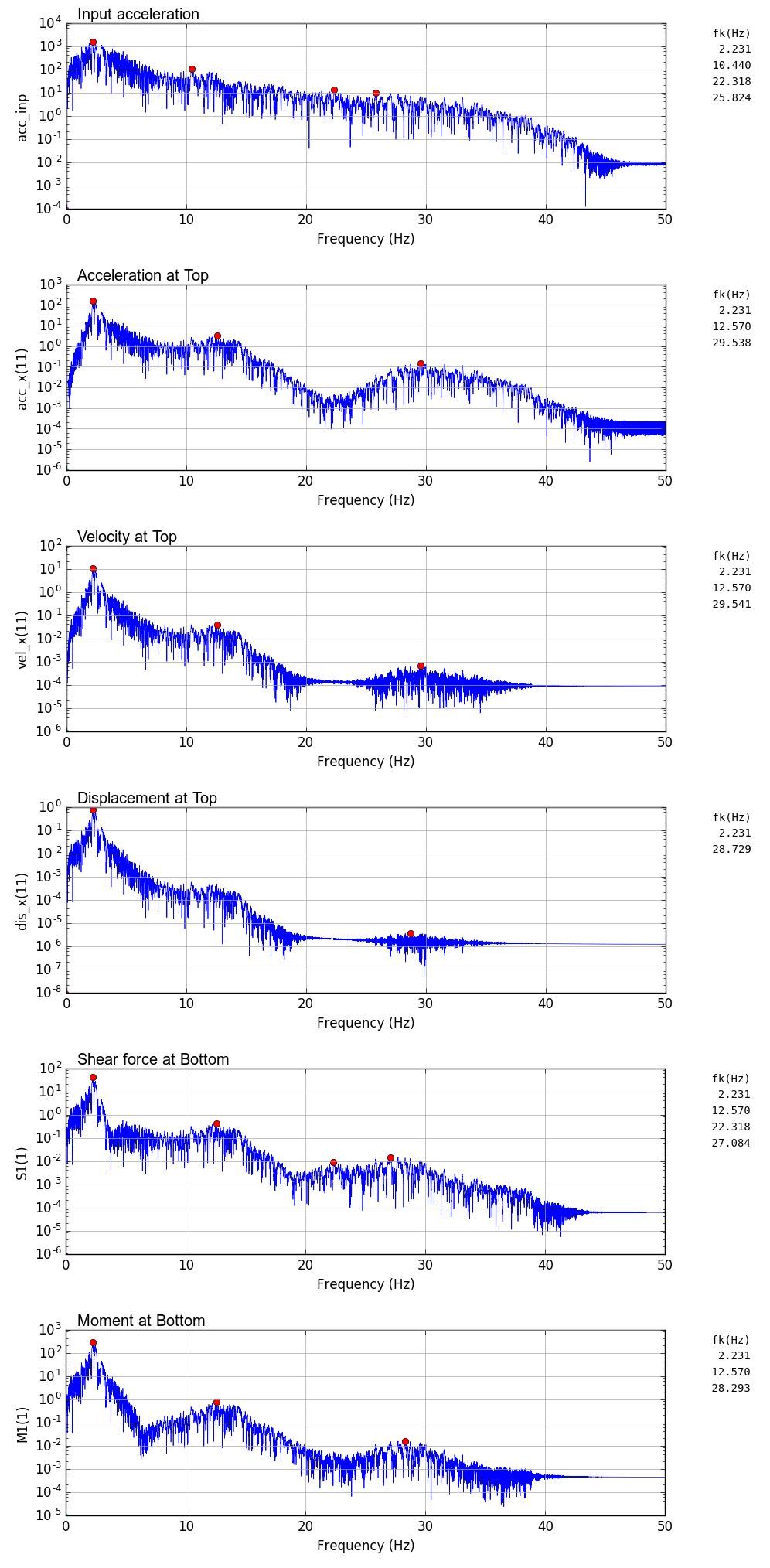

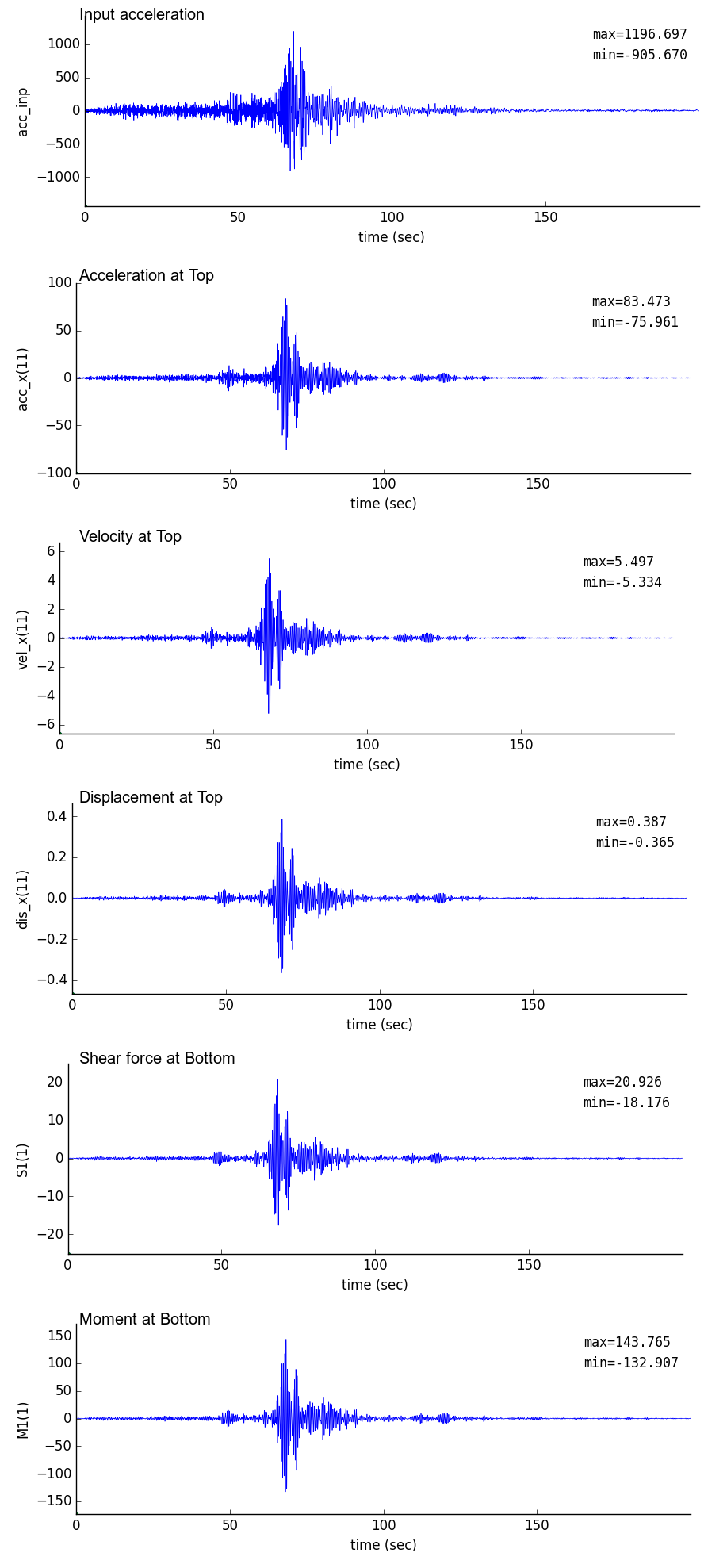

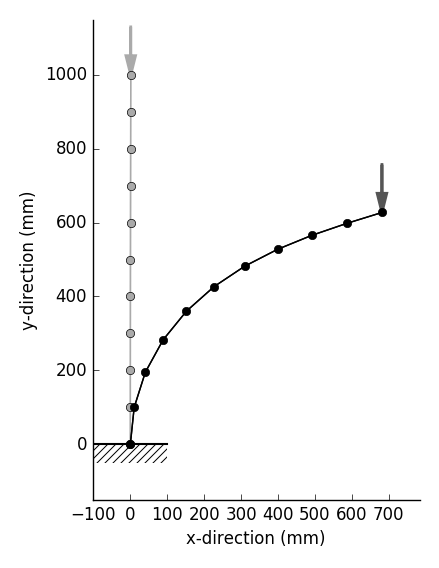

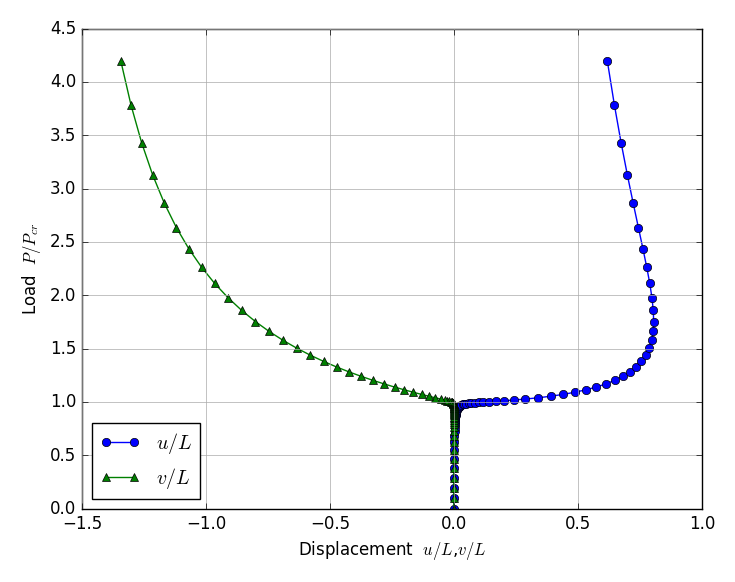

- Drawings of response time histories of node acceleration, velocity, displacement and section forces can be created using matplotlib.